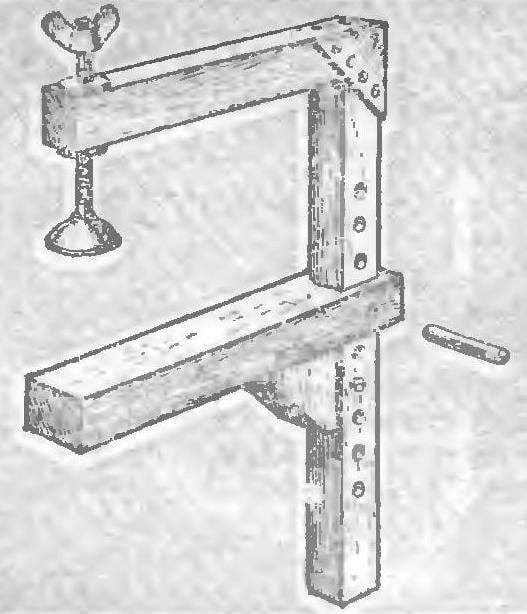

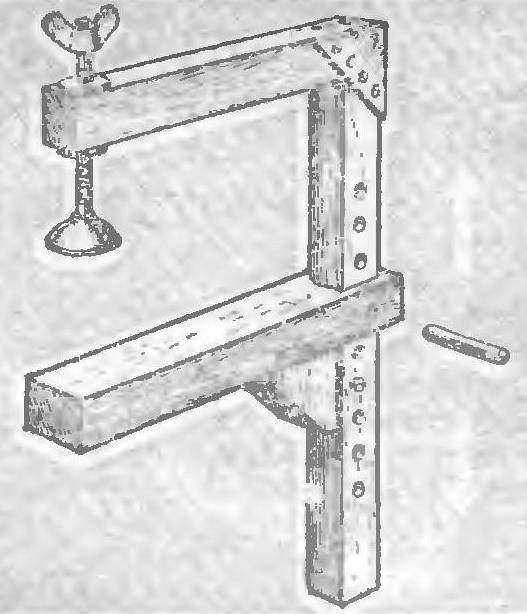

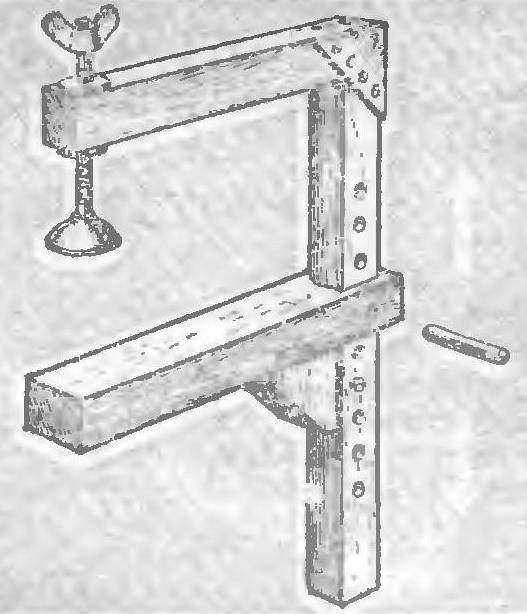

The range of action of conventional clamps is significantly expanded, if the emphasis is extensible, as the wrench. It is done so. In an l-shaped bracket drilled and cut the hole for the clamping screw, and in its longest part — the holes for mounting the movable jaw. It is fixed with a pin or screw of corresponding diameter.

V. DUDCHUK, S. kleschikha, Rivne region.

Recommend to read

FRAME TO THE MIRROR

FRAME TO THE MIRROR

MATERIAL: metal rod Ø3 mm, a rod of square cross section 8X8 mm, flat metal section 2X15 and 3X15 mm, plywood 10 mm thick, thin plywood, mirror, screws 4x10 mm, colorless furniture... DURABLE TENT

DURABLE TENT

Undoubtedly of interest to many tourists are the publication of the journal "modelist-Konstruktor". But they mainly describe the various vehicle designs and less emphasis on other...

The range of action of conventional clamps is significantly expanded, if the emphasis is extensible, as the wrench. It is done so. In an l-shaped bracket drilled and cut the hole for the clamping screw, and in its longest part — the holes for mounting the movable jaw. It is fixed with a pin or screw of corresponding diameter.

The range of action of conventional clamps is significantly expanded, if the emphasis is extensible, as the wrench. It is done so. In an l-shaped bracket drilled and cut the hole for the clamping screw, and in its longest part — the holes for mounting the movable jaw. It is fixed with a pin or screw of corresponding diameter.