Moving from graphs to real structures, it is impossible not to note: in vehicles AC to improve and facilitate the use a powerful welding transformers (magnetic circuit — special electrical iron with the steep characteristic) deliberately inflated the voltage in the secondary winding, reaching up to 80 In, although to support the arc and the weld metal in the weld zone sufficiently 25-36 V. Have to put up with excessively large weight and dimensions of the apparatus, the increased spending power. Lowering the voltage transformed to the secondary circuit, to 36 In, 5-6 times to lighten the weight of “svarochnik”, to bring its size to the size of a portable TV while improving other performance characteristics.

But as in the low-voltage winding to ignite the arc?

Fig. 1. Graphs explaining the process of welding on AC (a) constant and (6) the current.

Fig. 2. A circuit diagram of a welding machine DC.

Fig. 3. The volt-ampere characteristic “svarochnik”.

The solution was input into the secondary circuit of the diode bridge with the condenser. As a result, the voltage at the output of the modernized “svarochnik” increased by almost 1.5 times. The experts confirmed in practice: when exceeding the 40-volt barrier DC arc easily ignited and steadily lit, allowing you to weld thin body metal.

The latter, however, is easily explained. With the introduction of the scheme high capacity characteristics of the welding machine also turns steeply dipping (Fig. 3). Created by the primary capacitor high voltage facilitates the ignition of the arc. And when the potential on the welding electrode will fall to U2 of the transformer (operating point “A”) will result in a sustainable arc with the weld metal in the weld zone.

the author of “svarochnik” you can collect even at home on the basis of industrial power transformer 220-36/42 In (these are usually used in systems safe lighting and powering low-voltage factory equipment). Convinced of the integrity of the primary winding comprising, normally 250 turns of insulated wire with 1.5 mm2, check secondary. If their state is unimportant, all (except a working network winding) without regret removed. And in the void wound (to fill the “window”) of the new secondary winding. For recommended power transformer 1.5 kVA LRA 46 coils of copper or aluminum bus-section 20 mm2 with solid insulation. Moreover, as the tyre is quite suitable cable {or several twisted into a bundle of insulated solid wires) for the total cross section of 20 mm2.

THE CHOICE OF THE CROSS SECTION OF THE ELECTRODES DEPENDING ON THE POWER TRANSFORMER

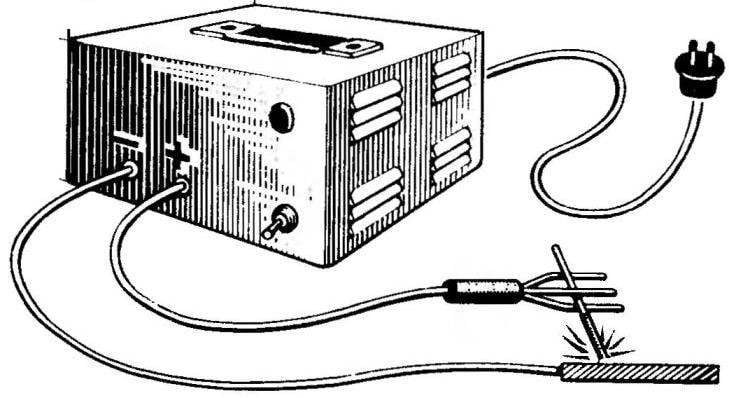

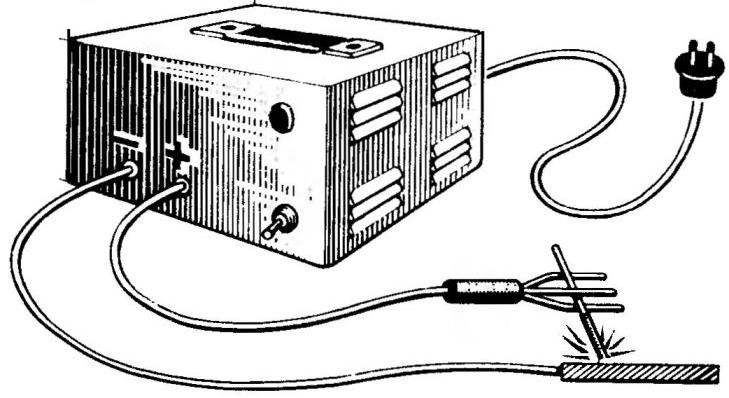

Fig. 4. Homemade machine for welding on direct current.

The bridge rectifier can be constructed from a semiconductor diode with operating current of 120-160 And setting them on the heat sinks-heat sinks 100×100 mm. to Place such a bridge is most convenient in a single housing with transformer and capacitor, moving on textolite the front panel 16 amp breaker, the eye warning lights On, and the terminals “plus” and “minus” (Fig.4). And to connect to the electrode holder and the land use along the segment of single core cable of appropriate length section of copper 20-25 mm2. As for the welding electrodes, their diameter depends on the power used by the transformer.

And again. When testing is recommended, disabling the camera (in 10 minutes after welding) from the network, test the thermal behavior of the transformer, diode bridge and capacitor. Only after making sure that everything is normal, you can continue working. After all, overheated “SVA-Rechnik” — the source of danger!

Other requirements it is useful, I think, to note that the equipment must be equipped with iscrewedadonkey mask, gloves and a rubber Mat. The place where you perform welding, equipped with the requirements of fire safety. Besides, it is necessary to track that there were rags, other combustible materials, and the connection of “svarochnik” to the network to comply with the rules of electrical safety via a powerful plug connector fuse box is to enter the building.

V. KONOVALOV,

Irkutsk

Recommend to read SPEAKERS Popularity of electronic musical instruments, an increasing number of Amateur youth and pop ensembles caused an increased demand for powerful, high quality low-frequency amplifiers. The... Po-2 (U-2) Training U-2 aircraft - single-engine biplane of wooden construction with fixed landing gear, was designed at the factory number 1 in Moscow under the leadership of H. H. Polikarpov. His... Scroll back to top

Advantages of welding machines DC before they “perimentally brothers” is well known. It’s mild arc, and the ability to connect thin-walled parts, and less spatter, and the lack of nepreverjenih sites. Even the annoying (and, as it turned out, bad acting people) cod is not. And all because there is no major inherent to the welding apparatus of the alternating current feature — intermittent arcing at the overflow of the sinusoid of the supply voltage through zero (Fig.1).

Advantages of welding machines DC before they “perimentally brothers” is well known. It’s mild arc, and the ability to connect thin-walled parts, and less spatter, and the lack of nepreverjenih sites. Even the annoying (and, as it turned out, bad acting people) cod is not. And all because there is no major inherent to the welding apparatus of the alternating current feature — intermittent arcing at the overflow of the sinusoid of the supply voltage through zero (Fig.1).