Vertical tail plane is a keel and rudder. The keel is structurally made integral with the fuselage dvuhlonzheronnoe scheme. Frontal part (to the front spar) covered with plywood. The rear spar is the rear bulkhead of the fuselage.

The rudder design is similar to the Elevator or Aileron. It also consists of a spar, straight and diagonal ribs and rib wrap. The front part of the steering wheel to the longitudinal sewn plywood. Nodes sample represent the fork bolts. The control lever is fixed at the bottom of the spar. There is mounted the attachment point of the struts. All the tail surfaces covered in fabric.

Main landing gear – two-wheel spring type. Curved spring steel 65G; its ends are attached to the wheels size 300×125 mm. spring Mounting to the fuselage is a steel plate and a couple bolts on each side, which spring is clamped and thereby fixed relative to the fuselage.

Tail wheel is a attached by two bolts to the fuselage strip of steel 65G, which is screwed to the bottom bearing Cup.

The Elevator control hard using the handle (Yak-50), aluminum rods and intermediate units. Control of the ailerons are tight also. The actuator of the rudder – cable, using a suspension lever pedals, steel cables with a diameter of

The power plant of the aircraft based on the engine RMZ-640 mounted on Motorama upside – down cylinders. On top of the engine, an upper pulley V-belt gear belt tension. Fiberglass hoods are attached with screws to the self-locking anchor nuts on the fuselage and the connecting ring.

The propeller bonded with an epoxy resin of pine plates, and then processed according to patterns, covered with fiberglass and painted. “Argo-02” was used several such screws with different diameters and pitches. One of the most acceptable for its aerodynamic qualities has the following characteristics: diameter 1450 mm, 850 mm, the chord is 100 mm, static thrust is 85 kgs. Spinner is laminated of fiberglass on epoxy binder and put on the dural ring. Mount coke to the propeller – screws.

The fuel system of the aircraft consists of fuel tank capacity 14 l fuel pump, fuel filter, check valve, fire hydrant, drain, tee and piping system.

The fuel tank is welded from aluminum sheet with a thickness of 1.8 mm. At the bottom is a consumable container, which is welded consumables and drain fittings, top – fuel filler neck with drainage, intra – connected partitions to prevent foaming of the fuel. The tank is attached to two beams by tie ribbons with felt pads.

System receivers air pressure (LDPE) consists of a tube made of LDPE (Yak-18), mounted on the left wing of the plane, tube, dynamic and static pressure, the connecting rubber hoses, dispenser and devices.

Length, m……………………………………………4,55

Height, m……………………………………………1,8

Wing span, m…………………………………..6,3

Wing area, m2………………………………6,3

The narrowing of the wing………………………………………0

End wing chord, m……………………..1,0

SAH, m………………………………………………..1,0

Wing setting angle, deg…………………..4

V-angle, degrees…………………………………………..4

The sweep angle, deg…………………….0

Wing profile……………………….R-Ø 15,5%

The area of the Aileron, m2………………………..0,375

The magnitude of the Aileron, m………………………………..1,5

Deflection angles of Aileron, deg.:

up…………………………………………………..25

down…………………………………………………….16

Wingspan, m……………………………………..1,86

Area, m2…………………………………..1,2

The setting angle, deg………………………..0

The RV area, m2……………………………….0,642

Area IN m2…………………………………0,66

Height IN m………………………………………1,0

The PH area, m2…………………………………0,38

The angle of deviation of PH, grad…………………- 25

The angle of deviation of RV, hail………………….- 25

The width of the fuselage at the cabin, m…………0,55

The height of the fuselage at the cabin, m………….0,85

The base chassis, m………………………………………2,9

Wheel track, m……………………………………1,3

Engine:

type……………………………………………RMZ-640

power, HP……………………………………..28

max. rotation frequency, Rev/min ………5500

Gear:

type………………………………..V-belt,

chetyrehluchevoy

gear ratio…………………………….0,5

straps, type…………………………………….A-710

Fuel………………………………..petrol A-76

Oil…………………………………………..MS-20

The diameter of the rotor, m…………………………………1,5

Step screw m……………………………………..0,95

Static thrust, kgf……………………………95

Weight of empty apparatus, kg…………………145

Maximum takeoff weight, kg………7235

Fuel capacity, l……………………………………15

Range

flight balance, % SAH…………24. ..27

The stall speed, km/h……………………72

Max. speed

horizontal flight, km/h……………..160

Maximum

the flying speed, km/h…………….190

Cruising speed, km/h…………………120

The speed of separation, km/h………………………….80

Landing speed, km/h……………………70

Rate of climb at ground, m/s………………2

Run, m…………………………………………….100

Mileage, m……………………………………………..80

Range

operational overloads…….+3..- 1,5

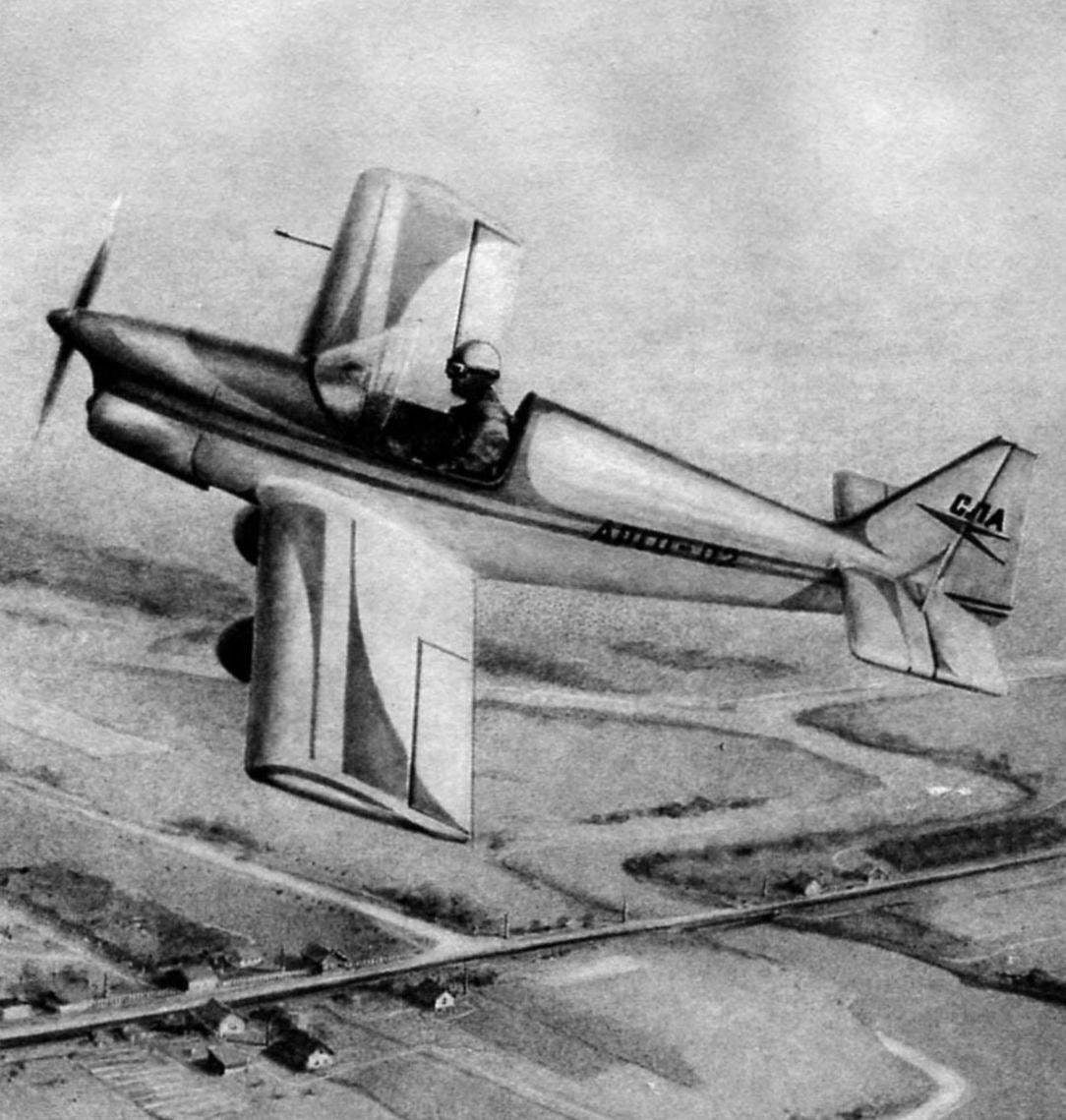

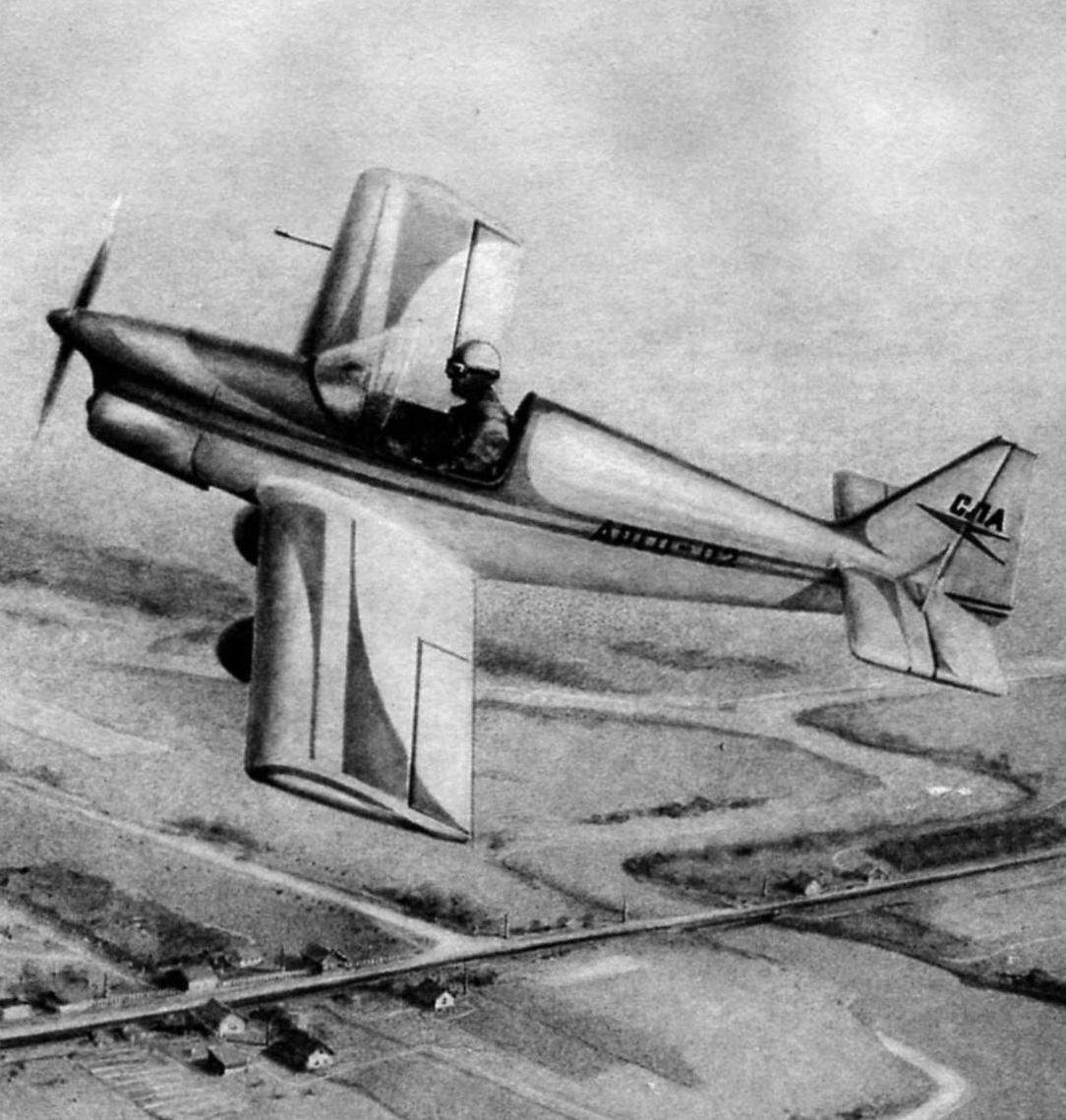

Is it possible nowadays to build your own plane? Tver aircraft enthusiasts Eugene Ignatiev, Yuri Gulak and Alexander Abramov answered this question in the affirmative, creating a winged single machine, later named “Argo-02”. The plane was successful: successfully flew on all-Union competitions, was the first winner of regional review-competition of Amateur aircraft in Yaroslavl. The secret to increased popularity of “Argo” Amateur aviators not the designer or the technological refinements of designers, but rather – their traditionalism. The designers managed to achieve a successful combination of waste over many decades of design methods of wooden cars of the 1920-ies and 1930-ies and modern aerodynamic calculations of aircraft of this class. This is perhaps one of the main advantages of the aircraft: its production does not require advanced plastics and composites, rental of high-strength metals and synthetic fabric with the pine timber, some plywood, fabric and enamel.

Is it possible nowadays to build your own plane? Tver aircraft enthusiasts Eugene Ignatiev, Yuri Gulak and Alexander Abramov answered this question in the affirmative, creating a winged single machine, later named “Argo-02”. The plane was successful: successfully flew on all-Union competitions, was the first winner of regional review-competition of Amateur aircraft in Yaroslavl. The secret to increased popularity of “Argo” Amateur aviators not the designer or the technological refinements of designers, but rather – their traditionalism. The designers managed to achieve a successful combination of waste over many decades of design methods of wooden cars of the 1920-ies and 1930-ies and modern aerodynamic calculations of aircraft of this class. This is perhaps one of the main advantages of the aircraft: its production does not require advanced plastics and composites, rental of high-strength metals and synthetic fabric with the pine timber, some plywood, fabric and enamel.