I’m sure many amateur car builders face the problem of glazing the body when building their vehicle. Most of them solve this by “tying” themselves to the sizes and shapes of automotive glass used on production models. I, however, took the risk of equipping my “jeep” with triplex-type glass, cut to the required dimensions myself. For this, I used a diamond cutter. I scored lines on both sides of the triplex with it, then tapped them until a crack appeared along the entire length. Then I heated the part to be removed with an alcohol lamp flame. The film connecting the triplex layers heated up, which allowed me to pull the glass parts apart until a gap appeared between them. After that, I only needed to cut the film with a sharp knife and dull the uneven edges of the glass with sandpaper.

This method is quite simple and productive; but it’s only good for those who have extensive experience with regular glasswork—only an experienced craftsman can guarantee that when tapping, the crack will go in the right direction. Therefore, after ruining several pieces of glass, I took a more complex path—I made a special machine from available materials.

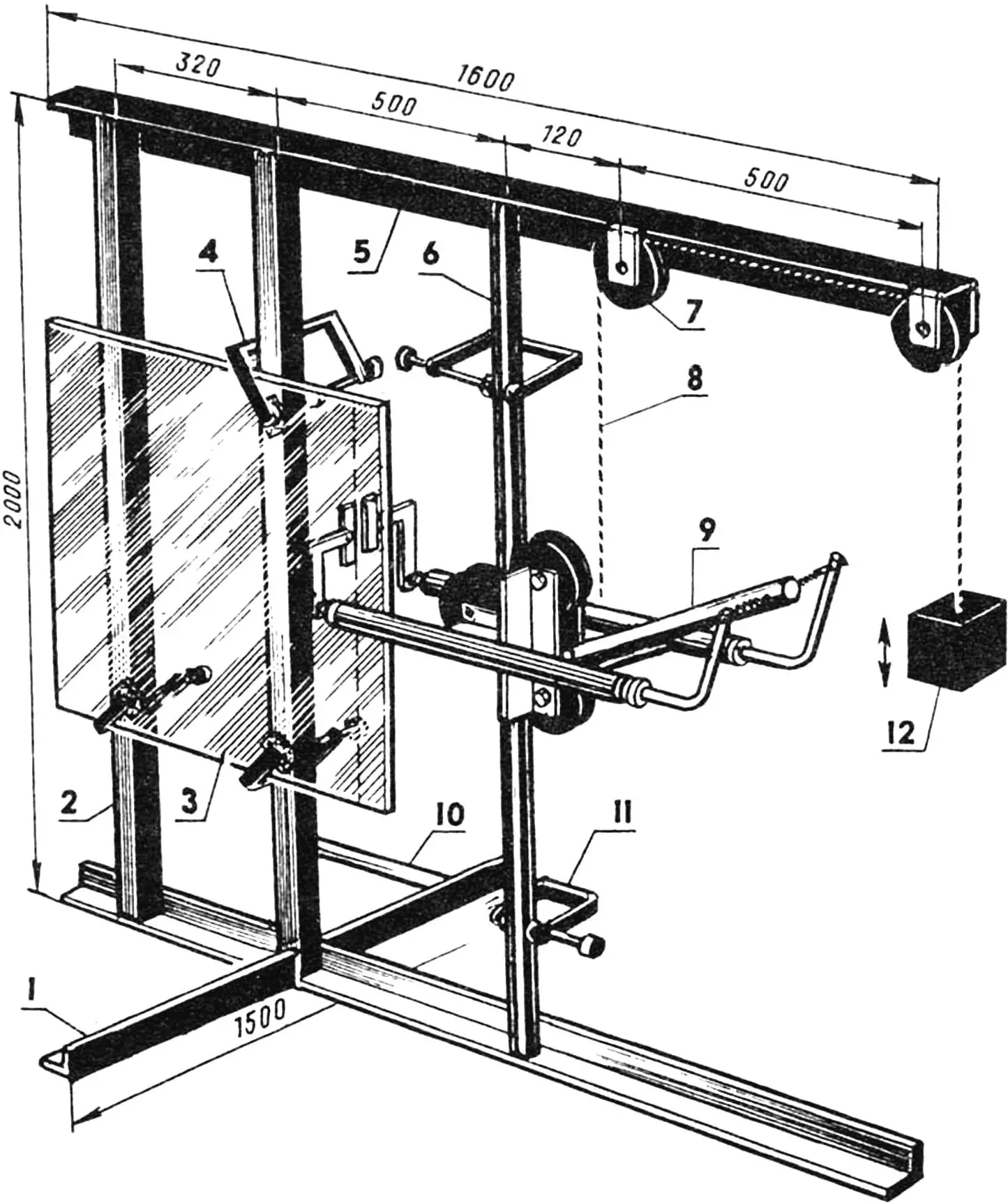

1 — horizontal support (steel angle 50×50), 2 — vertical post (steel angle 50×50, 2 pcs.), 3 — glass being processed, 4 — clamp (3 pcs.), 5 — horizontal tie (steel angle 50×50, 2 pcs.), 6 — guide (steel pipe Ø 48), 7 — pulley (steel, 2 pcs.), 8 — nylon cord Ø 6, 9 — carriage assembly, 10 — brace (steel strip 50×2), 11 — limit clamp (2 pcs.), 12 — counterweight.

Using the machine allows not only to minimize the percentage of defects but also to cut glass with slight curvature. No special qualifications are needed to use it. The only drawback of the device is low productivity, but in single-unit production conditions, this is completely unimportant.

The triplex cutting device consists of two parts: a stationary frame and a carriage with cutters moving along it. The frame is welded from 50×50 mm steel angles and a 48 mm diameter steel pipe.

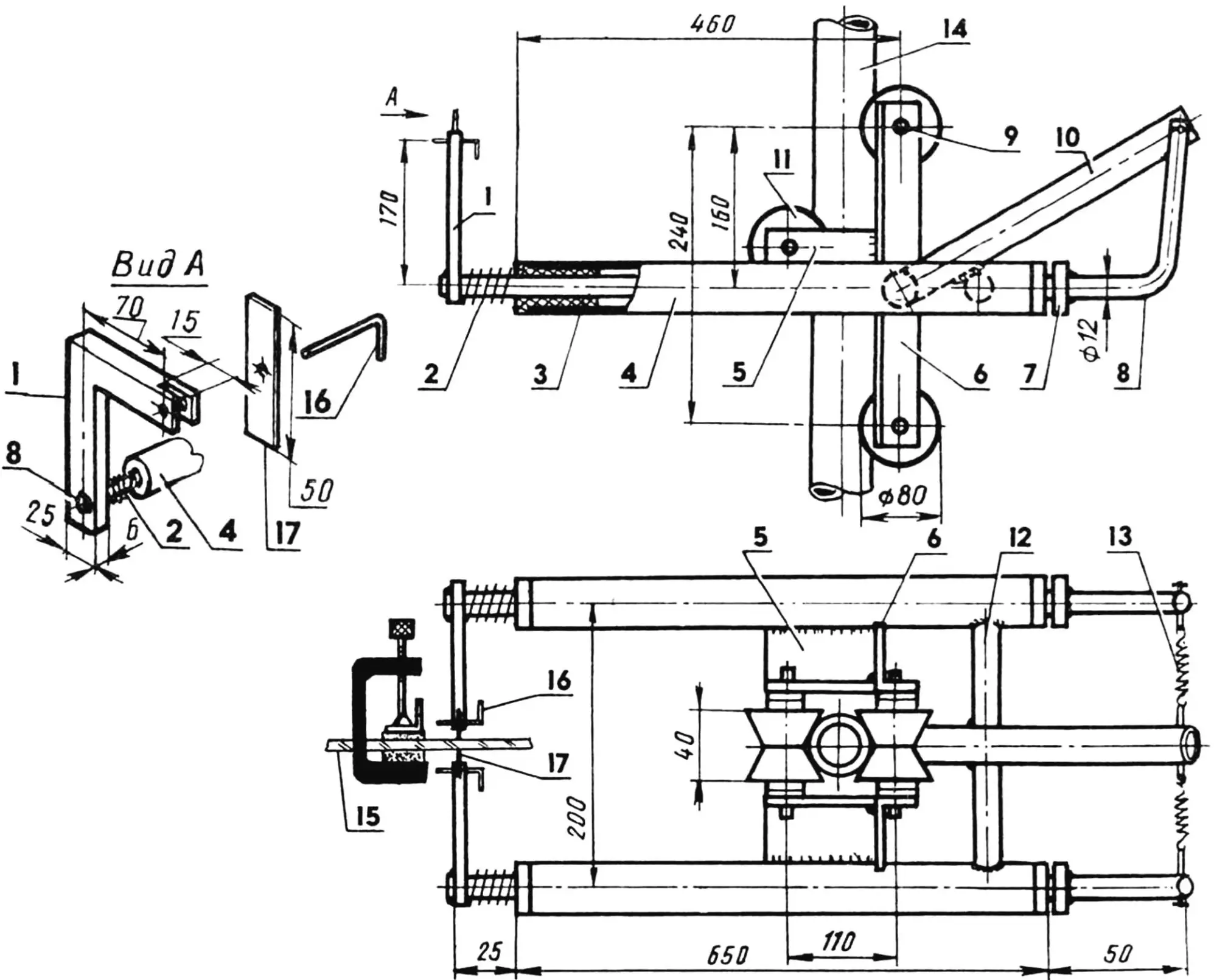

The carriage is a simple device that moves along the vertical post of the frame on three wheel-spools. As cutting tools, hacksaw blades with diamond coating purchased from a hardware store are used. The blades are cut with metal shears, and holes are drilled in them for fixing pins. In addition, the glass blank is also attached to the vertical posts of the frame with clamps through porous rubber pads.

1 — cutter holder (steel, 2 pcs.), 2 — compression spring (2 pcs.), 3 — bushing (Teflon, 4 pcs.), 4 — cylinder (steel pipe 28×1, 2 pcs.), 5 — middle spool bracket (steel angle 45×45, 2 pcs.), 6 — upper and lower spool bracket (steel angle 45×45, 2 pcs.), 7 — washer (steel, 2 pcs.), 8 — holder bracket (steel rod Ø 12, 2 pcs.), 9 — spool axis (bolt M12, 3 pcs.), 10 — bracket (steel pipe Ø 27), 11 — spool (steel, 3 pcs.), 12 — transverse tie (steel pipe Ø 27), 13 — tension spring (2 pcs.), 14 — frame guide, 15 — glass being processed, 16 — fixing pin (steel wire Ø 2, 2 pcs.), 17 — cutter (hacksaw blade with diamond coating, 2 pcs.).

The glass is cut simultaneously from both sides. The pressure force of the cutters against it is adjusted by spring tension. To avoid skewing, which is unacceptable, the carriage should be moved up and down using a cord passed through two pulleys. A counterweight serves to lighten the work. Two clamps installed on the post are used as movement limiters. During work, the cut line is abundantly moistened with water from a foam sponge.

After “sawing” the glass, it remains to cut the film with a knife. Heating is not required, as the gap is wide enough.

If the triplex corners should be rounded, this is done by sequential cutting along tangents and then smoothing the edge on a grinder.

The glazing of my car made in this way has been serving excellently for two years now.

V. BEZRUKOV