Maximum simplicity, minimum weight and dimensions at optimum amenities available materials, components and assemblies, simplified (not at the expense of quality) manufacturing technology – all this formed the basis for the design of the car, which was later called “Yauza”.

Maximum simplicity, minimum weight and dimensions at optimum amenities available materials, components and assemblies, simplified (not at the expense of quality) manufacturing technology – all this formed the basis for the design of the car, which was later called “Yauza”.

Easy and hard car body is assembled from cheap and durable material – wooden beams and hardboard; frame – tubular steel; power plant – on the basis of two-cylinder two-stroke engine of IZH-Ю5 working volume of 350 cm3 capacity, 24 HP, However, is probably more to acquaint readers with its unique design, this miniature city car.

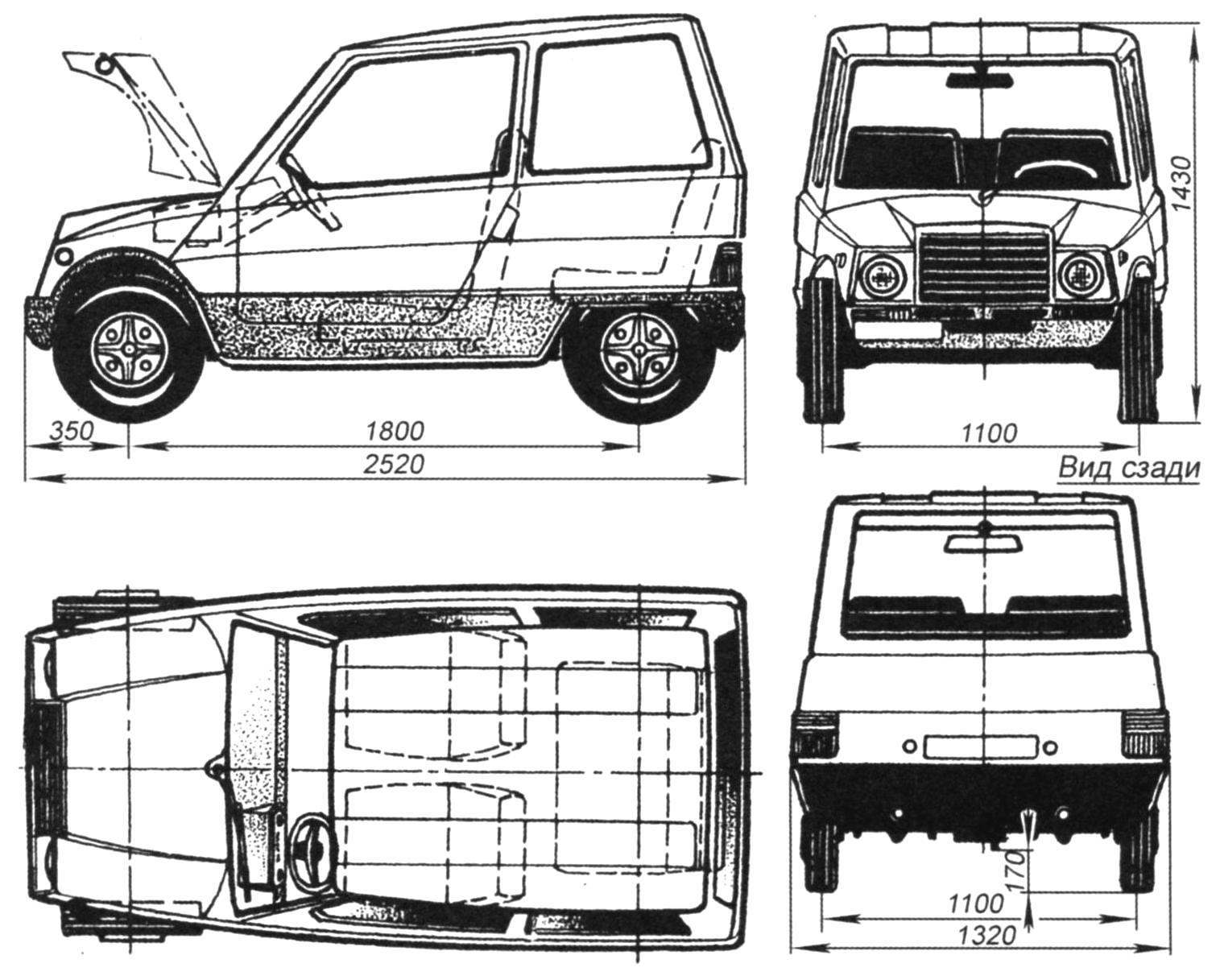

“Yauza” – a two-door front-wheel drive four-seater (2+2) passenger car.

Front-wheel drive, somewhat unusual for self-made cars, has proved very successful for this type of machine. Here, more intensive cooling is located at the front of the engine, and rational use of internal volume of the car, and a more robust engine management system with short cables and push-pull rods instead of a long and unreliable cables motorcycle type. And the maneuverability of the cars with front-wheel drive is slightly higher than that of the leading vehicles with the rear wheels.

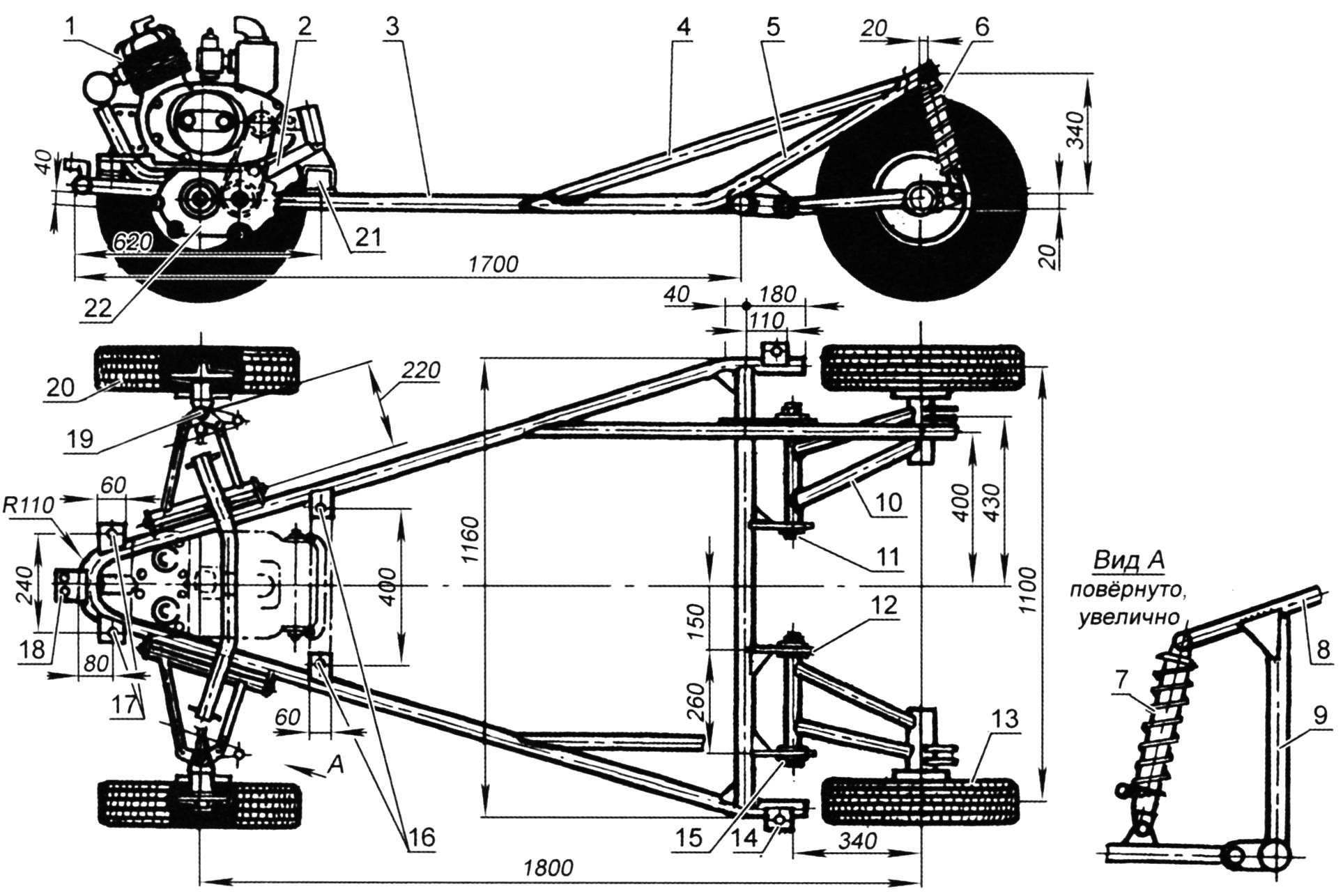

Frame minicar – flat, tubular, welded. Its basis is the power “triangle” of tubes 42×3 mm in diameter, which is fixed to the rocking of the suspension front and rear wheels. The joints of steel elements strengthened the gusset thickness of 2 mm.

Rear axle – hollow rocker arm and motorcycle shock absorbers. Each arm of the rear suspension welded tubular blanks. It should be noted that during the installation of the rear axle must be taken that the axis of the rocking chairs were on one line. For this pre-prepared brackets must be mounted on a flat steel rod or pipe and primatyvajutsja to the transverse element of the frame welding 3-4 points each. If there will be any significant distortions (that is the technological core quite easily removed from the holes in the brackets), the joints are welded completely.

Subcompact urban vehicle type “2+2” “Yauza” (front-wheel drive, two-door, with timber-framed bodywork and orgalitovoj lining, with steel tubular frame and engine class 350 cm3)

The frame of the car “Yauza” (complete):

1 – the engine of IZH-Ю5 power 24 HP; 2 – under engine frame (the old frame of the motorcycle IZH); 3 – frame (steel pipe Ø42×3); 4, 5 – bearing rear shock absorber (tube Ø42×3 and 30×2); 6 – rear shock (from a motorcycle IZH); 7 – front shock absorber (motorcycle IZH); 8,9 – bearing front shock absorbers (pipe Ø36×3); 10 – the lever of the rear suspension; 11 – lever axle rear suspension; 12 – inner bracket arm; 13 – rear wheel (sidecar С3Д); 14 – rear docking support body; 15 – outer bracket of the suspension arm; 16 – a back support sub-frame (steel strip 60×5); 17 – front support sub-frame (steel strip 60×5); 18 – a connecting the front support body and the frame (steel strip s5); 19 – axle with nut and cotter pin steering knuckle; 20 – front wheel (sidecar С3Д); 21 – a rubber pillow; 22 – main gear (motorized С3Д)

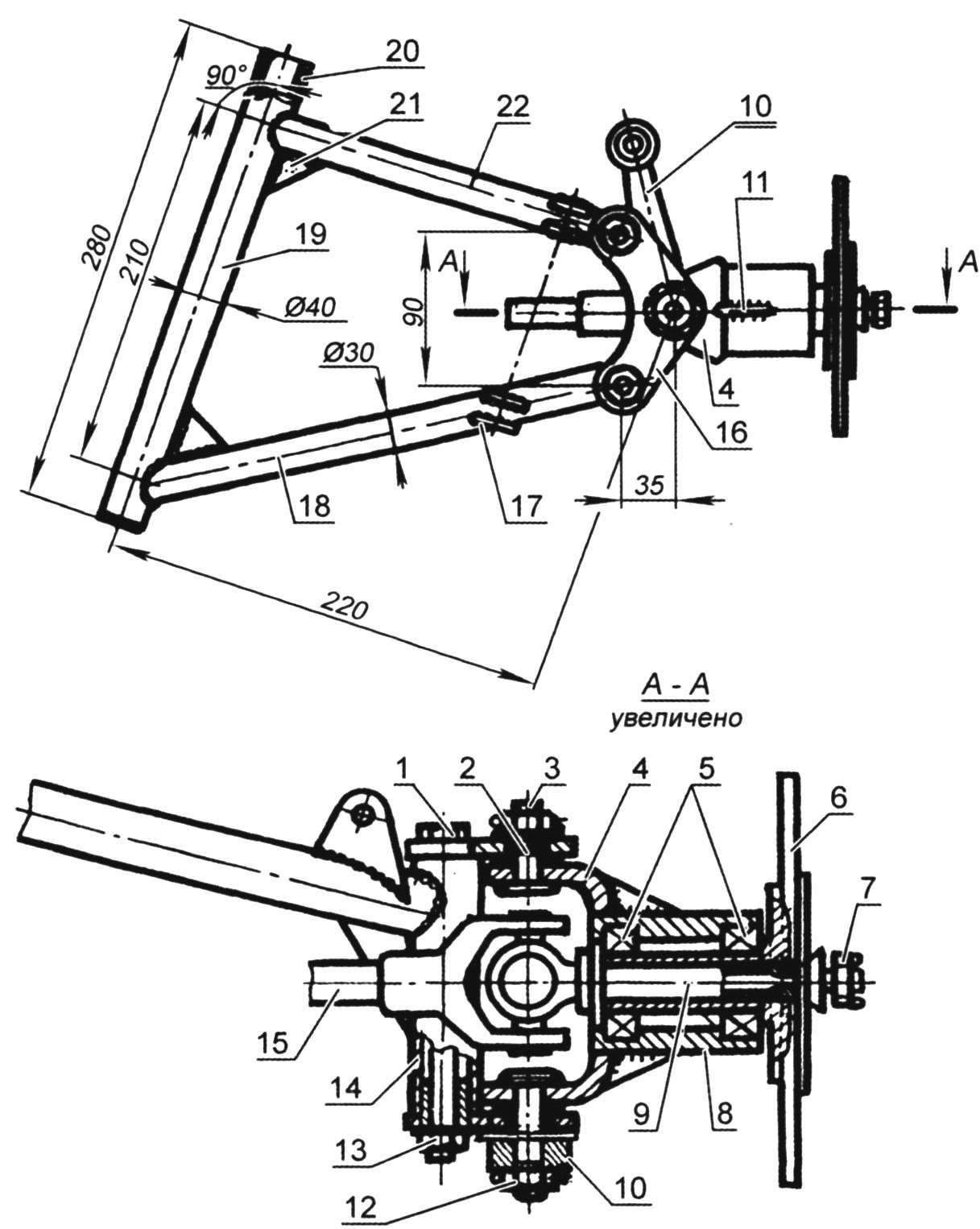

The front axle is of little micro-car also homemade. It is a device with independent suspension on semi-trailing arm and the shock absorbers from the rear wheel of a motorbike. Each arm is collected using the welding of pipes with a diameter of 30 mm and 40 mm and a wall thickness of 2.5…3 mm. Welding of the workpiece best on the simplest slipway, which must be clearly fixed to the bearing housing arm and rocking the steering knuckle. The latter is set so as to ensure the collapse of 3…4° (at a horizontal position of axis of arm) and the tilt axis of the king pin knuckle 5°. The front wheels are not perpendicular to the road plane, and inclined at an angle of 3…4° to the vertical, which reduces the torque necessary to rotate the axle around the kingpin. The tilt of the king pin steering knuckle greatly improves speed stability after the cessation of the impact on the steering wheel, the latter easily returns to its original (neutral) position. The housing of the swinging arm and fist are equipped with sliding bearings – speed Teflon or bronze bushings.

Front axle “Yauza” is designed for wheels from motorized С3Д with advanced on 50 mm rims. The hubs use roller bearings 7205К. As constant velocity joints of front wheel drive used the d-pad from the steering mechanism of the vehicle ZIL-130. Steering blocks represent modified pedal cranks road bike. Front suspension is by four motorcycle (“Izhevsk”) shock absorbers. In principle, suitable for the elastic suspension elements and other motorcycles and motorcycle from the side of the trailer.

Engine mini cars equipped, like all two-stroke motorcycle powertrain, clutch, four-speed gearbox and alternator. In addition, for the operation of the engine necessary electronic rectifier-type regulator BPV 14-10, a pair of ignition coils and motorcycle 12-volt battery.

The engine is mounted on a special frame – frame part of the old “Jupiter”, welded to two steel channels with a height of about 70 mm. To the sub-frame the engine is mounted the standard bolts and the subframe with rubber cushions to the reference sites, cut from steel sheet with a thickness of 5 mm and welded to the tubes of the frame. To the sub-frame is also welded to the cheeks of steel sheet with a thickness of 3 mm, designed for mounting main gear (reverse gear) from motorized С3Д. The propeller shafts are connected with the main transmission regular “Motoko-LastName” hinges, and with the axes of the front wheels – joints from the steering shaft ZIL-130.

Steering – rack type, from motorized С3Д. Transverse thrust split, closed by means of a steering arm-triangle.

The body of the car – with a wooden frame and a covering of hardboard. Work on the production of the body starts with a drawing on a sheet of plywood Plaza in 1:1 scale. Further along the Plaza cut blanks for frames and stringers. The Central frame is glued of five wooden bars and is reinforced inside with plywood gussets.

Front wheel location / suspension:

1 – a bolt of fastening of the bridge; 2 – the axis of the steering knuckle; 3, 12 – nuts and cotter pins the axes of the steering knuckle; 4 – wheel bearing housing (steel band E5); 5 – bearings 7205К; 6 – front wheel hub; 7 – nut M 16×1,5; 8 – bearing housing; 9 – axle; 10 – the lever of a steering trapeze; 11 – reinforcing the gusset plate; 13 – a nut of fastening of the bridge; 14 -; 15 – propeller shaft front wheel drive; 16 – bridge; 17 – suspension forks front suspension; 18, 22 – wishbone front suspension; 19 – bearing housing of the front control arm; 20 – Bush; 21 – solitaire

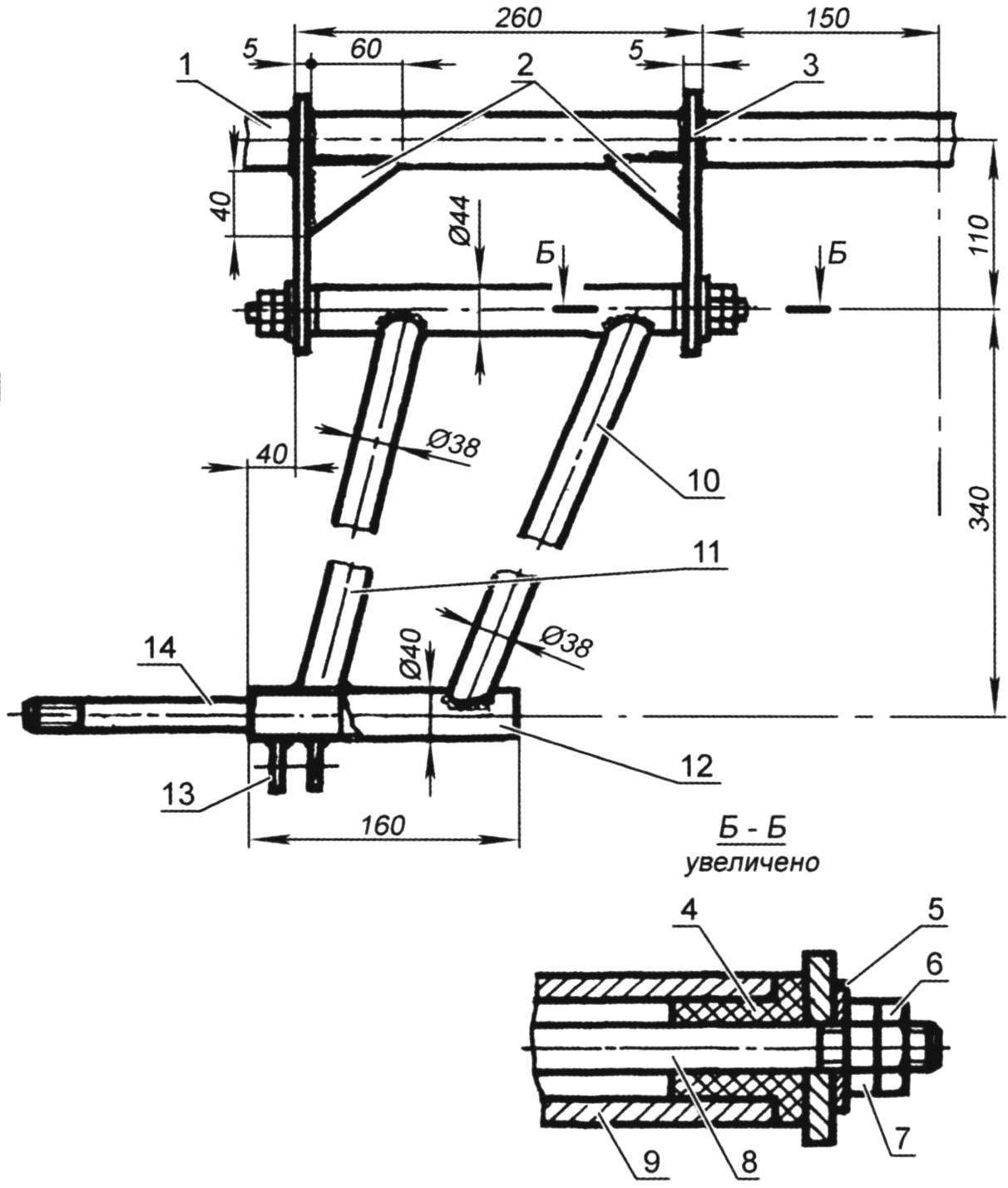

The rear suspension of the car:

1 – rear tube frame car; 2 – gusset plate (steel strip s3); 3 – bracket of the control arm (sheet s5); 4 – slide bearing lever (PTFE sleeve); 5 – washer; 6 – locknut; 7 – nut; 8 – the axis of the arm (stud М16х 1,5); 9 – cross member control arm (steel pipe Ø44×2,5); 10,11 – longitudinal elements of a lever (steel pipe Ø38×3); 12 – the case of the rear axle (steel pipe Ø40); 13 – fork rear shock absorber; 14 – rear axle shaft

The door frame is also wood. The glass doors tight and do not fall, however, the glass plexiglass is cut a round window with cover of the same material.

Body panels formed by the surfaces of single curvature, but thanks to the striking shape of the case of “Yauza” does not seem simplistic, primitive. The fact that the roof, sides and hood lined with sheets of hardboard, which are connected to the frame so that the impression of a single surface with the punch. Each of the shell elements is a ruled surface, but the whole panel has the form of a shell with double curvature.

How can I install such a casing, it is easy to understand, for example, forming the roof. To start with two strips of hardboard stuck zone “punch”. Next, cut the blank forming the upstream surface, and carefully fit to the frame. Especially pay attention to the fit of the joints with strips of hardboard. The bracket cover small screws and epoxy glue. Also mounted on canvas and in the Central zone of the roof. At the junction of strips of plating with epoxy putty is the fillet – the fillet.

Before a covering of the sidewalls of the frames of the doors are temporarily fixed in the openings by clamps or screws and are sheathed together with the sidewalls. After curing of the resin hardboard between the door frame and the door frame is cut from the inside with a hacksaw, fine teeth. Together with body is sheathed with hardboard and frame of the folding hood of the alligator type, and then in the same way as doors, cut off from the body.

Ready body puttied, processed cloth and glued fiberglass in the epoxy resin. Then its surface is sanded, primed and painted with synthetic enamel in three to four passes with intermediate grinding and Vykurovanie.

Inside the body is glued with strips of packing or construction foam, which greatly reduces the noise level in the cabin. The foam is aligned to the height of the stringers, after which it is glued to faux leather. The inner surface of the door is also filled with foam, top stitched laminate and faux leather.

As the instrument panel it is best to use the power of the IZH motorcycle-Ю4, ignition, speedometer and indicator lights “neutral” transmission, turn signal, ignition and headlight. The mounting block is easy to produce in a convenient for the driver area on the panel.

Driver seat, passenger, and rear (children) sofa – homemade. All – lightweight tubular frames are made of duralumin tubes with a diameter of 22 mm, nylon covered cord, on top of which is glued to the foam. All seats trimmed upholstery fabrics.

A few words about the car controls. As you know, a motorcycle engine (including Il-Ю5) has a kick starter, foot switch gear box and the control cables throttle of the carburettor and fuel corrector and linkage mechanism. All this had to be converted into inherent cars combination of pedals and levers.

The clutch – with a hard thrust and additional l-shaped lever pivotally mounted on the left crankcase cover. Pedal clutch control is located under the left foot of the driver.

Under your right foot – pedal “gas” (accelerator), which is a short rope in budenovskoy shell is connected with the throttle valve of the carburetor.

To the right of the steering column under the instrument panel – shift knob gear box connected to the rod with cut and modified the standard pedal to the engine. It only moves back and forth from “neutral” ahead turns on the first transmission; the consequent movement of lever back include second, third and fourth gear. To the right of the driver’s seat is a lever of switching reverse, also with a hard thrust connects to the lever on reverse gear.

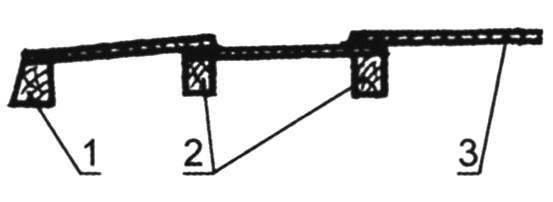

The scheme of covering the roof body:

1 is a longitudinal side roof elements; 2 – the stringers of a roof; 3 – a lining of strips of hardboard

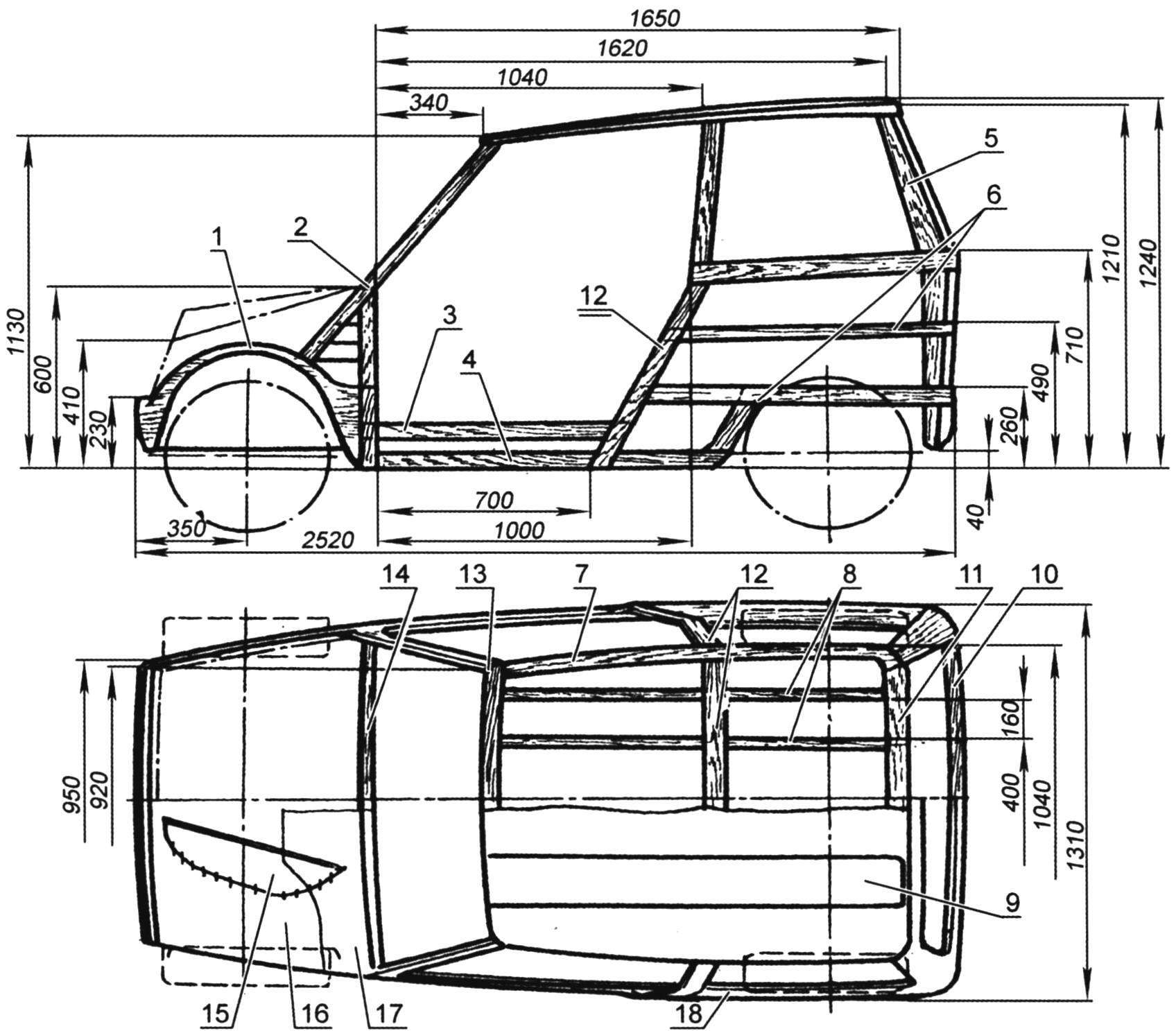

The body of the car “Yauza”:

1 – the elements of the frame of the wheel housing (plywood s20); 2, 13, 14 – elements of the front frame (wooden slats s25); 3 – nut (rake 25×40); 4 – underbody (bar 40×40); 5,11 – elements of the rear bulkhead (wooden slats s25); 6 – longitudinal set of a body (the wooden slats s26); 7 – longitudinal side roof elements (Reiki 25×40); 8 – stringers of the roof (Reiki s25); 9 – roof (strips of hardboard s4…5); 10 – cross the back of the body (Reiki s25, 3). 12 Central frame (wikiepedia of slats 30×40 and plywood); 15,16,17 – trim, wheel arch and matousek (plywood s6…8); 18 – a lining of the sides and rear of the body (hardboard s4…5)

Engine shall be a kickstarter, but instead of the regular pedals on the shaft of the starting device fixed steel pulley with two turns of nylon cord. The end of the wire is brought under the instrument panel textolite and fixed on the handle. Motor starting is a sharp jerk of the arm, after which she enjoys a return spring trigger device under the dashboard.

Interior floor is made of plywood 12 mm thick, double-coated with varnish of the type “Teks”. By the way, the same is processed from the inside, all wood and ergalieva of the body.

And the last one. Engine cooling inputs to directly affect is exactly the same as on the motorcycle, the counter flow of air, especially hot are the cylinders directly behind the intake grille. Indeed, during the movement of the motor does not overheat, however, in the absence of airflow (for example, the long stops at traffic lights, in traffic jams, with a strong tail wind) the temperature quickly rises and there is a danger of jamming of the pistons in the cylinders. To avoid this, in the engine compartment installed electric power of about 20 watts from “the Zhiguli” heater, which is enough in critical situations to provide cooling.

Worth mentioning about interesting engine modifications IZH-Ю5 – motor with liquid cooling. This motor is perfectly suited for automodular as greatly to normalize its temperature regime is quite easily installed in a convenient location of the radiator and electric fan.

Technical characteristics of the car “Yauza”

Overall dimensions, mm:

length…………………………………………………….2520

width………………………………………………….1320

height…………………………………………………..1430

Base, mm………………………………………………..1800

Track, mm………………………………………………1100

Ground clearance, mm…………………………………………..170

Lots of little micro-car, kg:

dry………………………………………………………400

full……………………………………………………620

Maximum speed, km/h…..80

Engine……………………………………………….IZH-Ю5

Engine power, HP…………………………24

Fuel tank capacity, l…………………….18

I. EVSTRATOV