Perfectly round rubber gasket of any size or belt for the tape drive of the tape, you can cut from a sheet of rubber with this simple device. In addition, it can be used for cutting of large diameter holes in the plywood, plastic, plexiglass, cardboard and other similar materials.

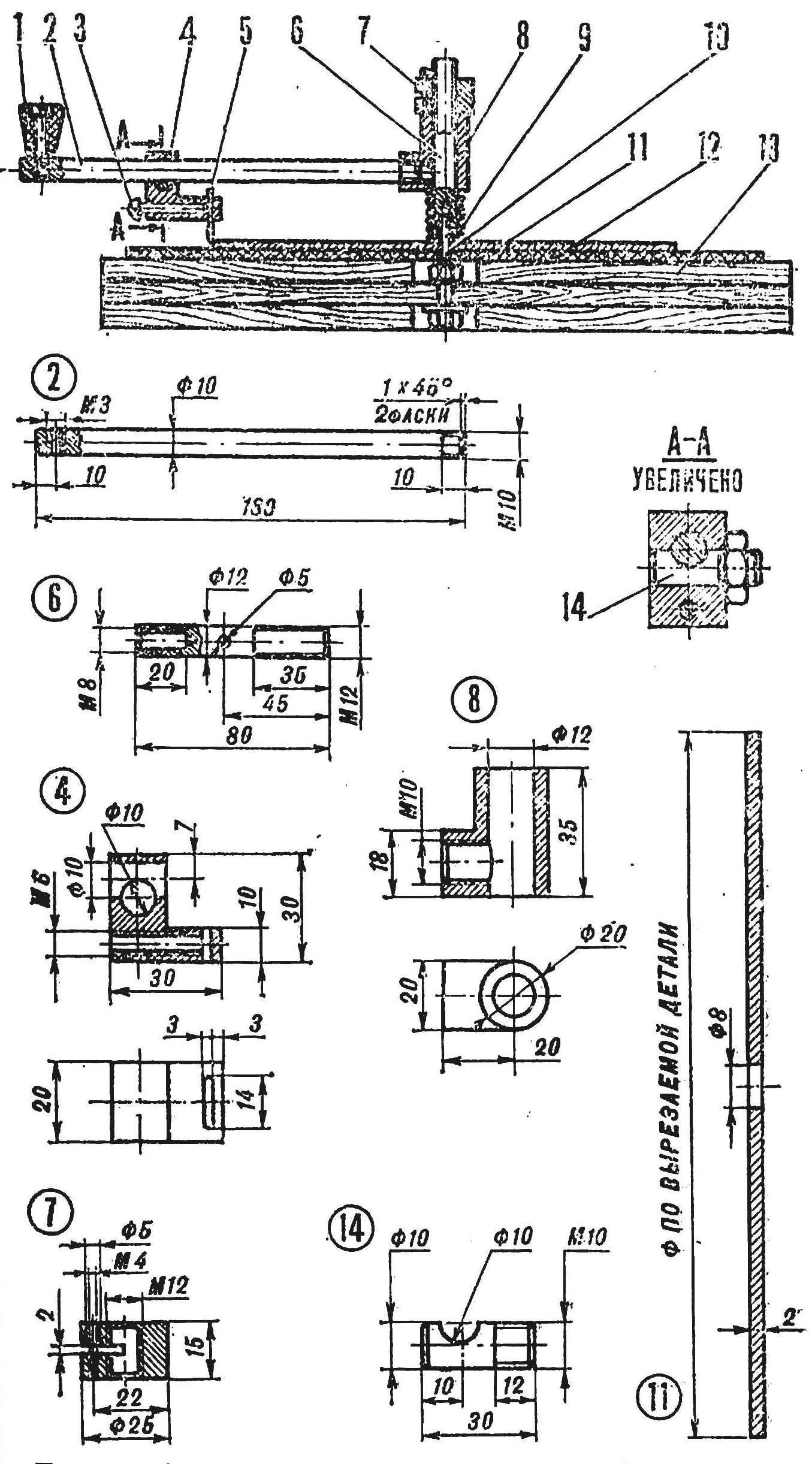

Perfectly round rubber gasket of any size or belt for the tape drive of the tape, you can cut from a sheet of rubber with this simple device. In addition, it can be used for cutting of large diameter holes in the plywood, plastic, plexiglass, cardboard and other similar materials. Make it yourself very easy. From a sheet of plywood 10 mm thick cut out three squares of size SOOH X300 mm. In the middle of one drill hole ø 8 mm and two 25 mm. d. of the workpiece, as shown in the drawing, will receive a fixture base. In the Central hole and secure with nut bolt M8.

The center column carved from brass rod d 12 mm and length 80 mm. Cut at one end of the external thread M12, end in the hole on the other side, internal M8.

The rotary sleeve has an axial bore d 12 mm and a perpendicular threaded M10.

Carrier is brass rod d 10 mm. At its one end tapped M10 with length 10 mm, and the radial M3 hole at the other end is made after the subassembly carrier with rotary sleeve: it must be parallel to its bore d 12 mm.

Slide in a corner is cut from dural bar. In its vertical wall are two holes d 10 mm — one under the carrier, and the second, perpendicular to it and shifted down by 5 mm, is to lock the threaded pin with a semicircular groove. In a horizontal wall propisyvaetsya groove cross section 14X3 mm — under the knife. Material for its manufacture is a chip of the saw blade. In the vertical groove of the slider knife is fixed by screw MB.

The retaining plate is cut on a lathe from metal plates with a thickness of 2 mm or thicker plastic sheet. The Central hole should be ø 8 mm and outer diameter is slightly less cut.

Lock nut sleeve with a Central M12 external thread has a 0 25 mm and height 15 mm. Saw in it a transverse groove on polumetra in this part make a longitudinal hole. Then the bottom half cut the M4 thread, and at the top — drill the full diameter up to ø 5 mm. Now pull the halves of the nut screw, thus you will be able to lock it in any position on the centre pillar.

Device for cutting large diameter holes:

1 — pen, 2 — led, 3 — M6 screw, 4 — slide, 5 — knife 6 — Central rack, 7 — lock nut 8 to the rotary sleeve 9 — spring 10 — bolt M8, 11 — retaining plate, 12 — blank,13 — base, 14 — threaded pin-locking.