Thrifty owners tradition harvested in the winter, various pickles, jams has always existed, but today it is particularly topical: products are expensive, and the purchasing power behind. At the same time the country is experiencing a suburban boom, and the plots — planting, greenhouses, fruit trees, berry bushes. Grown crop requires processing and canning for the winter, and that means rolling many cans you need the metal cap.

Thrifty owners tradition harvested in the winter, various pickles, jams has always existed, but today it is particularly topical: products are expensive, and the purchasing power behind. At the same time the country is experiencing a suburban boom, and the plots — planting, greenhouses, fruit trees, berry bushes. Grown crop requires processing and canning for the winter, and that means rolling many cans you need the metal cap.

However, the craftsmen tell you what to stock up on caps and should not be, and you just need to properly dispose of existing on the farm. And will this simple fixture that will allow, as evidenced by the letters of the inventors to the editor, neatly rolled open the cap, and deformed — straightening and re-use them any number of times.

In your journal No. 1, 83′ has been published a very useful machine for straightening metal caps used for glass “mayonnaise” jars. In this design, proposed by V. Stnotinit from Syzran, is, in my opinion, two significant drawbacks. The first is the complexity of manufacturing Cam: whenever it is not parallel two diameters cover will simply be cut. The second is that on the lid after use will appear uneven from the knife, and even after straightening it in most cases can get out of work slots when you edit, otherwise it will have to hold your finger, which is quite inconvenient.

The first thing to do is to replace the eccentric “universal” pen, as well as to complement the lower roller guide disk (with minimal indent on the thickness of the rectify cover).

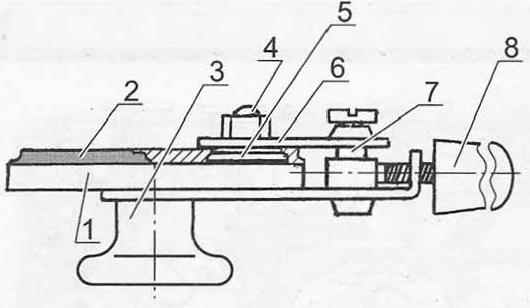

Fig. 1. Machine V. Stantine to edit the covers (“M-K” — 1 ’83):

1 — knob;

2, the lower roller;

3 — bearing (No. 1000900);

4 — axis;

5 —eccentric;

6 — top roller;

7 — roller cap;

8 — handle;

9 — the body of the fixture;

10 — screw clamps;

11 — cap banks.

The axis 4 (see Fig.1) width 5 mm should be increased up to 7 mm, as in figure 2; the rest is unchanged. However, the Assembly need not strictly follow that exactly matches the crest of the roller 6 and the return groove of the roller 2 (see Fig.1).

C. PLAMADEALA, D o n e C

In article V. Stamatina “Compotes — eternal cover” describes a device for straightening previously used lids for home canning.

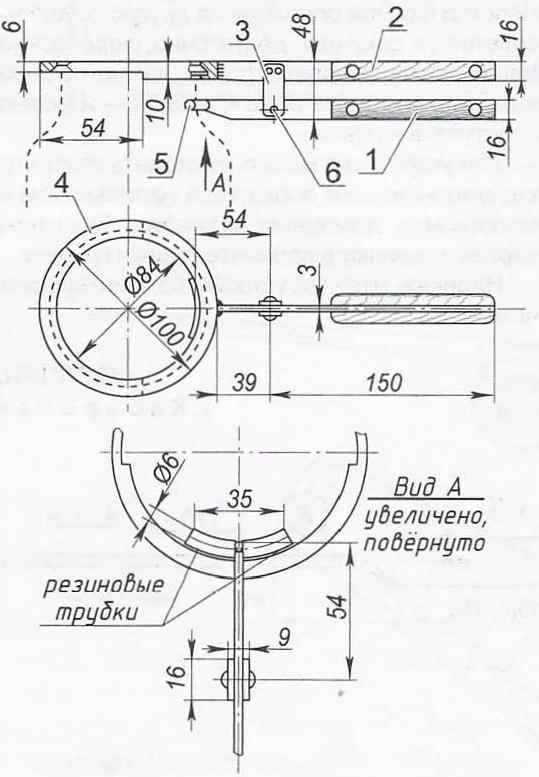

I made seaming machine is much easier on the basis of the factory. It took only the addition of parts thereto (one steel mounting plate 2.5 mm thick with two holes and one axis of a suitable bolt). Machine turned universal: she rolls, and rules used cover. The transition from one operation to another is accomplished in seconds: simply, turning machine, to move the roller on the mounting plate inside of the Cup with a lid and you are ready to edit.

Fig. 2. Modernization S. Plamadeala cars V. Stamatina (maintaining part position, which is shown in figure 1)

This device can be made to anyone who a little bit is file and a hammer at home. Send a drawing machine in the straightening of the covers.

I hope that my device will be of interest to readers.

P. RACIN, Khabarovsk

Order lids for canning become “eternal”, not necessarily the production of complex machines for their edits, proposed by V. Stuntin. Moreover, to make it not available to all: a lot of turning, plumbing, welding.

Fig. 3. Universal key P. Racine (industrial version) in the “edit cover”:

1 — body Cup (under cover);

2 — edge cap banks;

3 — handle;

4 — bolt-axle;

5 —regular seaming roller;

6 — mounting plate;

7 staff the roller axis;

8 — knob.

Enough to make offered me a key for gentle opening cans. It’s more affordable to manufacture and easy to operate. The main advantage of the key is that when opening cans it does not deform the cover surface, it is only slightly rolled up edge. After opening the key cover has little need to edit again ready for the next rolling. I am sure that the key will justify itself.

Fig. 4. Opener O. Petrenko:

1 — bottom (set) handle;

2 — top handle;

3 — jumper wire (2 PCs.);

4 — revealing the ring;

5 — rubber stop;

6 — hinge.

Details about the key did not tell, and to explain seems to be nothing. The design is very simple: two handles and a ring. Lower handle — squeezing relies on the Bank and its top ring is moved towards the lid, poddevat her and removes the banks.

O. PETRENKO, G. s g R a n