This compact machine on the basis of drills is intended for wood and plastics. It allows you to cut bruski, boards, plywood, plexiglass and the PCB, cut the slats and shaped plank, milled grooves, carve the wood, polishing surfaces, drill holes, sharpen drill bits, chisels and other cutting tools.

Small size nd weight of the machine, simplicity of the device and use make it suitable for school classrooms and carpentry shops, laboratories children’s technical stations and pioneer Homes.

The machine consists of a wooden base. A u-shaped frame, stationary front and movable rear attendants. Drive is manufactured by industry drill ИЭ1032-1 with a Chuck for clamping of drills with a diameter of 9 mm. Electric drills? powered by a network voltage of 220 V, develops about 940 rpm.

In a circular saw machine is transformed in the following way. In the bracket fixed headstock fix the drill. In its cartridge is clamped one end of the mandrel, and the second is fixed by using the tailstock and live center. Install the lifting table together with a movable range and protective fence.

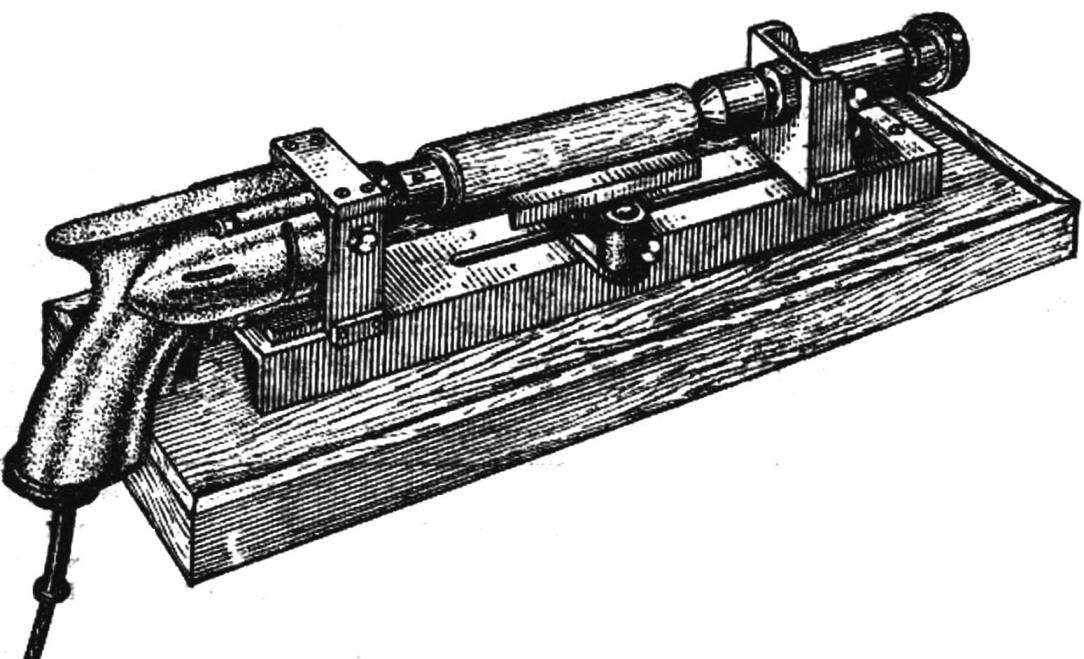

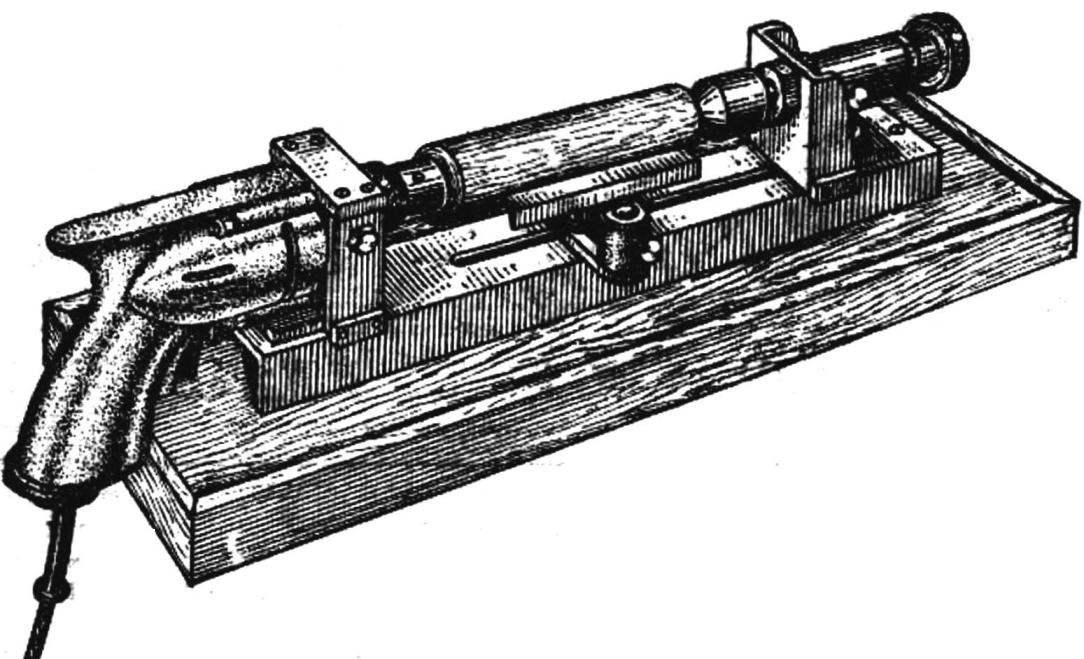

Fig. 1. Circular saw:

1 — wooden stand, 2 — U-shaped frame, 3 — drill, 4 — fixed headstock, 5 — mandrel saw blade, 6 — lifting table, 7 — drank 8 — guard 9 — bracket with a ruler, 10 ” rotating center, 11 — tailstock.

The presence of a movable and rotatable line provides Poluchenie rectangular and oblique rods and bars. Lifting table facilitates the production parts, as well as slots and grooves in the bars. The machine can cut the slats with a thickness of 2 to 50 mm and a width of from 2 to 120 mm as wood and plastics.

In the latter case, as saws use a milling cutter with fine teeth.

Circular saw easy to convert to a lathe for wood. To “that off the table and the mandrel in the Chuck of a drill clamped another, with teeth and fixed on the frame support for the knives, or chisels. At the same time see that the upper part of the support area was at the centre of the tailstock.

After adjustment between the gear mandrel and the rotating center is firmly clamped wooden workpiece, which in the beginning prepare, obtachivaya semicircular a chisel, and then treated with a tool with a beveled cutting portion. During work make sure that the distance between the support and the item does not exceed 5 mm for the convenience of working with the tool.

Fig. 2. Turning option:

1 — perforated mandrel, 2 — seat angle, 3 — bracket.

Fig. 3. Drilling machine:

1 — drill, 2 — fungus.

As the lathe allows to produce, for example, handles for tools, as well as turned parts of various configurations.

And finally, another transformation, the flock is in the drill. It is necessary to remove the reference movable area, the center and the toothed mandrel; the Chuck of a drill to hold the drill bit in the tailstock instead of the center to insert the fungus. The installation distance between the tailstock with a fungus, and drill bit should correspond to the thickness of the part.

Described compact universal machine for working wood and plastics awarded a bronze medal VDNH USSR.

F. PROKSCH, V. SHILOV

Recommend to read DOSIMETER RIDER For reliable operation the two-stroke engine is a very important proportion of oil content in gasoline. In order to accurately observe it, make a simple dosimeter. On the high... LaGG-3 The first flight of fighter I-301 with motor liquid cooling M-105P, created under the leadership of S. A. Lavochkin, V. P. Gorbunov and M. I. Gudkov and became the prototype of the...  This compact machine on the basis of drills is intended for wood and plastics. It allows you to cut bruski, boards, plywood, plexiglass and the PCB, cut the slats and shaped plank, milled grooves, carve the wood, polishing surfaces, drill holes, sharpen drill bits, chisels and other cutting tools.

This compact machine on the basis of drills is intended for wood and plastics. It allows you to cut bruski, boards, plywood, plexiglass and the PCB, cut the slats and shaped plank, milled grooves, carve the wood, polishing surfaces, drill holes, sharpen drill bits, chisels and other cutting tools.