It’s not often that you’ll encounter homemade snowmobile equipment for children on winter paths and hills. Mostly, these are well-known industrial designs like “Chuk and Gek”. Some have low-power internal combustion engines installed. Despite all their obvious advantages, they also have disadvantages. However, avoiding discussions about the “pros” and “cons”, let’s get acquainted with an unusual design of a sled-monoski with an electric motor.

The monoski is a light elongated body with smooth contours, in the lower part of which there is a tunnel with an electric-driven tracked running gear. The latter distinguishes this device from common snow scooters and significantly expands its capabilities. So, our sleds pull themselves up the hill.

The ski is controlled by changing the position of the driver’s center of gravity. Braking is done with the feet. At the same time, many muscle groups are engaged, which allows the machine to be classified as a sports trainer.

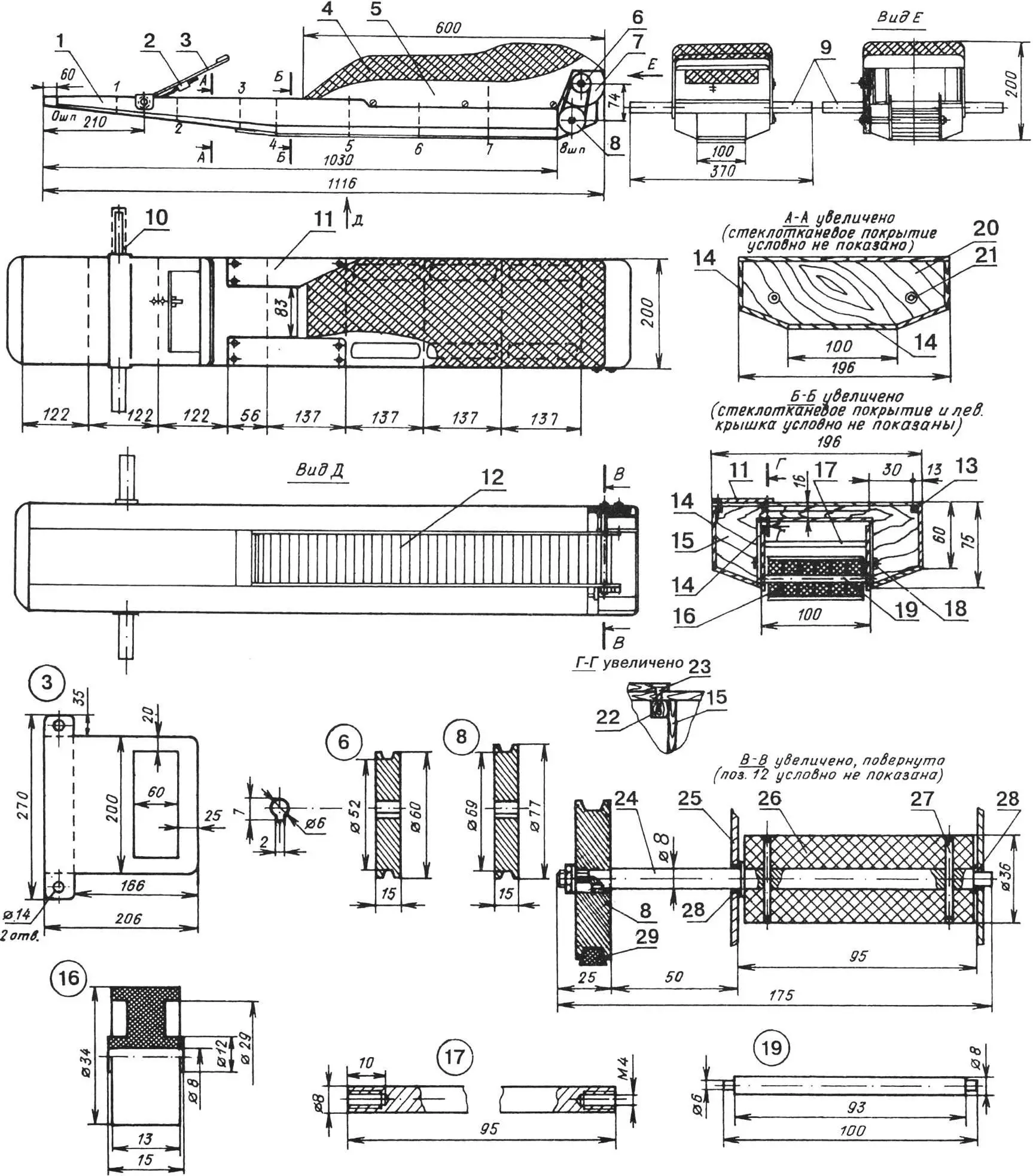

1 — body, 2 — three-position push-button mode switch for electric motor, 3 — handle (AL3, sheet s2.5), 4 — seat upholstery (foam rubber, leatherette), 5 — seat body (plywood s3), 6 — drive pulley (D16), 7 — electric motor DV1KM, 8 — driven pulley (D16), 9 — footrest shell (capron), 10 — footrest (D16, tube 14×2), 11 — cover (plywood s3), 12 — track (rubberized fabric), 13 — stringer (pine, batten 10×10), 14 — body skin elements (plywood s3), 15 — rear frame (plywood s3), 16 — support rollers (capron), 17— spacer (D16, rod Ø8), 18 — M5 bolt for fastening running gear to body (14 pcs.), 19 — support roller shaft (St3, rod Ø8), 20 — frame 3 (plywood s3), 21 — track tensioner mounting unit (M5 nut, washer), 22 — transverse beam (pine, batten 10×10), 23 — screw, 24 — drive roller shaft (St3), 25 — running gear side plate, 26 — drive roller (capron, rod Ø36), 27 — pin (St3, rod Ø3), 28 — bushings (brass), 29 — drive belt (520x10x6).

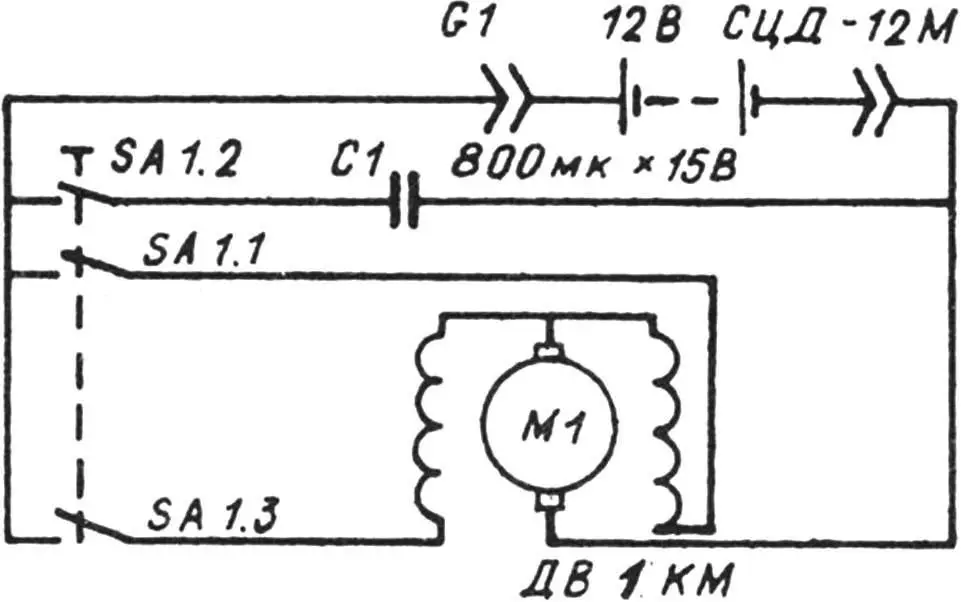

An electric motor DV1KM or similar is used as the engine. It’s even better to use an automotive starter. It, however, should be substantially modified (see “Modelist-Konstruktor” No. 4 for 1996). The power source consists of SCD-12M type storage batteries and high-capacity paper capacitors (0.5—4 F), which in idle mode (downhill descent) are recharged from the motor-generator. If quasi-molecular capacitors of large capacity are installed, the batteries will practically become unnecessary. The electrical circuit is controlled by a conventional breaker or thyristor unit.

The monoski body is made in the traditional “ship modeling” way on a building frame. Frames, up to and including the third, are made solid, and subsequent ones — with a cutout for the tunnel. The “deck” skin has technological windows intended for access inside the body during running gear installation. To prevent snow from entering, the front windows are protected by tightly fitted covers, and the rest are closed by the seat.

After assembling the body, its external and internal surfaces are covered with two to three layers of thin fiberglass cloth impregnated with epoxy resin. Holes are made in the side walls of the tunnel corresponding to the holes on the running gear side plates (middle row).

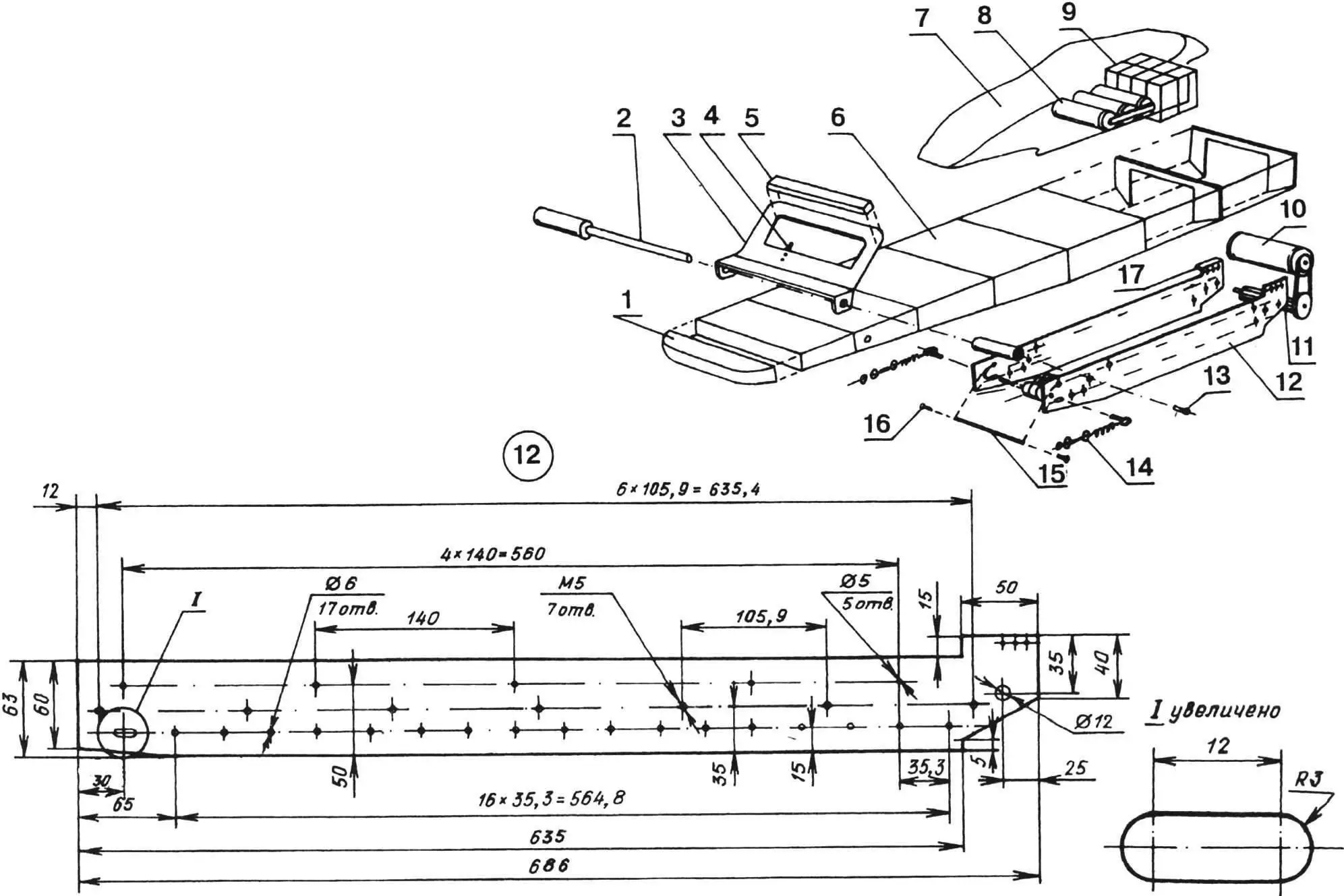

1 — bumper (rubber), 2 — footrest, 3 — handle, 4 — switch, 5 — overlay (linden, batten 25×10, L190), 6 — body, 7 — seat, 8 — capacitors, 9 — storage battery, 10 — electric motor, 11 — drive roller, 12 — side plate (D16T, sheet s2.5), 13 — M5 bolt, 14 — track tensioner, 15 — spacer, 16 — M4 screw, 17 — engine mounting bracket (D16T, angle 20x20x2.5).

The control handle (if it can be called that) is made of soft sheet aluminum and secured to the body using a footrest-tube, on the ends of which a shell is fitted (tube from a plastic hoop).

The seat is made of foam rubber and leatherette and installed on the battery compartment cover.

The running gear consists of an electric motor mounted on two metal side plates, a drive roller, support rollers, and a track. The side plates have three rows of holes: for support roller shafts (bottom row), for M5 bolts fastening the running gear to the body (middle row), and for spacer screws (top row). In addition, the rear part of the side plates contains mounting holes for the drive roller, motor, and bracket for its mounting.

The track and its ground cleats are made from rubberized fabric from a kayak. Rubber rollers from a household trainer for back and leg muscles are used as rollers, but they can be made from wood.

It’s best to start assembling the running gear by installing the drive roller with shaft between the side plates and securing the motor to them. After that, the side plates are fixed with spacers (but not completely), shafts with support rollers are inserted, and only then are the spacer screws finally tightened. When the structure has gained rigidity, the track is fitted onto the rollers, and the belt is tensioned on the pulleys. The track ends are glued and for reliability, punched with metal staples. In this form, the running gear is inserted into the body tunnel and secured with M5 bolts. The track is tensioned using a spring device on the third frame by displacing the front support roller.

After connecting the motor to the power circuit, all electrical connections are carefully insulated and covered with moisture-proof varnish.

Of course, this is one of the possible design options. We advise followers, when building a monoski, not to repeat it literally, but to creatively develop the ideas embedded in it, continuing the search for new solutions.

“Modelist-Konstruktor” No. 12’97, R. SINGATULIN