While equipping my bathroom as a sauna (see “Modelist-Konstruktor” No. 10, 1997), I decided to make a powerful (3 — 3.5 kW) and reliable heater myself. The most acceptable option seemed to me to be an electric heater in a tin bucket with an asbestos-cement terminal block and brass studs, covered with a hinged metal housing (Fig. 1). But when I plugged this heater into the socket, I smelled burning.

The cause turned out to be a poorly spring-loaded contact and loosely tightened terminals. After the elastic contacts in the socket were properly tightened with pliers, and the wire ends in each terminal clamp were thoroughly cleaned, twisted, soldered, and securely tightened with a screw, the socket practically stopped heating, although the power of the load connected to it was 3.5 kW.

The next problem was finding the optimal design for the heating element of the heater. I started experimenting.

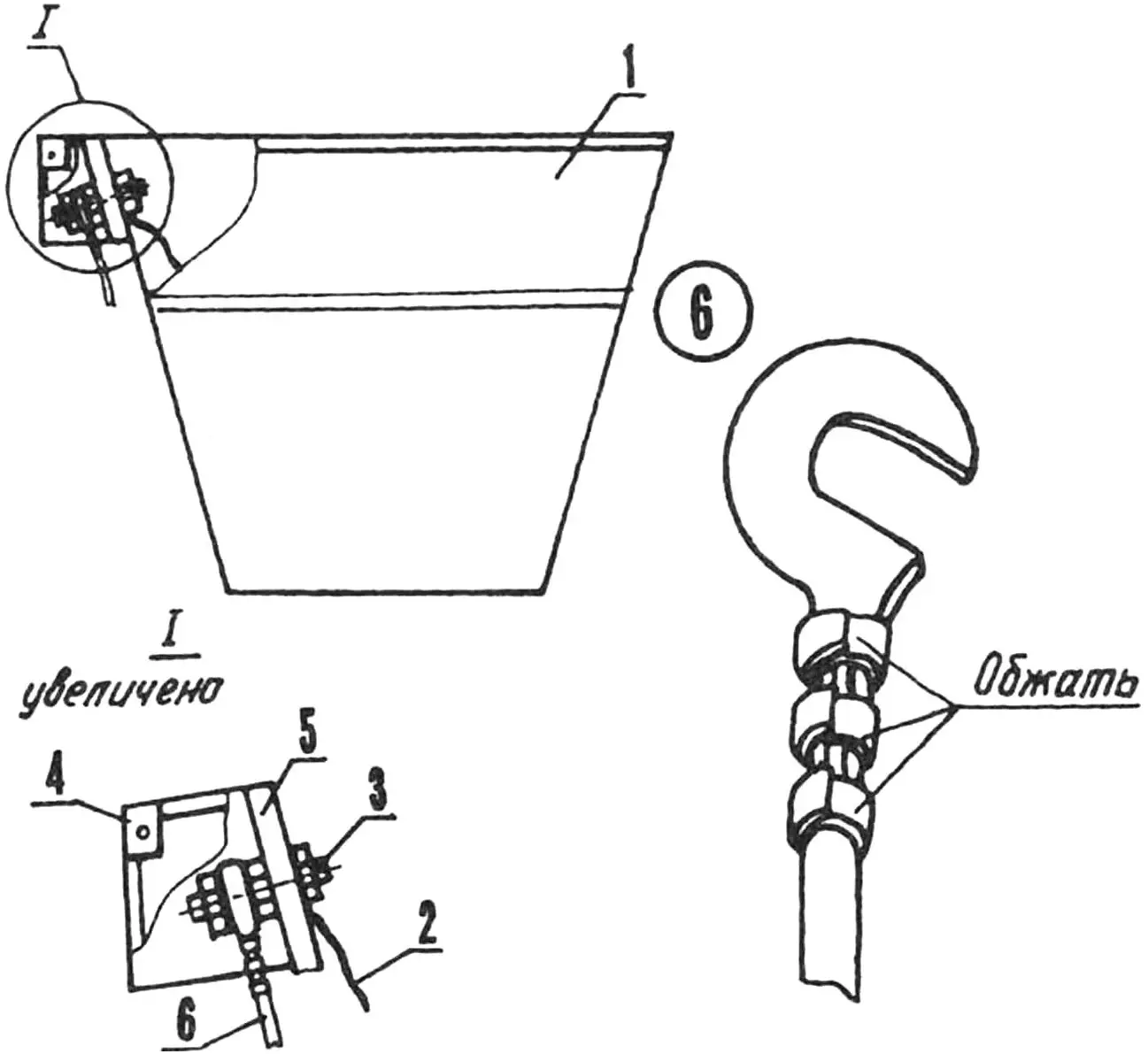

1 — bucket with stones and electric heater; 2 — wire in heat-resistant insulation (2 pcs.); 3 — M6 stud with three nuts (bronze or brass); 4 — hinged lid on axis (roofing iron); 5 — terminal block (asbestos-cement board); 6 — wire with terminal hook (2 pcs.).

First, I tried a pancake-shaped burner rated at 1.5 kW, produced by domestic industry for household electric stoves. Installed in the heater as a single unit, it managed (in 15 hours!) to heat the sauna-bathroom only to 50°C. Then I applied a combination popular among DIY enthusiasts of two combined burners connected in parallel (Fig. 2). And I realized: such a heater is not for me. First, because the strength reserve of double burners lasts only for 3 — 5 sessions. Second, making the combination takes a lot of time and effort. After all, the standard terminal blocks have to be removed, as well as the metal disks on which they are mounted. And in the standard “rib” of each burner — cut out a recess for the leads. Moreover, the heater turns out to be expensive, just the burners alone cost a lot! And that’s third.

1 — electric burner (2 pcs.); 2 — M6 nut; 3 — M6 stud; 4 — lead in ceramic bead insulation (2 pcs.).

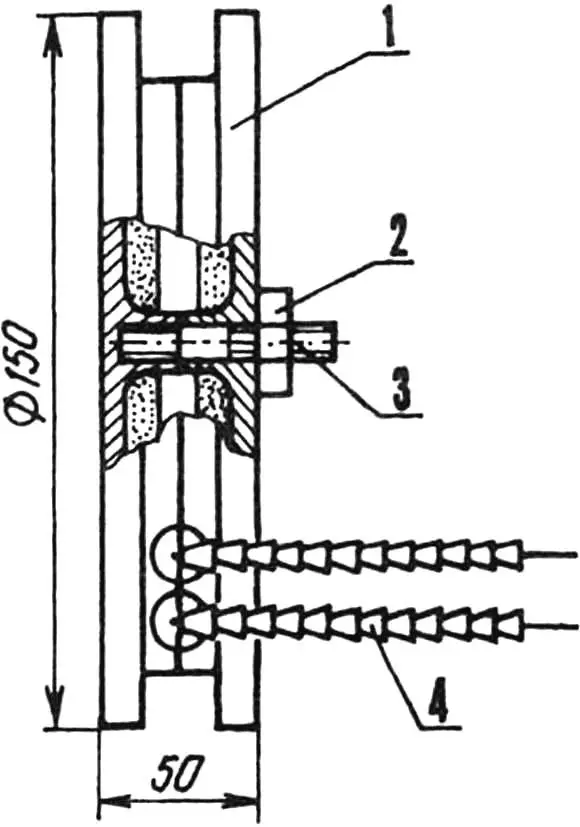

In search of a suitable and cheaper design, I also considered an option with a homemade heater inside a 150-mm section of steel pipe with a diameter of 100 mm and wall thickness of 4 mm (Fig. 3). Such a “samovar” is convenient because, by removing the lid, you can easily replace a burned-out element. The only drawback is that the housing itself burns through quickly, even from extra-thick-walled steel pipe.

1 — lead in ceramic bead insulation (2 pcs.); 2 — removable lid (St3); 3 — nichrome heater spiral (consumed power 3 kW); 4 — fireclay cup; 5 — housing (steel pipe 100×4, L146, feedthrough insulators conventionally not shown); 6 — plug (St3, sheet s4).

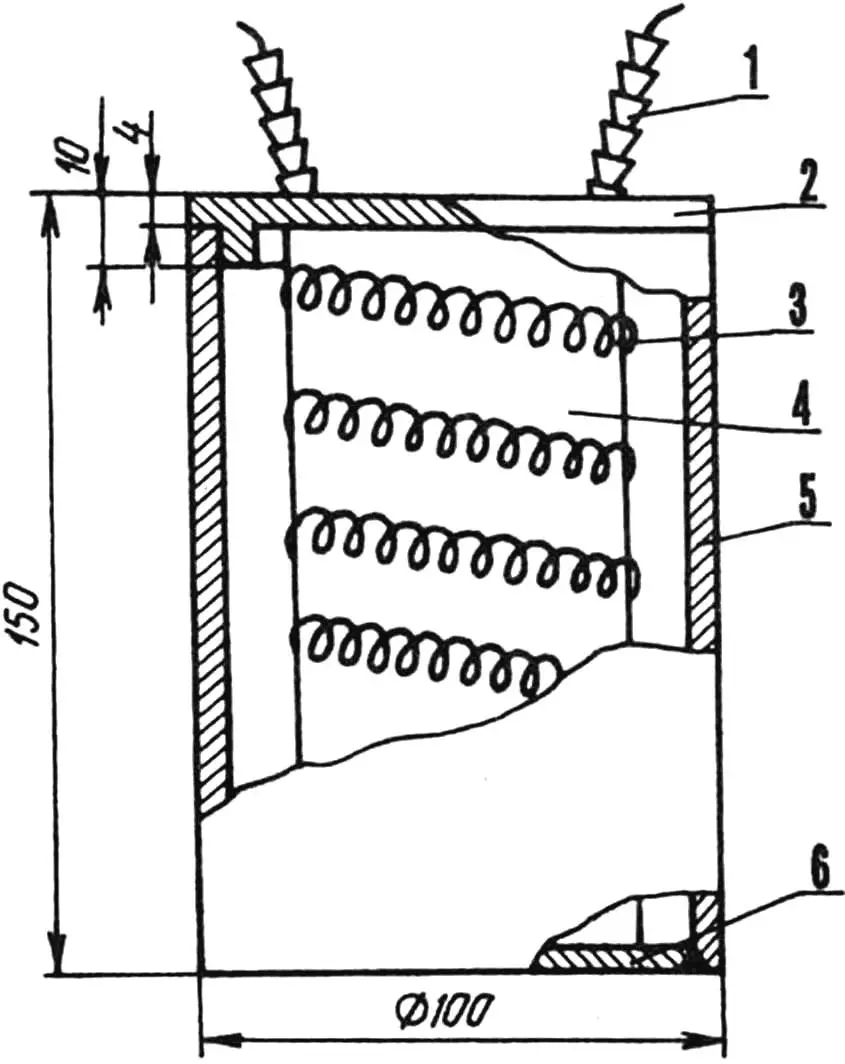

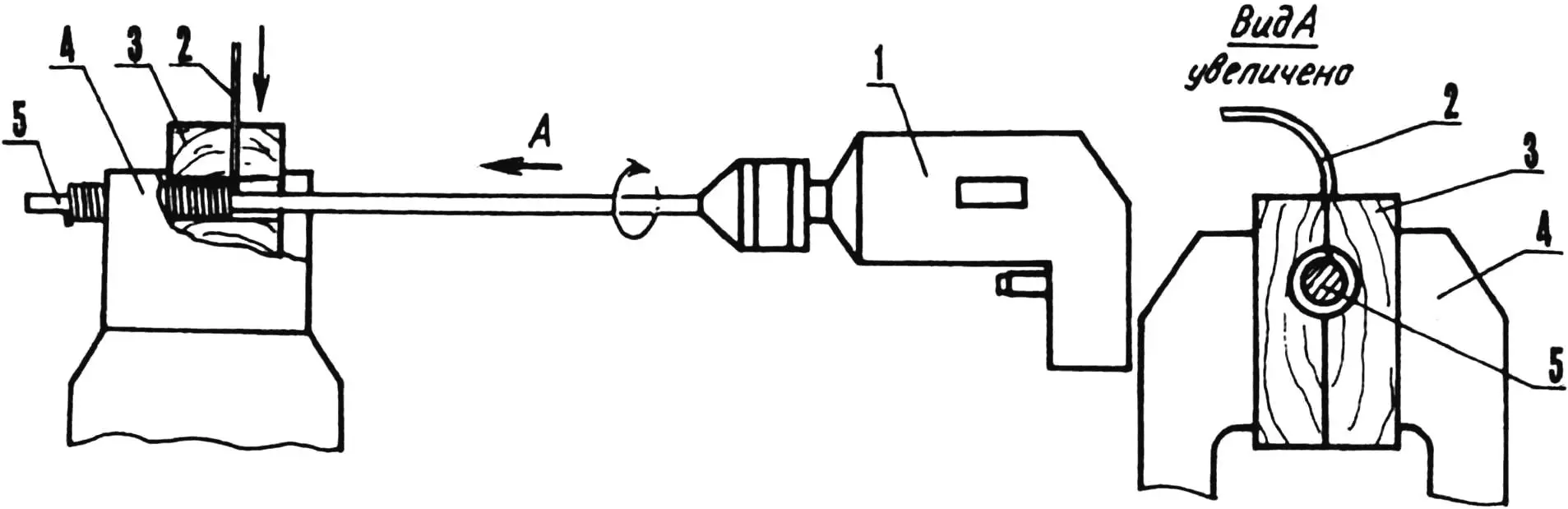

In the end, I came to the conclusion that the best heater for a sauna in the bathroom would be a spiral made of nichrome wire with a diameter of 1 mm and a length of 10 m. Moreover, I took annealed nichrome (it has a greenish tint and increased softness). I wound the spiral on a rod with a diameter of 10 mm and a length of 600 mm using an improvised machine made from an electric drill with a speed regulator (Fig. 4).

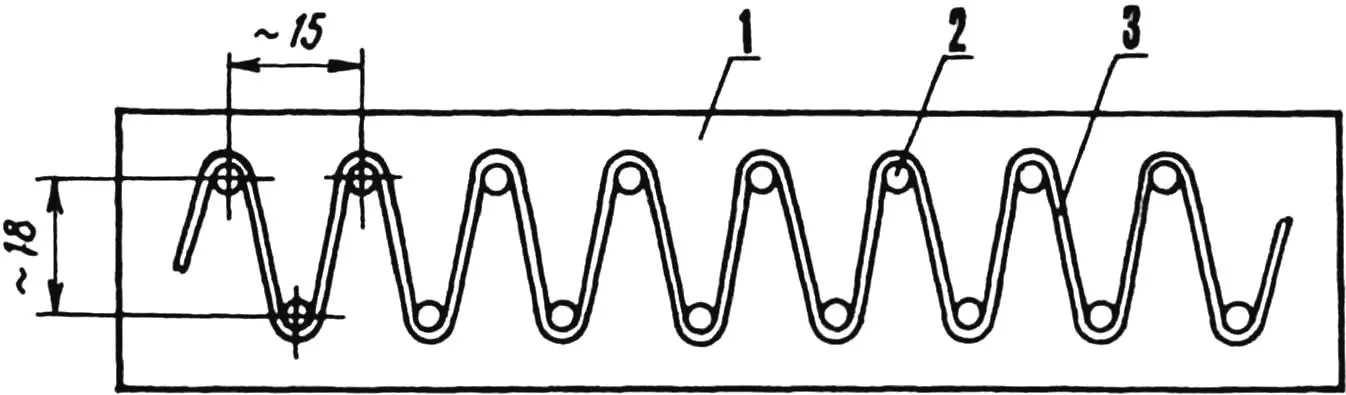

Instead of a spiral, you can make a less compact “snake”. It is made by bending nichrome wire on a simple but effective device (Fig. 5.).

I stretched the nichrome heater-spiral to a length of 3 m and evenly laid it between the stones. As practice shows, the first wire burnout occurs only after ten sessions of the most intensive operation. But this period can be extended by following one single rule: do not splash water on the heater until the spiral disconnected from the electrical network stops glowing, which takes no more than 15 minutes.

Restoring the heater’s functionality is not difficult. The technology is simplest: clean the ends of the burned-out spiral to be spliced, fold them in half and, clamping with two pliers, twist them.

1 — drill with speed regulator; 2 — nichrome (wire Ø 1); 3 — guide spacer (wooden block 100x50x20, 2 pcs.); 4 — vise jaws; 5 — mandrel (steel rod Ø 10).

After each such connection, the spiral naturally shortens. This means the heater’s power increases. For example, over 32 sauna sessions it increased (after several forced twists) to a critical value — 3.7 kW. At an electrical supply voltage of 220 V, this threatens to trip the overload protection circuit breaker (such devices, rated for a trip current of 16 A, are installed at the input to every modern apartment).

What to do in such situations? Of course, you shouldn’t give up on a home sauna. If the nichrome of the “heat generator” is still in decent condition, you can reduce the consumed current, and therefore the power, by connecting a diode type D132-80-10 in series with the heater on a powerful heat sink-radiator.

There is another quite acceptable technical solution: to power the spiral consuming significant current through both 16-ampere protection circuit breakers. You just need to connect the “heat generator” to two parallel sockets (each from its own protection circuit breaker) provided that the meter is rated for 30-40 A.

1 — wooden board; 2 — guide stop (nail without head); 3 — nichrome (wire Ø 1).

The easiest way to connect in parallel is using a special adapter-extension cord with one socket and two plug connectors attached to it. Insert one plug into the socket of the first circuit breaker — voltage appears on the second. After verifying with some indicator or test lamp that the phasing is correct, connect the second plug to the socket of the other circuit breaker. As a result, both sockets are connected in parallel.

There is another, safer method — to run a socket from the electrical panel (of course, through the meter). Moreover, the wire cross-section converted to copper should be at least 2.5 mm2. Such a socket should be powered through a circuit breaker with a trip current of 25 A.

The task is significantly simplified if an electric stove is installed in the apartment. This means there is already a socket rated for 25 — 40 A. After verifying that the network voltage is 220 V and the wire cross-section is sufficient, connect the “heat generator” here as well.

For exotic enthusiasts, I can offer as a heater… a door spring. However, it must be connected through a welding-type transformer with forced cooling. After all, the resistance of such a spring is on the order of 1 Ohm. At a voltage of 60 V, a current of 60 A will flow through it, meaning the transformer will deliver 3.6 kW to the load, which is what is required.

“Modelist-Konstruktor” No. 6’98, L. LOBOV