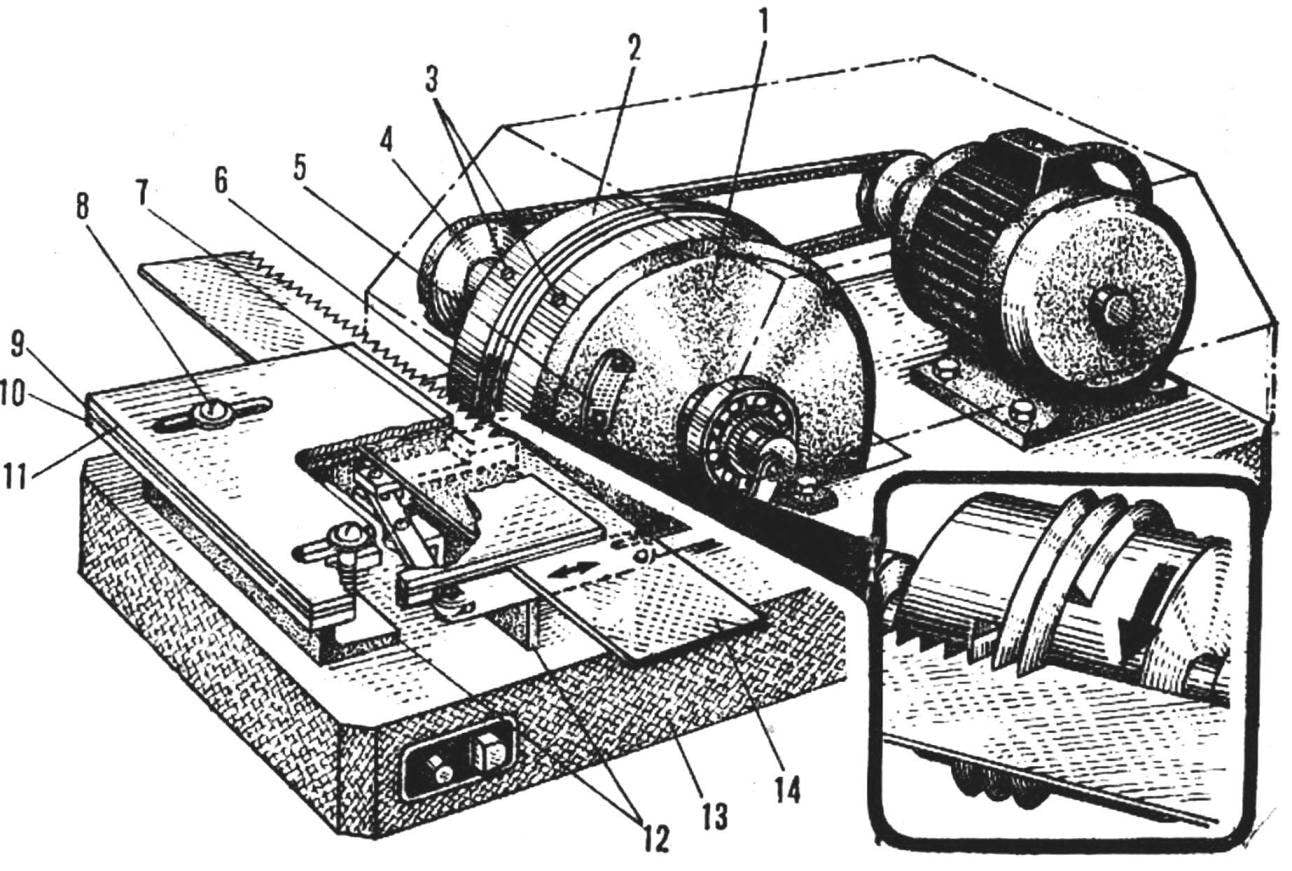

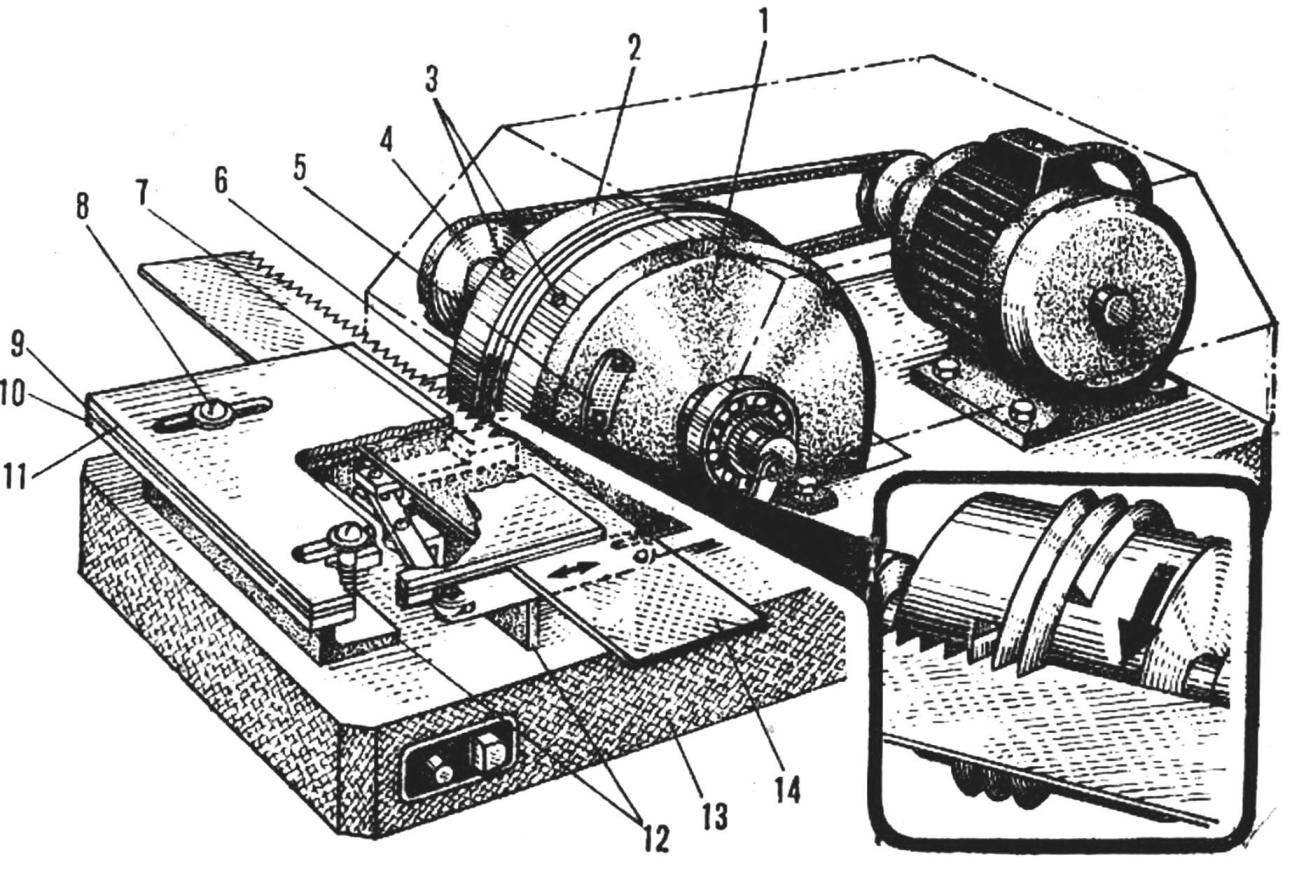

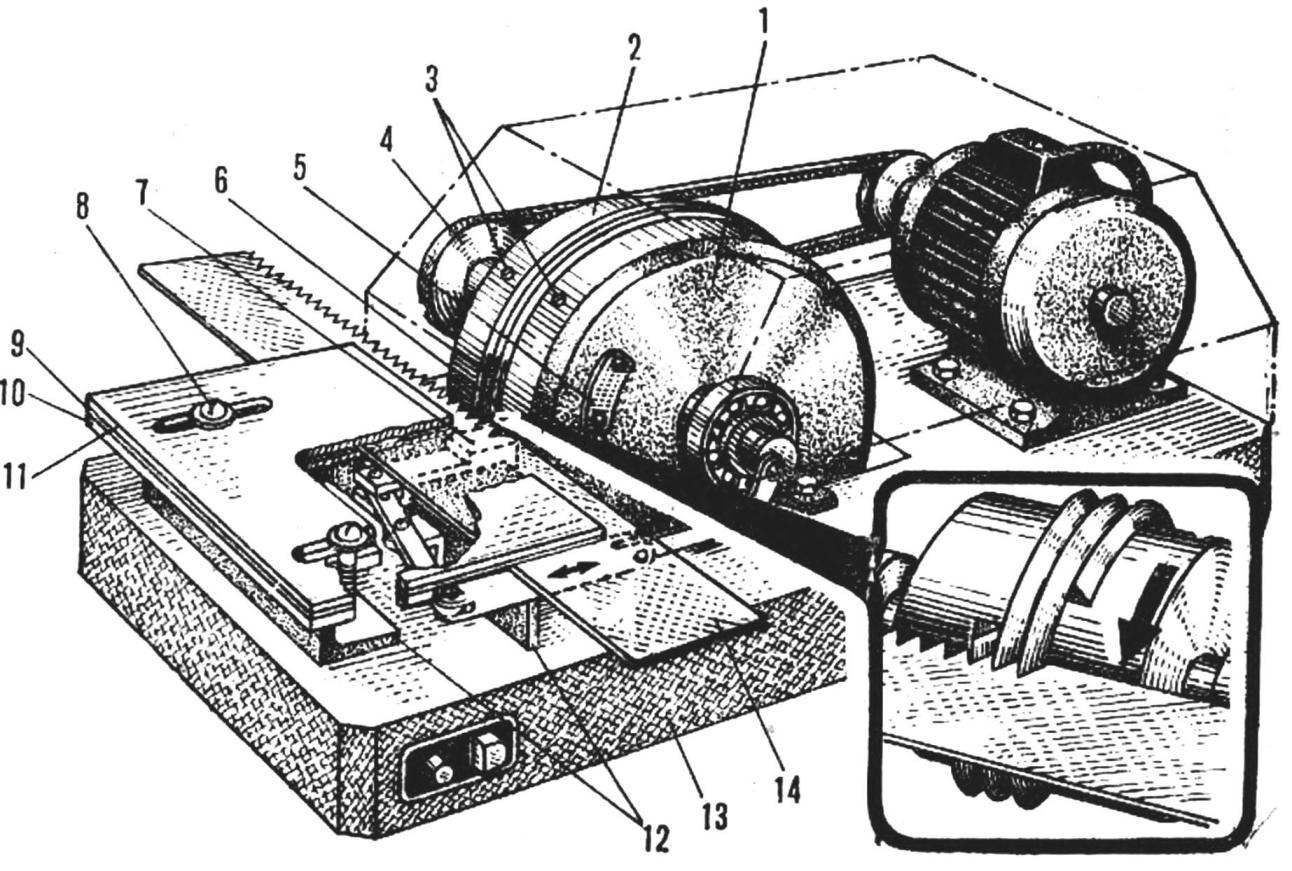

The principle of operation of this device for cutting, or rather, cutting out of teeth on the blades for the hacksaw is simple. Its main part is a wheel with a cage, fortified it with four screws. On the surface of the cage is cut two or three strands of outer thread with a pitch, height and profile of the future teeth of a saw. Extreme thread thread partly removed with a cutter, or a chisel and chopped off the right angle: the end will perform the role of a punch. To increase the impact force to the flywheel attached two opposed.

The principle of operation of this device for cutting, or rather, cutting out of teeth on the blades for the hacksaw is simple. Its main part is a wheel with a cage, fortified it with four screws. On the surface of the cage is cut two or three strands of outer thread with a pitch, height and profile of the future teeth of a saw. Extreme thread thread partly removed with a cutter, or a chisel and chopped off the right angle: the end will perform the role of a punch. To increase the impact force to the flywheel attached two opposed.

From the axis of the flywheel with a system of levers driven by a matrix. It along the guide groove in the table that is approaching the flywheel at the moment when the punch returns back after the impact and cutting out another tooth. In one revolution of the flywheel on the canvas appears one tooth, and, in addition, it is applied forward on the pitch holder. To get the full height of the teeth and prevent distortions of the matrix and are limited to the saw blade holding plates. Their regulation is performed by two screws; easy to use and the wing nuts.

Device for cutting out the teeth on the canvases:

1 — handwheel, Ø 150 mm, 2 — clip, 3 — fastening screws 4 — clutch pulley, 5 — counterweight, 6 — plug, 7 — matrix, 8 — adjusting screw, 9, 10, 11 and retaining plates 12 — table 13 — base, 14 — tracks.

The diameters of the driven and driving pulleys are selected depending on a desired speed feed forward. The fixture top is closed with a cover. If necessary, have a different purpose and size of the web is a few replacement clips in a pair of matrices.

N. SHILOV, the head of the circle “Skillful hands” of secondary school № 92 of the city of Karaganda