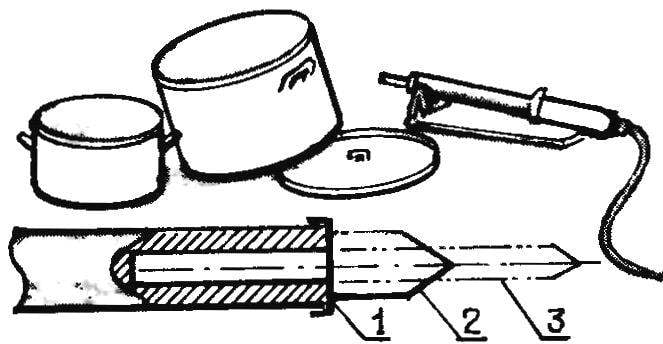

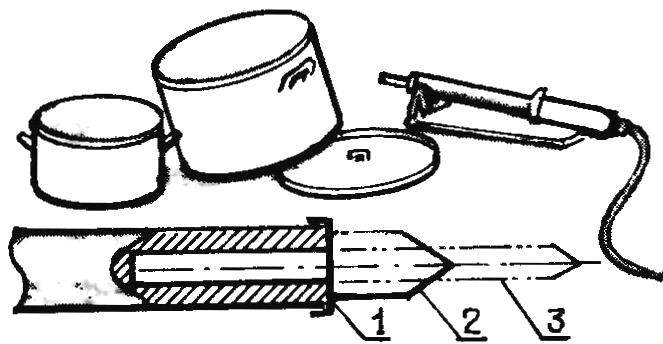

Often tan, what power you have at your disposal a soldering iron “barely enough” to firmly interconnect the major parts, say, or to patch the leaky bottom of the pan. Even pre-heating on the stove does not work — it turns out poor soldering, loose. For such cases, it is possible to make the soldering of the additional rod. Working with a thickened part, the length of which must be in 2-2,5 times less than the former, “standard”, of the rod, and the diameter, respectively, more (see Fig.). Calculations (and practice) show that this is equivalent to “increase” the power of the soldering iron by 20 percent. With no additional power consumption!

Often tan, what power you have at your disposal a soldering iron “barely enough” to firmly interconnect the major parts, say, or to patch the leaky bottom of the pan. Even pre-heating on the stove does not work — it turns out poor soldering, loose. For such cases, it is possible to make the soldering of the additional rod. Working with a thickened part, the length of which must be in 2-2,5 times less than the former, “standard”, of the rod, and the diameter, respectively, more (see Fig.). Calculations (and practice) show that this is equivalent to “increase” the power of the soldering iron by 20 percent. With no additional power consumption!

The conversion of low-power soldering iron to work with “large parts”:

1 — body of an electrosoldering iron with the heating element, 2 — new stem (shorter, with a thickened head and the enlarged tip), 3 — the “regular” terminal soldering iron.

N. FEDOTOV