The car, which will be discussed, began to make acquaintance of mine in the late 1980s, when the automotive abundance was not far off, but we did not yet know. However, as soon as he made the frame with pendants, the enthusiasm waned; I had to continue the construction of the car to me. Having estimated the possibilities, I decided to take this job, especially because experiences in such a case I had earlier today I have restored practically from scrap “Moskvich-401”.

The car, which will be discussed, began to make acquaintance of mine in the late 1980s, when the automotive abundance was not far off, but we did not yet know. However, as soon as he made the frame with pendants, the enthusiasm waned; I had to continue the construction of the car to me. Having estimated the possibilities, I decided to take this job, especially because experiences in such a case I had earlier today I have restored practically from scrap “Moskvich-401”.

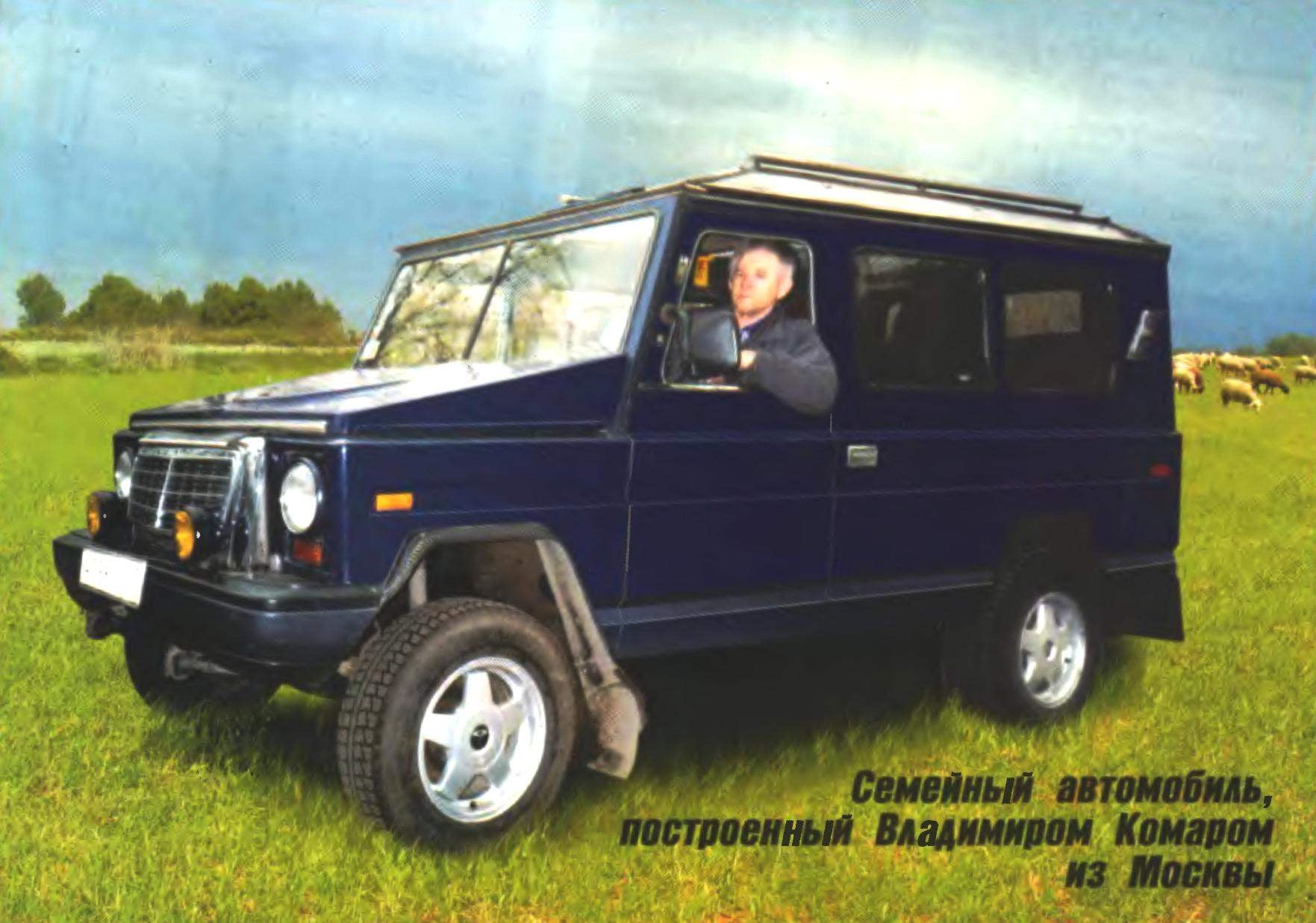

In ideas I wanted to build a car roomy, simple and reliable: to travel to the country or to travel space enough for all family members and even the required load you can carry. Made frame, it is allowed to make such a machine.

The body decided to fiberglass applied to the wall — he’s more durable. Complex forms of body panels (as they say — surfaces with double curvature) tried to avoid even in sketchy outline: them to draw something difficult, and even more to do At the same time we wanted the car looked good. This tried to achieve precision performance auto body trim parts, especially exterior.

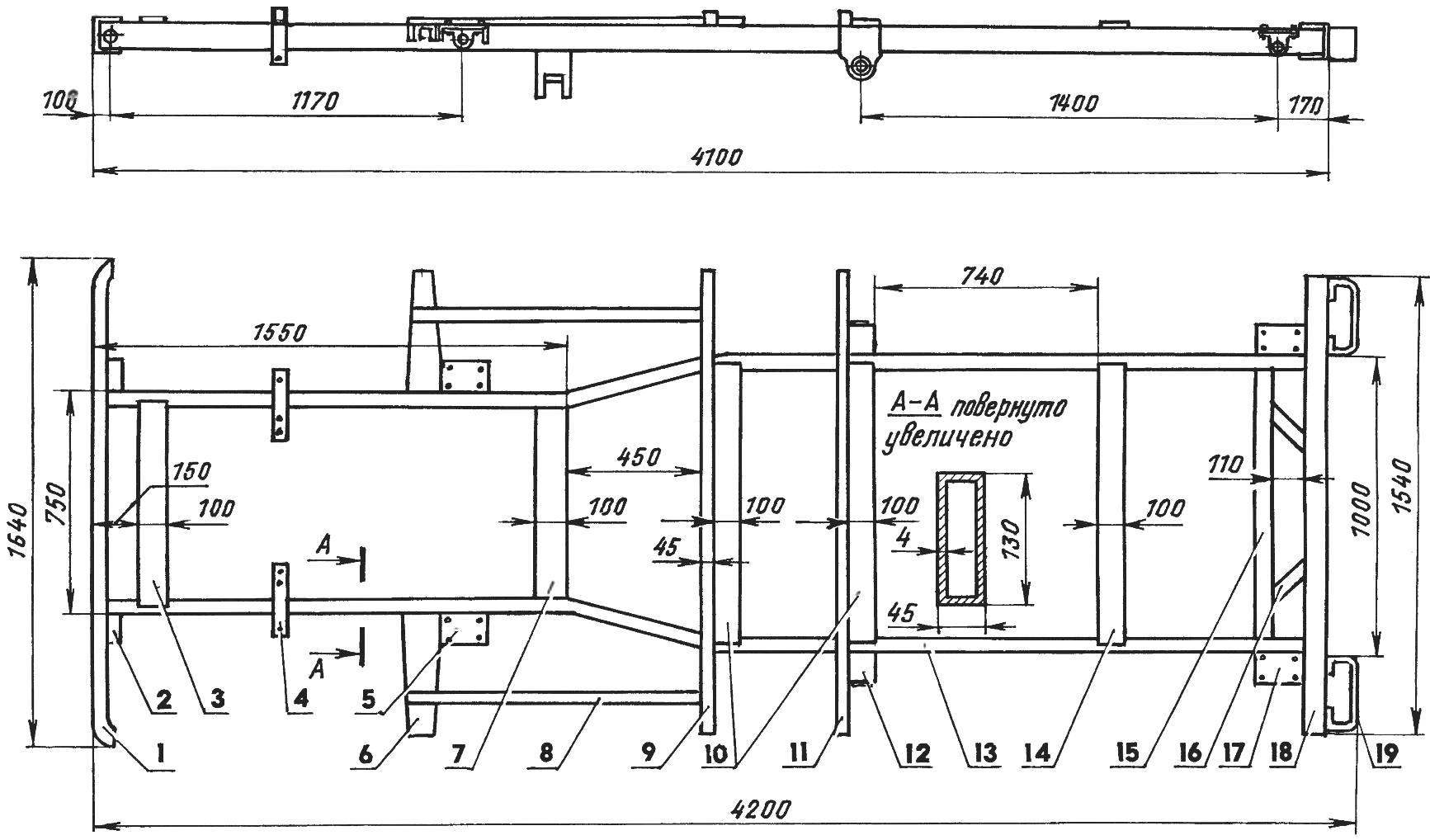

As a rule, — the chassis or the chassis completely, homebrew take on a certain car. I have a “affection” was not. The basis can be considered a whole family gazovskih cars. The engine of the “Volga” GAZ-24-10, gear shift, steering and rear axle from the “Gazelle” GAZ-3302, front axle — all UAZ-451 (once such machines with only one rear axle was produced at the Ulyanovsk automobile plant). There were other components and mechanisms from other machines. So, the front suspension (springs and dampers) — from “the Muscovite-412”, the rear suspension from “Gazelle”.

The driver’s seat. The instrument panel is small but everything you need to control units of the machine it is

The back door is hinged and wide. The Luggage compartment is non-insulated and roomy

Many homebrew built their machines in a cooperative garages. I do not have such. And therefore asked the leadership of the fleet, which worked, making the machine on site after work and on weekends. The permission was granted, and we (me and son) took over. Colleagues have seen — do we have enough patience to make the car what it is. Many have offered help.

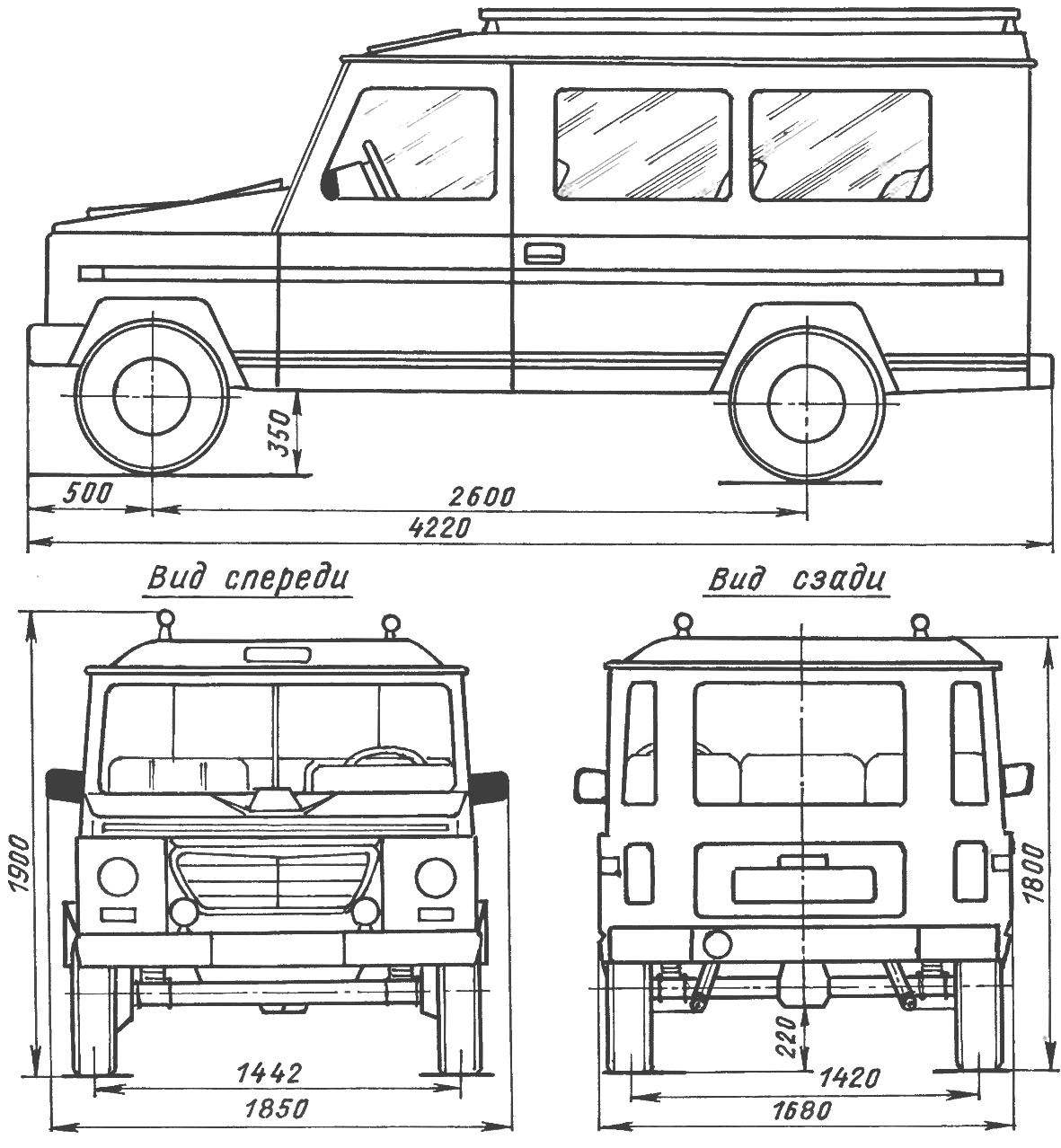

The machine frame is rather simple (not even space), dvuhkonturniy — wider behind and narrower in front. The spars are made of steel (vs) of a closed rectangular profile dimensions 130×45 mm and a thickness of 4 mm profile Size was calculated by experts for maximum bending moment with a large margin of safety. The profile adopted is the same along the entire length to facilitate manufacture, the frame and field Spars connected welded them several cross-beams, and front and rear bumpers. Crossmember — from steel strips 100×5 mm. Front bumper borrowed from decommissioned UAZ-469 and covered by a decorative plastic trim, and the back is made of channel No. 15 is equipped with a tow bar and the edge buffers. The car was able to tow a trailer, the rear bumper is reinforced with additional cross member struts.

To install the body on the frame welded to it on both sides of the pair of (symmetrically located) console, and in the middle of the frame — podgotovka beam. Mounting frame to the frame is carried out by bolts M10 (using rubber gaskets).

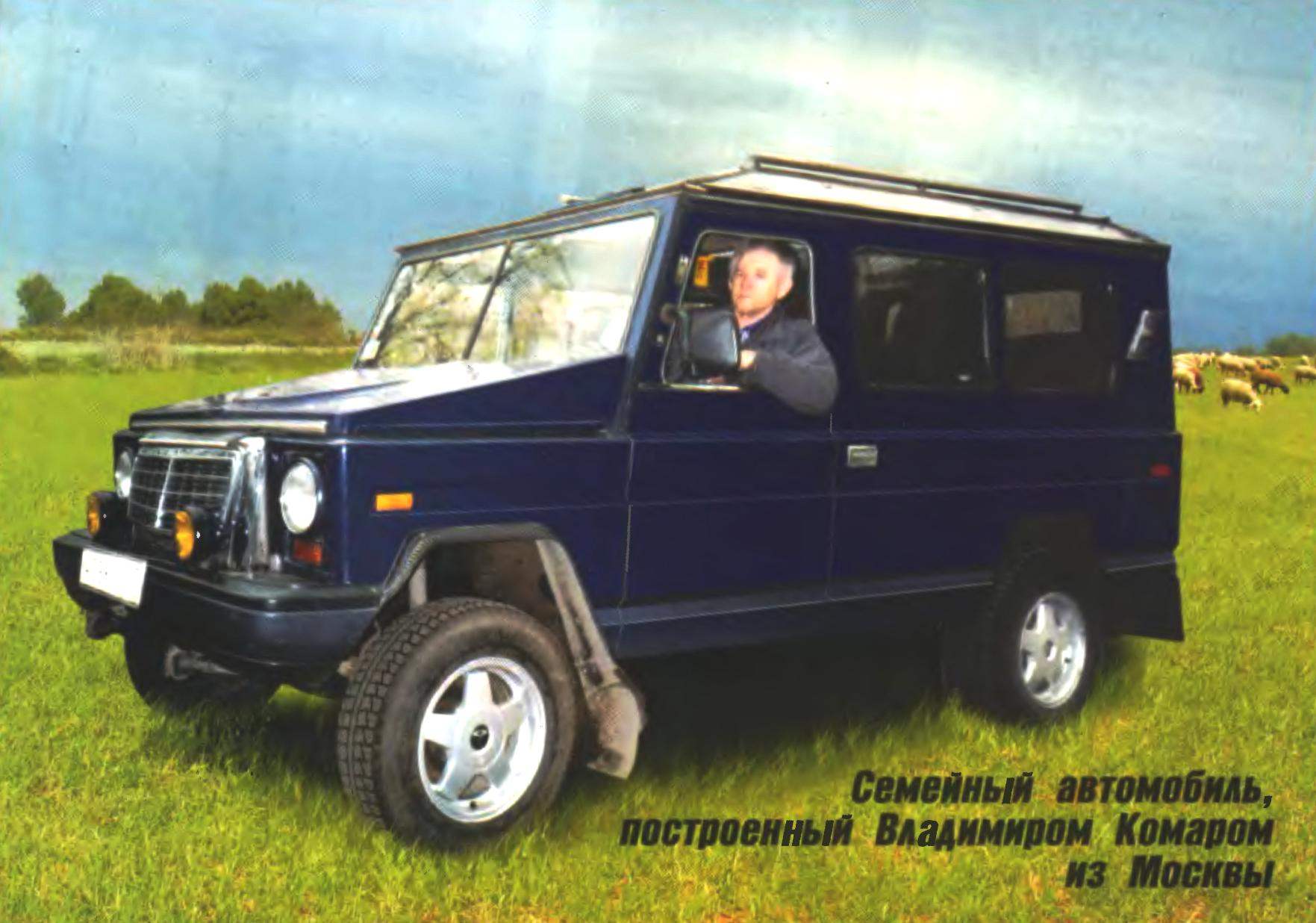

The geometric scheme of the car

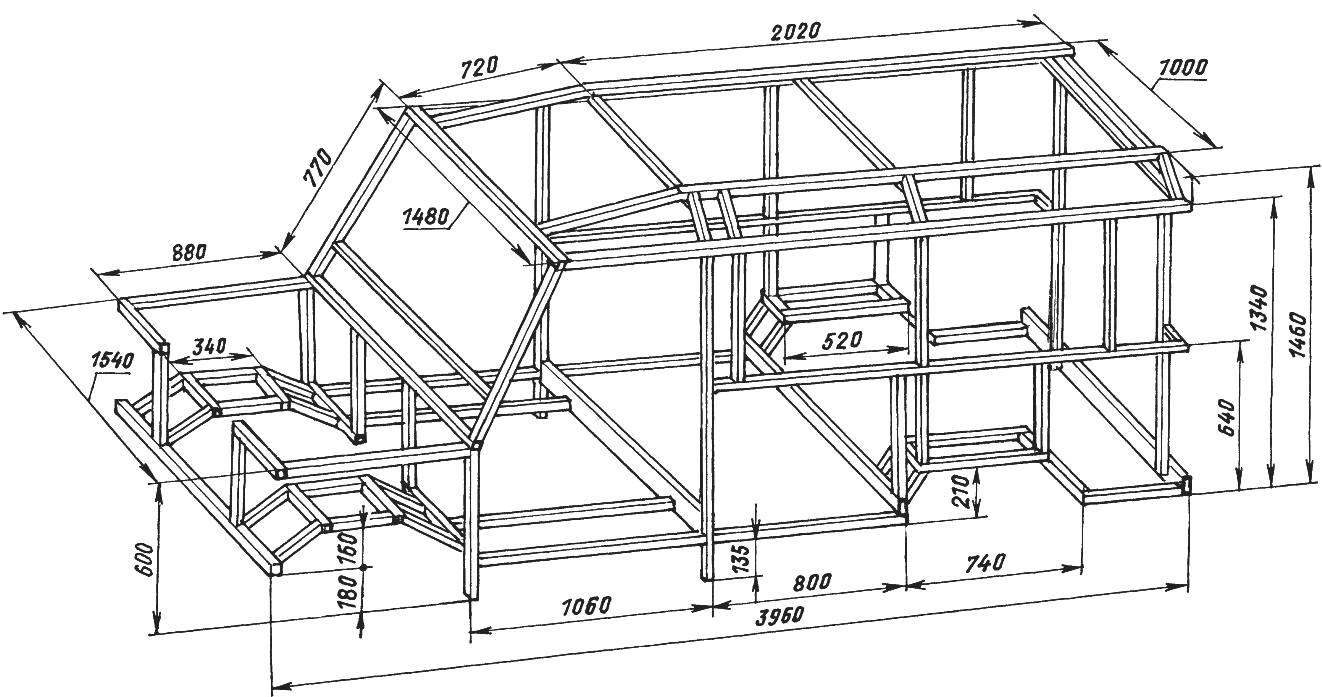

Frame:

1 — front bumper (from a UAZ-469 vehicle with plastic cladding); 2 — fixing bracket front spring (from “Moskvich-412”, 2); 3 — front cross member (steel strip 100×5); 4 — bracket engine mount (2 PCs); 5 — bracket and the axis of the earrings front spring (from “Moskvich-412”, 2); 6 — front console mounting of the body shell; 7 — beam suspension the gearbox and transmissions (GAZ-3302 “Gazel”); 8 — the riser (pipe 50×35, 2); 9 — podgotovka beam (tube 60 x 45); 10 — intermediate crossmember (steel strip 100×5); 11 — rear console mounting body (tube 50×35, 2); 12 — bracket and the axis of the earring of a rear spring (GAZ-3302 “Gazelle”); 13 — longitudinal (pipe 130x45x4, 2); 14 — rear cross member (steel strip 100×5); 15 — amp rear bumper (channel № 10); 16 — brace (channel No. 8, 2 PCs); 17 — mounting bracket of a rear spring (GAZ-3302 “Gazelle”, 2); 18 — rear bumper (channel No. 15); 19 — buffer (strip steel 150×3, 2 PCs.)

In addition to the consoles to the frame is welded or bolted parts and components for Assembly of the front and rear suspensions (springs, dampers), as well as powertrain and transmission.

The seven-seater a two-volumetric body “zipovskoy” form consists of a steel supporting frame and fiberglass paneling.

Power space frame body is welded mainly of steel square tube section 45×45 mm with a wall thickness of 2 mm. And only the transverse beam consists of a steel rectangular tube section 100×60 and a wall thickness of 3 mm.

Although the frame was not calculated, however, as shown by operating experience, it is able to withstand considerable torsional and bending moments when riding with a full load on rough terrain. Perhaps the main role in its design is the quality of the welds. The craft of the welder I have mastered on his own a little earlier and even produced a transformer with toroidal core for welding machine.

In the most crucial, in my opinion, the joints are strengthened by braces, caps, or scarves — where that was possible and appropriate. This framework allows you to carry on with krasivom the trunk up to 100 kg of cargo.

The paneling of the car body vykleili of fiberglass epoxy binder separate panels. As the matrices used sheets of Finnish plywood; so they did not warp, laid on a thick layer of sand.

Panels body parts the majority of simple flat shapes. In order to strengthen them (and to some extent for decoration) provided a stiffener of rectangular and triangular shape; they formed in the manufacture of panels, attaching to the matrix planed a piece of wood, Board or dural area.

Body panels connected to the frame and to each other using fiberglass on epoxy glue. The exterior seams were sealed with epoxy putty and carefully sanded. Followed by priming and painting with fast drying air-nitroenamels.

Body shell

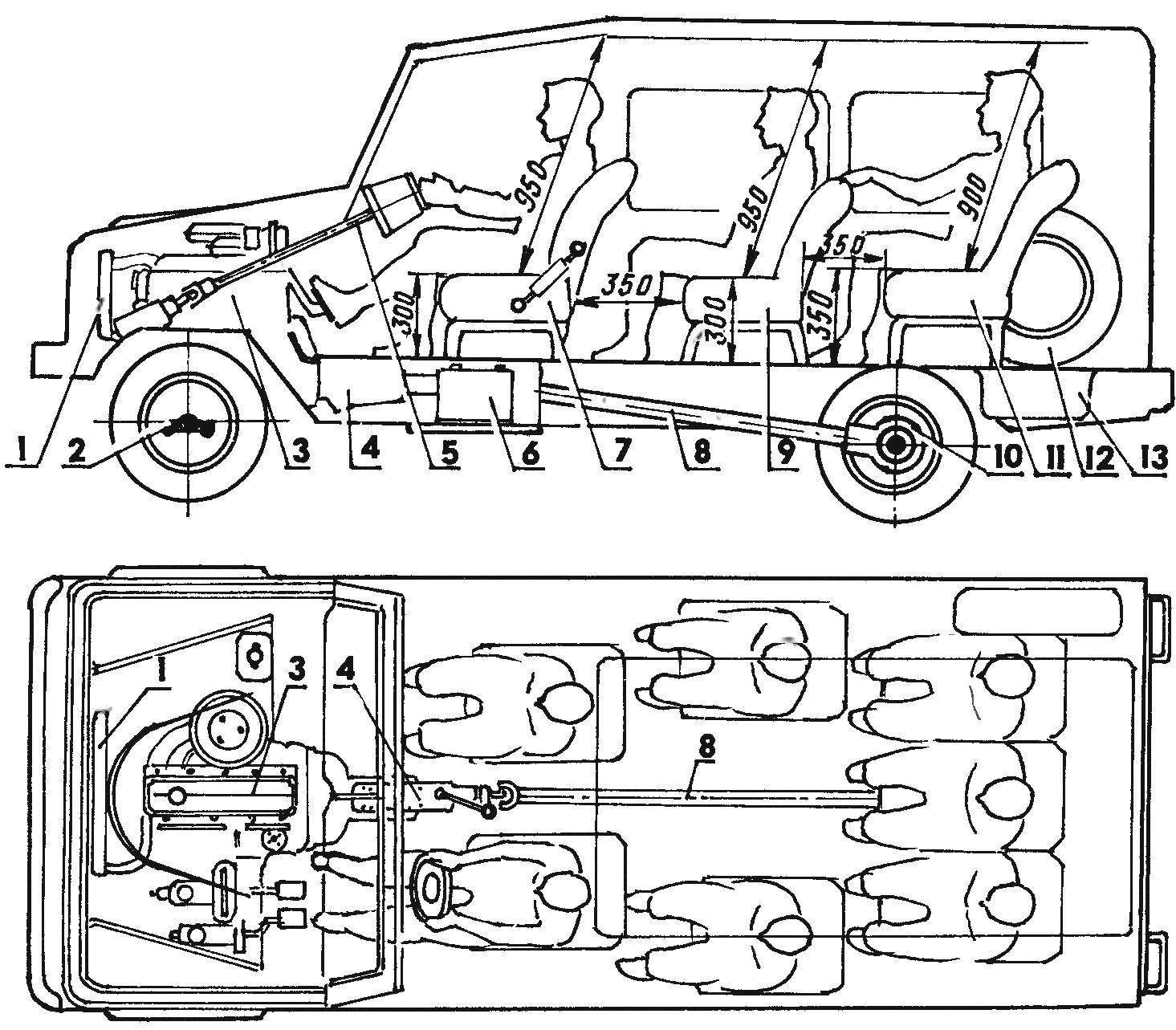

The layout of the car and the location of the seats in the cabin:

1 — radiator (GAZ-3302); 2 — front axle (from the UAZ-451); 3 engine (GAZ-24-10, 402-th model); 4 — clutch and transmission (GAZ-3302); 5 — steering (GAZ-3302); 6 — battery; 7 — the front seat (from the RAF, 2); 8 — propeller shaft (GAZ-24-10, short); 9 — the middle seat passenger (from the VAZ-2101 2 PCs); 10 — rear axle (from GAZ-24-10); 11 —back seat (from the VAZ-2101, 3). 12 — the wheel (from the GAZ-21, 5 pieces); 13 — fuel tank

In 1992 in a vacant lot outside the fleet conducted sea trials of the vehicle, eliminated the identified deficiencies. In particular, the attachment of springs from under the beams in front and rear axle was moved to the beam — in this case, improved flotation machine and she became taller and more impressive.

Front suspension: longitudinal semi-elliptic leaf springs (back from the “Moskvich-412”). Rear suspension: longitudinal semi-elliptic leaf springs (from the back “Gazelle” GAZ-3302). Brakes: the working drum, drive hydraulic, separate, with emergency alarm, vacuum booster; Parking to the rear wheels, mechanically operated

The legalization of the car, oddly enough (the stories of the craftsmen is the most difficult stage in creating a homemade machinery), major difficulties have not caused. At least red tape, nobody repaired: quickly gathered all the necessary documents, registered the car and received the state license plates. Also I advise you to watch videos of trucks in mud.

After registration, operated the car in a fairly hard mode. It has a large volume of goods necessary for the construction of cottages, sometimes overloading the machine so that the leaf springs curved in the opposite direction.

The General public, the car was shown in 1997 during the run of improvised machines. Then participated in many festivals “SamAvto” always udostaivalasj awards and prizes.

Friends and acquaintances claim that my car is similar to the German SUV “Gelendvagen”, though earlier about this I did not know. Nevertheless, they gave me the signature Mercedes grille, which I installed instead of the previously standing homemade.

Long the car was without a title — he had only an alphanumeric designation. VK-2, which was glossed as Mr mosquito 2 (the number “two” means the second self-made machine; the first, as already mentioned, was restored to “Moskvich-401”). But the family Council decided to give it a name — his name. He has been also a member of the family — no big deal without it will not.

Technical characteristics of the car “mosquito”

Body…………………………………..three-door

The number of seats……………………………………………7

Machine length, mm………………………….4220

Width, mm……………………………………. 1680

Height, mm……………………………………… 1800

The front track of wheels, mm ……………….1442

rear wheels, mm………………………….. 1420

Ground clearance, mm………………………220

Base, mm…………………………………………..2600

The corners of the overhang, hail, front axle………..47°

rear axle……………………………………..25°

Minimum turning radius

along the axis of the front wheel track, m…….5,4

Own vehicle weight, kg….. 1082

Weight of passengers and cargo, kg……………550

Full weight, kg…………………………….. 1632

The load on the front axle, kgf…………815

The load on the rear axle, kgf……………..817

Engine………………………………….ZMZ-402

Front axle……………………………UAZ-451

Rear axle……………………………..GAZ-3302

Gear shift ……. GAZ-24-10

Steering gear worm globally with trangressive roller

(gear ratio)…………………….19,1

The size of the wheels………………………………..7,35-15

Wheel size axle

off-road………………………….6,40-15

Maximum power, HP………………75

V. KOMAR