CHAINMAIL FOR THE METAL. Like invisible arrows, affects the corrosion of metal surfaces operating in hostile or wet environments. Rust stains, caked wounds cover almost the entire surface of the structure, reducing its strength, significantly reducing the service life. Widely used for corrosion control coatings are not always effective, especially in high temperatures.

CHAINMAIL FOR THE METAL. Like invisible arrows, affects the corrosion of metal surfaces operating in hostile or wet environments. Rust stains, caked wounds cover almost the entire surface of the structure, reducing its strength, significantly reducing the service life. Widely used for corrosion control coatings are not always effective, especially in high temperatures.

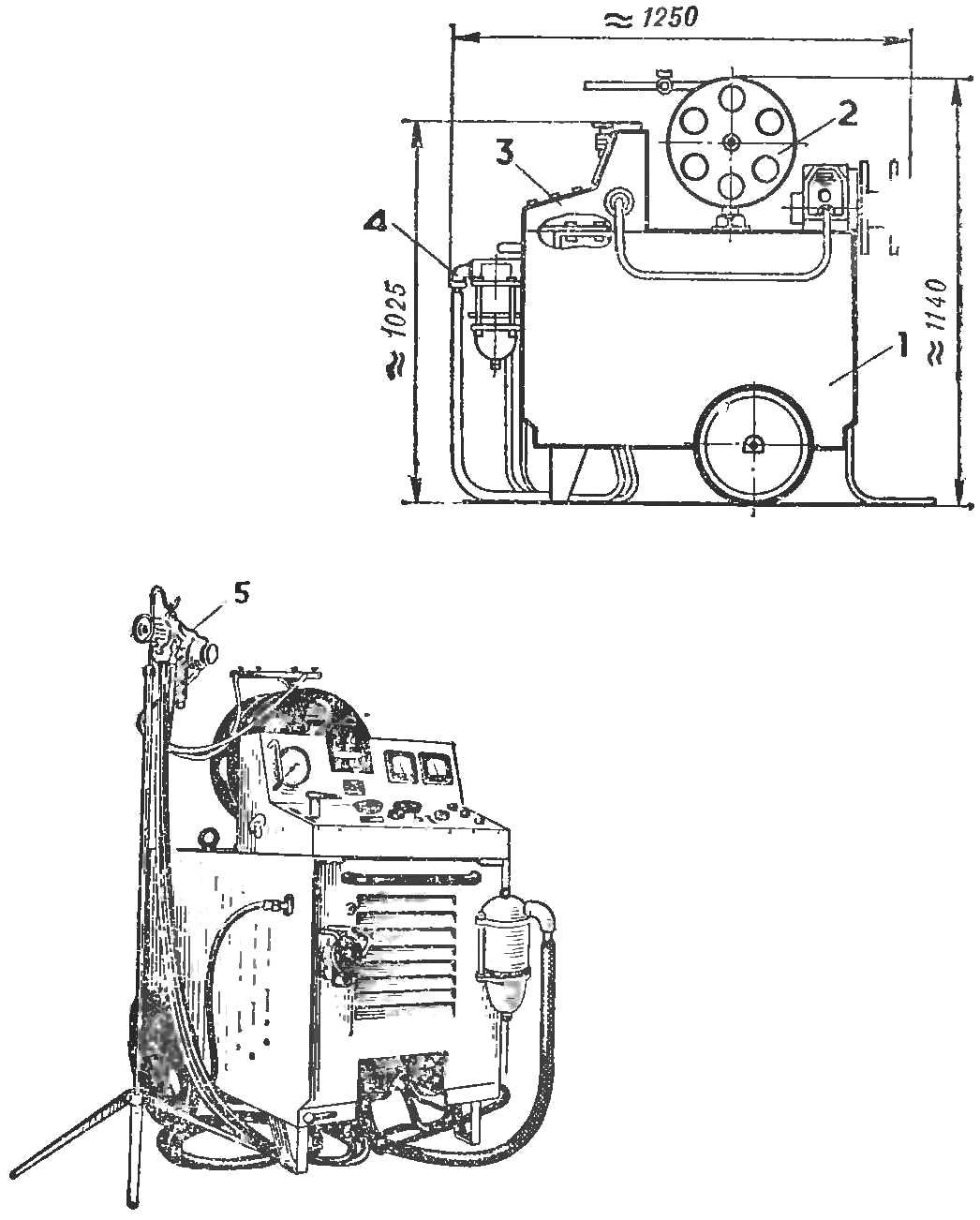

A kind of coat of mail, impenetrable to corrosion, protect any design created in the Institute Vniiavtogenmash Assembly for electric arc metallization (BM-1). This device napisat for the product a thin film of zinc or aluminum. Moreover, the operation can be done outdoors, directly in the mounting pad, since the device has relatively small dimensions and weight that allows its use in any workplace.

Assembly (Fig. 1) consists of a kit including rectifier EDC-301, stand on it with the coil wire, remote control, air filter and the electric head, which is the main working tool. Wire, melted by electric arc, atomized jet, evenly covering the surface to be protected.

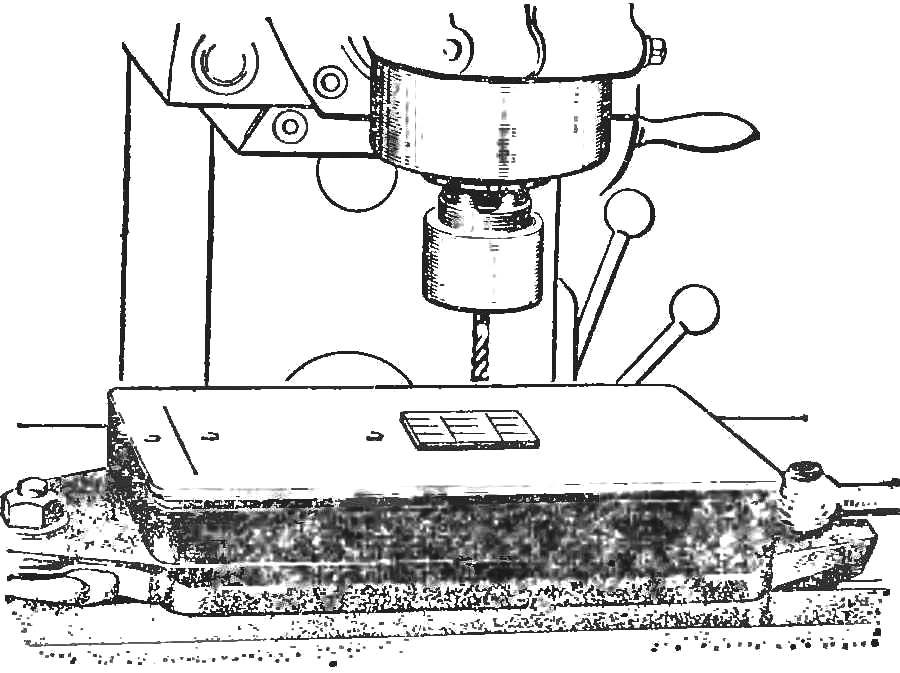

Fig. 1. Equipment for metallization and the schematic:

1 — rectifier (power can be supplied from three phase network 220/380 V), 2 — coil wire 3 — control panel 4 — air filter 5 — arc head.

Indoors the unit can be used for applying anti-corrosion zinc or aluminum film, as well as wear-resistant, friction-resistant coatings made of molybdenum steel, nichrome and other metals.

The installation of electric arc metallization not only provides high quality cover and great performance: an hour can be sprayed to 25 kg of zinc, more than 7 kg of aluminum, 6 kg of steel or molybdenum. The supply hoses of the working heads give the operator the necessary maneuverability within a radius In meters, but if necessary can be doubled or even more. Remote control provides operator protection when coating, and special devices guarantee safe operation.

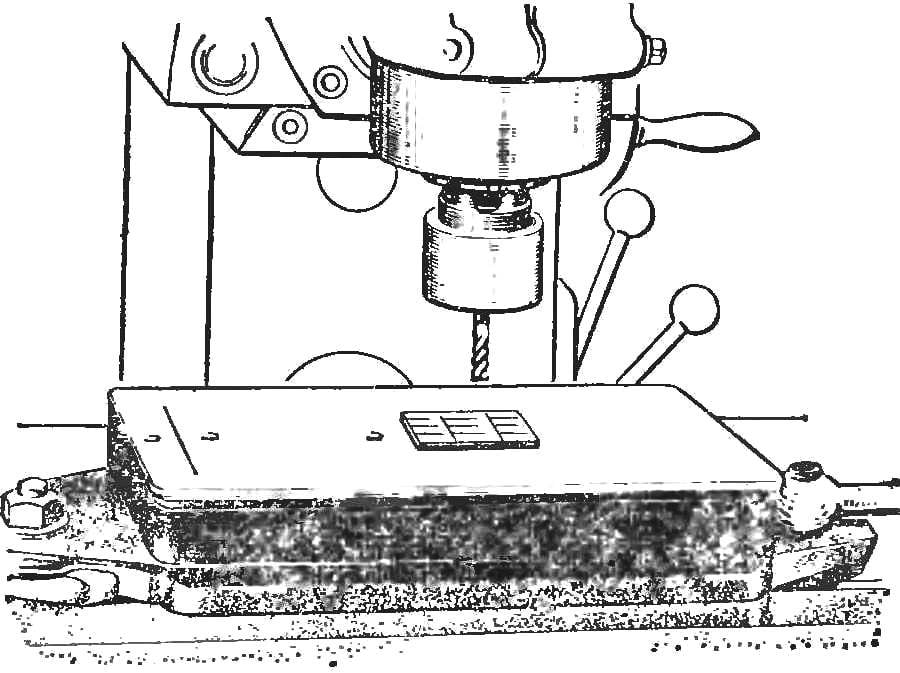

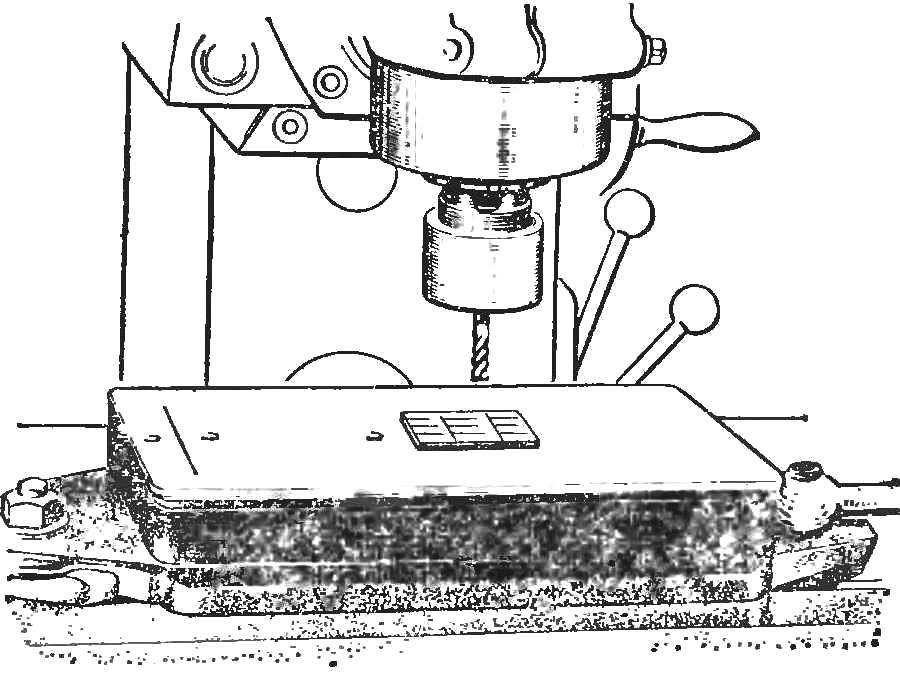

Fig. 2. Ice “Vice” — mount detailed primorazhivaniem.

ICE “VICE”. About the ship, wedged in the ice, say he fell into the icy vise. Isn’t that the expression suggested by the Leningrad innovators idea to use when machining such a familiar and yet surprising property of water: samuraiwars to turn into a solid. A few years ago in the USSR national economy was shown the original method of “packing” in the ice brittle, crease parts before machining them on a milling, drilling or turning machines. Frozen in ice, they were treated as a single item, successfully withstanding the applied load, from which out of the ice block is inevitably deformed.

After the proposal of the Leningrad — securing small parts on the machine method… primorazhivaniem.