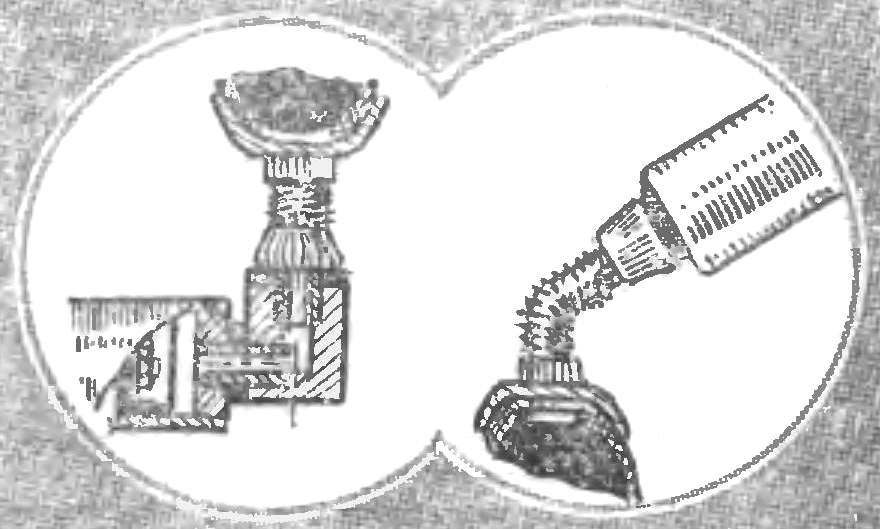

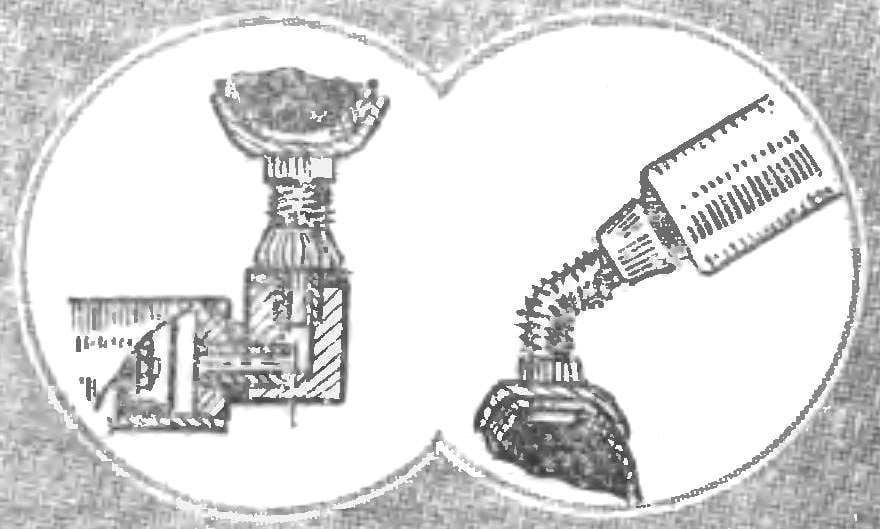

Pumping a Bicycle tire pump regular takes often more time than similar work at the motorist. The main reason is air leakage through the connecting rubber tubing to the pump and the nipple of the wheel. Yes, and the tube often fails. I propose to replace this unreliable part with a metal adapter. Thread in its inner axial hole should be of such length that when nevinchany on the nipple to stop it Juice a shank with a thread outlet of the pump is perpendicular to the plane of the wheel. Wide washers cut from rubber sheet with a thickness of 2-3 mm, securely seal end joints. If you manage not damaging the threads, a little bend the body of the nipple to the side, as shown in the figure, neither the tube nor the adapter is not required: the pump can be connected directly to the nipple.

Pumping a Bicycle tire pump regular takes often more time than similar work at the motorist. The main reason is air leakage through the connecting rubber tubing to the pump and the nipple of the wheel. Yes, and the tube often fails. I propose to replace this unreliable part with a metal adapter. Thread in its inner axial hole should be of such length that when nevinchany on the nipple to stop it Juice a shank with a thread outlet of the pump is perpendicular to the plane of the wheel. Wide washers cut from rubber sheet with a thickness of 2-3 mm, securely seal end joints. If you manage not damaging the threads, a little bend the body of the nipple to the side, as shown in the figure, neither the tube nor the adapter is not required: the pump can be connected directly to the nipple.

WITHOUT LEAKAGE

Denis TITOV, Odintsovo, Moscow region