I’m a subscriber “Modeller-designer” already since 1972. Much of that time has changed, but the content of the magazine, I (and not only me) are quite satisfied. Let increased its subscription price (which is of course not pleased, but not scared — I understand the difficulties of the editors), I’ll write a journal, yet it will exist. Not going to list those topics in it that interest me the most is all that can be done in a home workshop, ranging from simple stools to, for example, motoriety. I also do many things with their hands (friends call me by this “local Kulibin”).

I’m a subscriber “Modeller-designer” already since 1972. Much of that time has changed, but the content of the magazine, I (and not only me) are quite satisfied. Let increased its subscription price (which is of course not pleased, but not scared — I understand the difficulties of the editors), I’ll write a journal, yet it will exist. Not going to list those topics in it that interest me the most is all that can be done in a home workshop, ranging from simple stools to, for example, motoriety. I also do many things with their hands (friends call me by this “local Kulibin”).

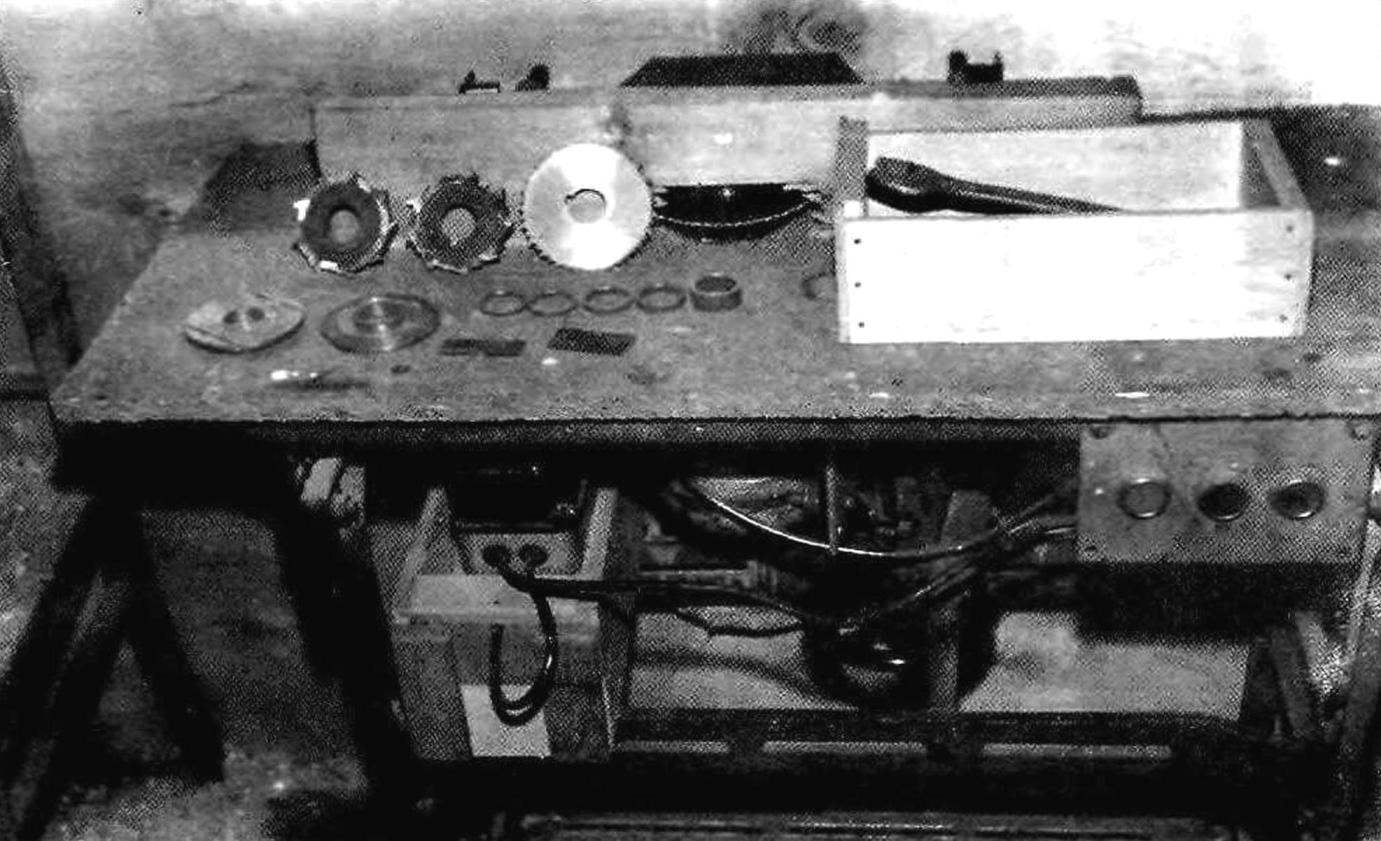

Answering the call log to the craftsmen to sponsor, I want to offer to the readers of their development — not the usual woodworking machine. I did back in 1986, but he acts today. Since that time the machine was manufactured a lot. Judging by the statements of friends, who watched me work on the machine or personally had manufactured it necessary for himself details, the design turned out well. Each of them would like to have one, and three even made their own kind, with slight modifications. To the description and drawings, I attach two pictures, really Amateur. At the moment I have made some improvements in the machine, although not fundamental, but improving its performance. In this regard, the described design is slightly different from the pictures.

According to the principle of the machine is a circular saw, but working on it — the blade — in contrast to conventional, rotates in a vertical plane and in a horizontal (like a circular saw “on the contrary”). In addition, there is the possibility of using two types of cutting tool: shaped cutter (or combination of cutters), and a dismountable nozzle with replaceable knives. If necessary, the machine can be configured as a wheel grinder for sharpening, such as knives for planer, blade width up to 250 mm.