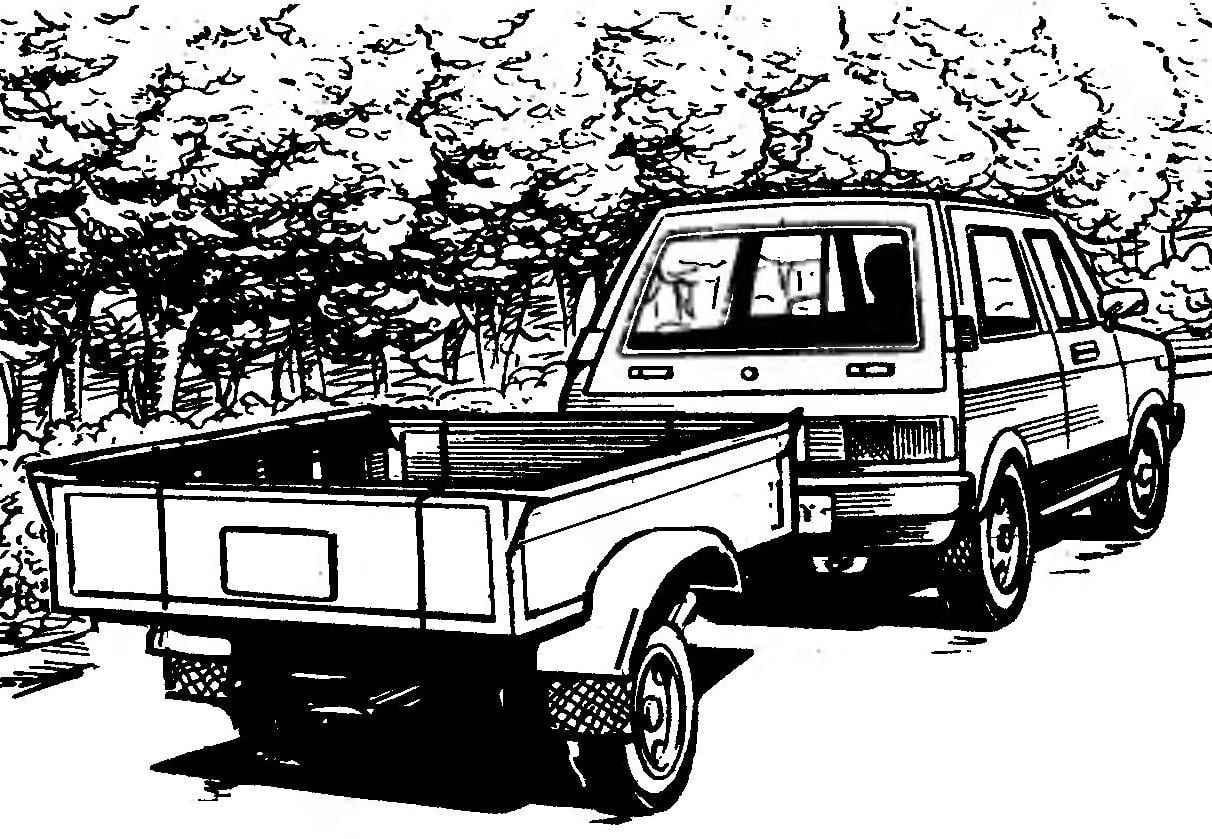

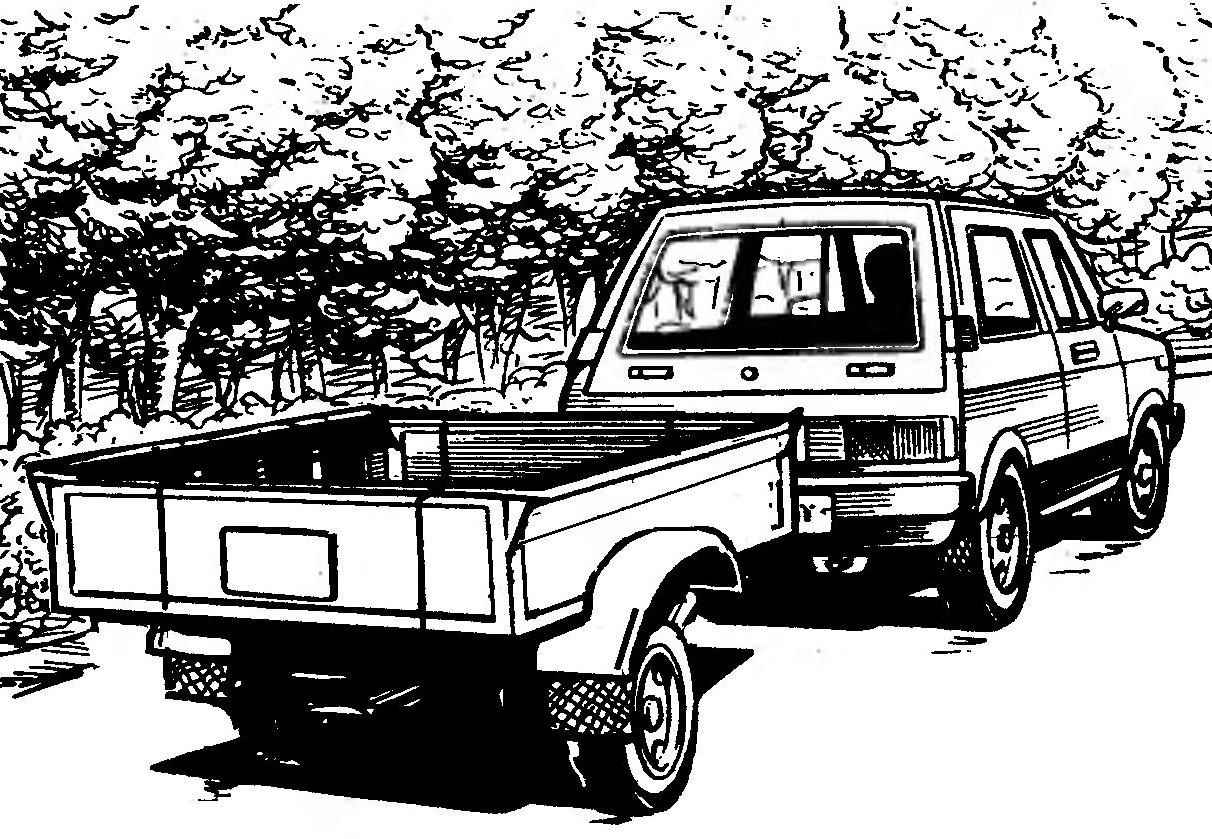

Outset: the design of the trailer is simplified — it has no brakes and signal lights. Therefore, for transportation on public roads without equipping the above devices the trailer it cannot be operated.

The trailer is a single axle, two-wheeled, folding the front and rear sides.

The body has its own frame and is self-supporting design. Mounted on a beam bridge is a rigid longitudinal struts and transverse rods. Of course, it would be possible to arrive easier: to weld the shaft directly to the middle of the beam, and to the resulting T-frame to attach frame body. But this arrangement would have deprived the opportunity or significantly complicate future upgrades of the trailer (if necessary equipment its soft suspension). Under the current structure this option rework to implement quite easily by replacing the longitudinal struts on the springs and the transverse struts — shock absorbers.

Damping of shocks, jolts and vibrations from road irregularities is accomplished by the pneumatic wheels rubber bushings and silent blocks in the struts. Moreover, the larger the weight, the softer is the trailer.

The base of the bodyshell: two longitudinal members and five cross beams on them. Such a relatively large number of them is dictated by the ensure the rigidity of the floor of the body. For the same reason, stands on the longitudinal sides of the body — also in five.

The trailer increased carrying capacity:

1 — locking device; 2 — bracket support legs and safety chain; 3 — pole (dural tube d80x3); 4 — clip retaining the support leg in the transport position (spring steel, strip 10×2); 5 — ladder M8 with washers and nuts (STZ, rod d8, 8 sets.); 6 — a hinge pivoting boards (8 pieces); 7 — striker bar (Board 90×30); 8 — inclined arc of the tent (duralumin pipe d19x1,5, 2); 9 — video arc tent (duralumin pipe d19x1,5, 4 pieces); 10 — tent (waterproof fabric or a tarp); 11 — wall side walls (made of anodized aluminum, the sheet s is 1.5, 2); 12 — rope fastening of an awning to the body (d10); 13 — hook lead rope (STZ, sheet B1,5, 20); 14 — fastening ring (plate s1,5, 20); 15 — safety chain; 16 – folding stand (square pipe 25×25); 17 — longitudinal (roll-formed channel 45×45, aluminum sheet s2, 2); 18 — wing (aluminum, sheet s1,5, 2); 19 — the wheel (from the car “Moskvich” or “Zhiguli”, 2); 20 — brace (steel pipe d30x2, 4 PCs.); 21 — cross beam of the body frame (roll-formed channel 50×20, aluminum sheet s, 12 PCs); 22 — the outer covering of the front (and rear) side (duralumin, sheet s1); 23 — medium solitaire frame drop side (STZ, sheet s1,5 PCs 4); 24 — frame stand side (square pipe 20×20, 6 PCs); 25 — rail frame with front (and rear) side (square tube 20×20); 26 — extreme solitaire frame drop side (STZ, sheet s1,5, 8 PCs); 27 — the body of the strut (U-shaped profile 66×42 flare (b = 15, duralumin, sheet s1.5, 6). 28 — body wheel housing strut (aluminum, sheet s1,5, 4 pieces); 29 — hub (steel 30KHGSA, circle d62, 2); 30 — the hub flange (steel 30HGSA, leaf s20); 31 — kremowy bracket mounting struts to the beam; a 32 — beam bridge (steel pipe d50x3); 33 — lateral thrust (steel pipe d30x2, 2); 34 — splash guard (rubber, sheet s5, 2 PCs.); 35 — niche insert (aluminum, sheet s1,5, 2); 36 — floor (duralumin, sheet s1,5); 37 — bracket-wing (aluminum, sheet s1,5, 2); 38 — bushing striker bar (place)

The side members and cross beam are curved duralumin sheet thickness of 3 mm in the form of a steel channel with dimensions of 45×45, respectively, and 50×20 mm. Spars and beams fastened together with M8 bolts with spring washers. Connection of dural sheets (except the bottom) with power elements made of aluminium rivets 3 mm in diameter with a semicircular head.

Stands the sides are bent from 1.5 mm steel sheet is also U-shaped, but with flanging, which they riveted to the sides. Over wheels these racks are shortened. The sides and bottom of the body — of the 1.5-mm dural sheet. At the bottom of villacana a few ribs. The bottom is riveted to the cross beams of the frame by rivets with countersunk heads. Side walls, front and rear a little wound on the ends, giving additional rigidity to the body.

Lateral side is made with a small divergence of the walls up. Such a position provides loading of bulk materials without excessive losses. In addition, when a relatively small track (wheel must not protrude beyond the dimensions of the vehicle) managed to avoid the wheel arches inside the body. The rear Board, and front — hinged. This offloads a large part of the loose material from the trailer “truck” — due to the shift of the center of gravity of the load (the drawbar for this tractor is disengaged, and rises up). Pushing the front side of the drawbar, and the rear at 90° and securing it in this position for the stretch marks on the trailer can carry long timber, pipes, etc. the Flip side have their own frame from square tube 20×20 mm, covered outside with a sheet thickness of 1.5 mm.

The upper edge of the sides of the striker bar is installed. It is attached to the top of the wall boards. His holes are inserted arcs that serve as a support for a removable awning made of heavy waterproof fabric. The attachment of the awning to the side of the body is made using a nylon rope passed through ringed holes and acepsimas the hooks on the outside of the sides of the body.

The loading height of the trailer (distance from the ground to the bottom of the body) is relatively small — 510 mm.

A beam bridge is a steel pipe with a diameter of 50 mm and a wall thickness of 3 mm is welded at the ends of the axle for bearings 7205. On each axle there are two. Tapered bearings are selected because of the Laden trailer when driving off-road large axial load. In addition, such bearings over time, if necessary, and “pull” to adjust. The bearings are fitted in the hub welded thereto flanges for attachment of the wheels. Each flange is reinforced with four ribs welded on the inner side and to the flange and to the hub. The flange is made of two groups of threaded holes M12x1,25: four holes for mounting of disc wheels Vase and five holes, “Moskvich”. Wheels from cars of a smaller class for such a heavy trailer to take is hardly appropriate.

The connection of the beam with the body, as previously stated, hard. It is made of two identical longitudinal struts (in place of springs in conventional trailers) and cross brace (in place of the absorber) on each side. These parts are made of steel pipe 30×2 mm. the Upper ends of the struts through silent-blocks attached directly to the spars. Lower ends welded to the semicircle kremovogo bracket. Semicircles on the beam, tightening the M8 bolts, and to prevent the top from turning in the bracket placed steel strip with a tongue which is inserted into a rectangular hole in the pipe beams.

Locking device:

1 — locking (steel); 2 — bushing (steel 30KHGSA, circle d30); 3 — pin (steel 30KHGSA, circle d10); 4 — special nut М39х of 1.5 with two hard fingers (steel 30KHGSA, circle d50); 5 — coil spring; 6 — the plug (Д16АТ, circle d30); 7 — retaining ring (steel 50KHFA, sheet s1,2); 8 — locking bolt M8 (steel 30KHGSA); 9 — locknut М39х1,5 (steel 30KHGSA); 10 — connecting sleeve (steel 30KHGSA, circle d80); 11 — a bolt M8 (2 PCs); 12 — pole

Stiff suspension:

1 — body; 2 — body strut; 3 — spar; 4 — cross beam; 5 — brace; 6 — pinch bolt M8 spring washer; 7 — semiring kremovogo bracket (steel 30KHGSA); 8 — yoke rubber brace (steel 30KHGSA, steel d40x5,4x); 9 — Bush silent-block brace (rubber, 4 pieces); 10 — axis of the silent block with nut M10 and washer (6 set); 11 — retaining ring (steel 50KHFA, sheet s2, 2 PCs.); 12 — locknut M20x1,5 (2 pieces on the right side — with right-hand thread on the left — with left-hand thread); 13 — axle bearings 7205 with thread M20x1,5 (2 pieces on the right side — with right-hand thread on the left — with left-hand thread); 14 — the plug (D16T, circle 054, 2); 15 — lock washer (steel 20, sheet s2); 16 — adjusting nut M20x1,5 (2 PC right-and left-hand thread); 17 — the screw M22x1,5 mounting wheels (4 or 5 depending on model); 18 flange for mounting a wheel (steel 30HGSA, leaf s20,2); 19 — the edge flange (steel 30HGSA, leaf s5, 8 PCs — 4 PCs on disk); 20 — wheel hub (steel 30KHGSA, circle 062, 2); 21 — bearing 7205 (4 PCs — 2 PCs to the hub); 22 — the cuff (2 PCs.); 23 — the boot (STZ, sheet s2, 2); 24 — beam axle (steel 30KHGSA, rough d50x3); 25 — locking insert (45 steel, sheet s2,5, 2); 26 — connecting plug spacers (STZ, sheet s2,5, 2); 27 — adjusting bushing M20x1,5 (steel 30KHGSA, steel 020×4, 2); 28 – an adjusting nut М20х 1.5 (steel 30KHGSA, 2); 29— cheek kremovogo bracket (steel 30KHGSA, sheet s4,2 PCs bracket); 30 — sleeve retainer insert (STZ, pipe d14x2,2 PCs bracket); 31 — bushing connecting bracket spacers (STZ, pipe d16x3); 32 — lug connecting bracket spacers (STZ, sheet s6); 33 — locknut M20; 34 — strut (steel pipe); 35 — the cradle (STZ, sheet s2,5, 5). 36 — retaining boss (STZ, circle d10, 5 PCs); 37 stepladder

The lower end of the transverse strut is also attached to this terminal by means of a specially provided for this M10. The upper end of the strut through the rubber block is fixed in the bracket mounted on the middle crossbar of the frame. The spacer is made with a threaded sleeve at the bottom, which allows you to make the necessary adjustment of the thrust along the length.

The trailer hitch is made of duralumin tubes with a diameter of 80 mm and a wall thickness of 3 mm. It is secured to cross frame step ladders M8. Previously on the stepladder wearing a steel cradle under the pipe. The tool trays welded retaining lugs, and the pipe wall drilled the appropriate holes to eliminate pulling of the drawbar.

Design hitch lock needs to fit the towbar using a tractor, but in any case it is necessary to make a damping device for damping jerks and shocks transmitted from the tractor to the trailer and Vice versa. It is useful to provide it with a safety chain, and a pole — a front hinged leg.

The main advantage of the trailer is that to ship him with inert materials (sand, gravel, soil) can be as much as will fit in the back. If only the wheels survived and tractor mastered. In General, a trailer is the most that neither is a workhorse.

E. Evsikov, G. L u b e R C s, Moscow.

Recommend to read CAR? Air SUSPENSION! In the taiga edges is not easy to do without the vehicle of the increased passability. Therefore, all-terrain vehicles have always held in high esteem. For example, I ride my both summer... IN THE HALL AND IN THE FOREST For making models are used, the stems of cereals: oats, rye, barley, Timothy and reeds. The FUSELAGE consists of two parts. The first is a stalk of straw Ø 3-4 mm, the second...

Many developers will be the future homeowners or gardeners — you have to solve the issues of transportation for short distances of local construction materials such as soil, sand, stone. Some owners, having their own transportation equipment (automobile, tractor or even a walk-behind tractor), buy her a trailer. However, the price of industrial trailer such that a prudent owner, especially if he is a man of the workman, be sure to pretend to do the trailer yourself? But for these craftsmen and to the development of a cargo trailer.

Many developers will be the future homeowners or gardeners — you have to solve the issues of transportation for short distances of local construction materials such as soil, sand, stone. Some owners, having their own transportation equipment (automobile, tractor or even a walk-behind tractor), buy her a trailer. However, the price of industrial trailer such that a prudent owner, especially if he is a man of the workman, be sure to pretend to do the trailer yourself? But for these craftsmen and to the development of a cargo trailer.