Until recently, this metal and Assembly tool for screwing-unscrewing small fasteners and understand that special needs were not. Every Amateur designer or a mechanic, vehicle enthusiast, having in the Arsenal of his Studio a couple of sets of screwdrivers (under “slot” and by “cross”), they completely and treated. Head of cogs, bolts, screws in various household tools, appliances and even cars of domestic production, too, had, respectively, either slotted or Phillips working the nest.

Until recently, this metal and Assembly tool for screwing-unscrewing small fasteners and understand that special needs were not. Every Amateur designer or a mechanic, vehicle enthusiast, having in the Arsenal of his Studio a couple of sets of screwdrivers (under “slot” and by “cross”), they completely and treated. Head of cogs, bolts, screws in various household tools, appliances and even cars of domestic production, too, had, respectively, either slotted or Phillips working the nest.

Few people wonder about the reasons for this difference: first because it is designed primarily for use in manual Assembly of components and products, the second—when the installation is performed using mechanized tools (drill, screwdriver) because the “cross” was to allow for easy centering of the sting of the screwdriver relative to the slot. But these advantages of “cross” over “the slot”, perhaps, and exhausted. It is more “whimsical” when screwing: the excess of the axial forces (and without bias tool), threatens to “disrupt” the screw cutting, and reducing them leads to the expulsion stinger tool from the slot of the head with damage to his ribs and faces. Removing such fasteners are often the only possible “surgical” methods—for example, drilling, extraction (see “M-K” № 9’2003). In the case of the use of hardened screws, it is possible to ruin and the instrument itself.

To avoid such troubles, the craftsmen saws for cross slot and another slot. But this solution is not the best way out: after all, the head of the fastener thus significantly attenuated.

Imported home appliances and cars, rushed towards us in recent years, have fasteners not only with the usual heads. In their parts and mechanisms, now there are hardware that many before and never met. Tool for them, too, need an appropriate, and often special.

Important point. To determine the operating profile socket fasteners imported home appliances, you must also specify which system the metric or inch. Do not use a screwdriver one system for the other parts (with the exception of the universal tool). Especially important is the requirement for small fasteners, easy to damage from exposure is not an appropriate tool.

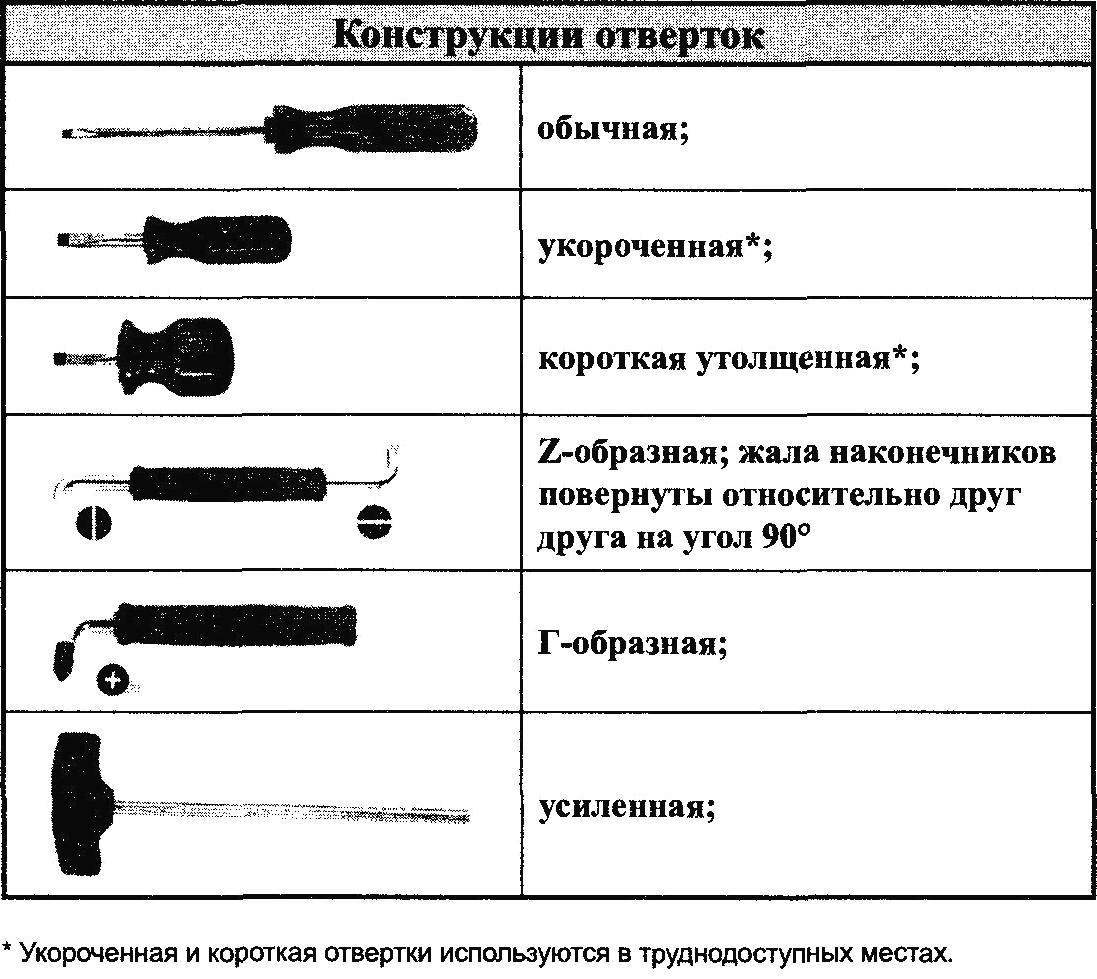

Different shape have not only a working socket head fasteners and ferrules (soldering tip) screwdriver, but the tool itself. Moreover, the changes of shapes and sizes for handles, and rods of tool. Screwdriver can be plain or reinforced, short or elongated, G – or Z-shaped. There is a universal screwdrivers in one handle needs fixed studs and is made in concert with them ferrules, or a single handle with a rod fixed different tips.

In addition, when a large volume of work and the use of centering fasteners or tool you can apply rotations and mechanized tools: impact wrenches, power drills.

It would be nice to get some advice.

Before starting work check the condition of the faces and edges of the slot. If they are crushed—the item is the best replacement.

Clean with a stiff brush nest from falling to the debris and degrease the surface lubricant here only hurts.

Do not try to loosen a fastener the wrong tool! Remember to spoil the nest is very easy to fix is impossible.

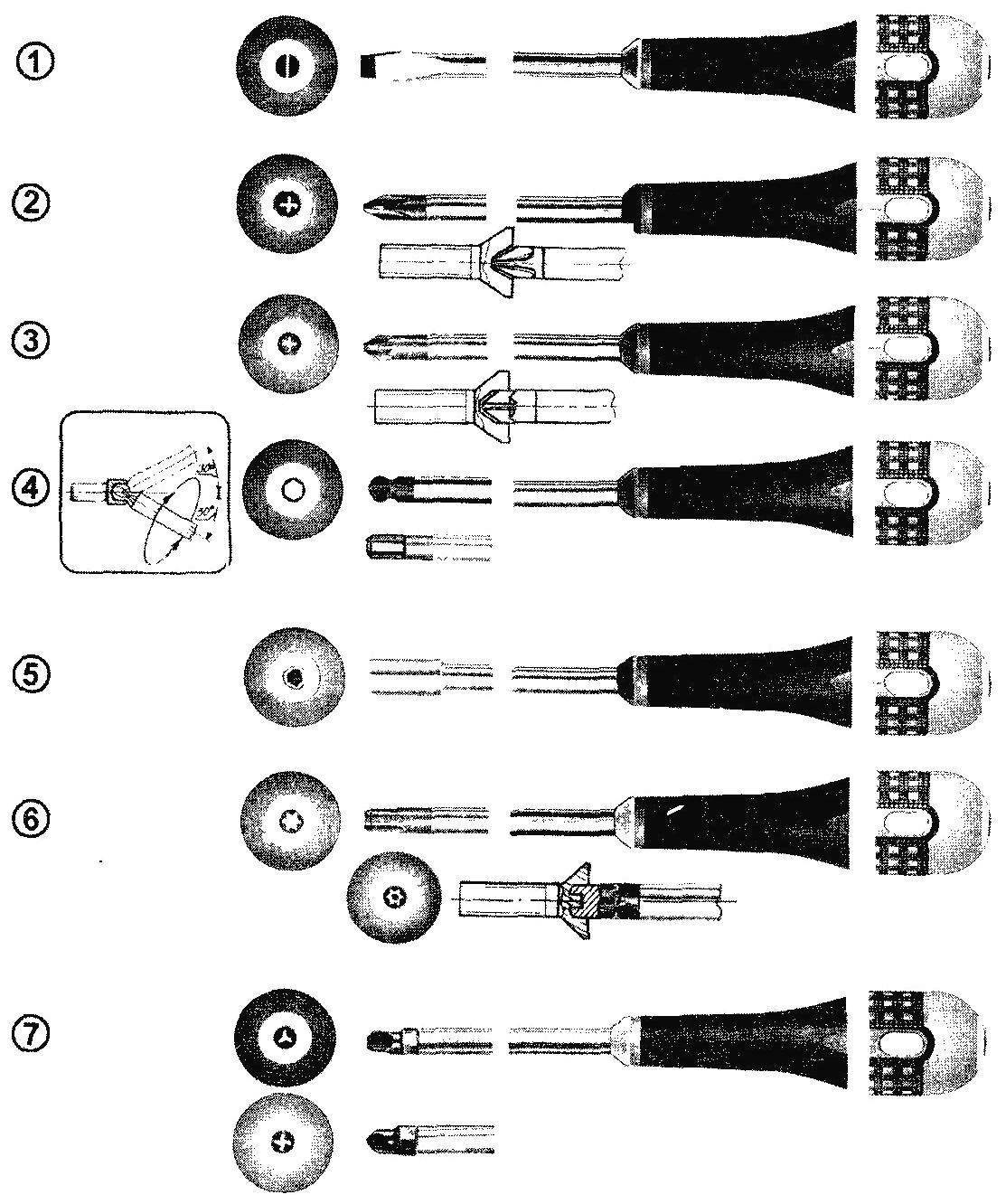

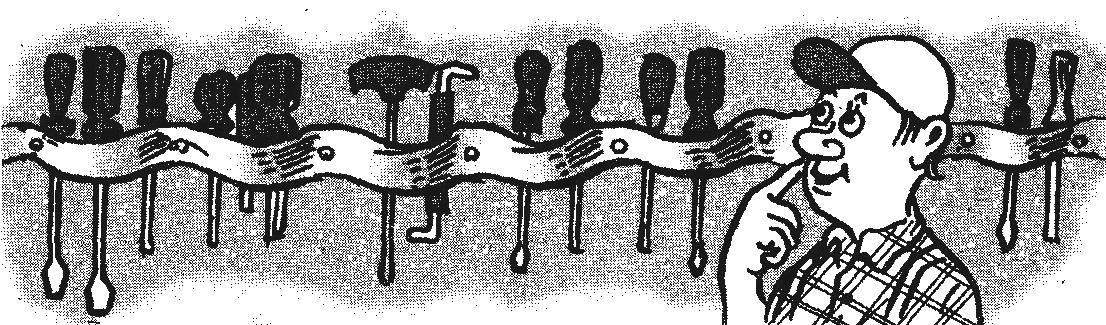

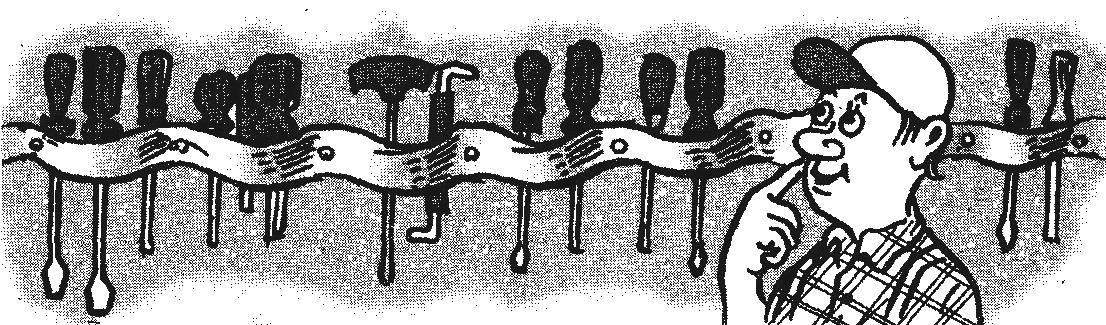

Forms of working socket head fasteners under the screwdriver

1. A straight groove is the most simple working socket head fasteners. Its disadvantage is not centers and does not fix the tool relative to the axis of the part. With parts that have a groove, it is difficult to work in hard-to-reach and unseen places. Dimensions stinger tip screwdriver (thickness x width) in mm: 0,3×1,5 to 3,0×18.

2.A simple “cross” “Philips” (Philips). The most common operating socket fasteners. The profile of the cut—cone or parabola. Centers the tool. Also has disadvantages: requires significant axial forces and does not “tolerate” bias tool. The diameter of the circumcircle of the sting from 2 to 10 mm.

3.A modified “cross” “Pozidriv” (Posidrive), with a deeper socket. Entry tool it is limited by the size of sting rays and a taper, and a special antennae. The tool is well centered relative to the fixture and firmly fixed in the nest, making it possible to increase the torque. Permits slight misalignment of the tool (within play). With the details that have such sockets, you can work a screwdriver with a simple cross, “Phillips”, but the benefits of “Positive” is not used.

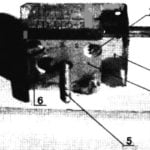

4.Internal hexagon Hexagon (Hexagon). Fasteners with the same socket in the head (before they were called “the machine”) are installed usually in hard to reach places or confined spaces. Tool amienties and after inserting into the socket is held in this little effort. Screwdriver with a rounded tip allows for working with skew up to 30°. Its maximum size “turnkey”, and as a screwdriver with a regular hexagon does not exceed 10 mm. Possible to work G-shaped hex key—then the nest can be up to 27 mm.

5.The outer hexagon is a common shape of the head fasteners. Often performed with the glide (along with extended washer). The socket is not in the details, and the tip of the screwdriver. This fixture is installed in easily accessible places. With these heads you can work and carob, and coupling keys. The hexagon has a screwdriver slot or socket.

6.International standards provide “star” socket. They have a different number of rays (5 to 12). Provide great torque with very little effort to hold the tool in the nest. Prevent unqualified intervention in critical or complex mechanisms. With the same purpose the socket may be performed with an axial pin. These fasteners and tools for them can be attributed to the special. Diameter of circumscribed circle of rays from this “star” sockets (and accordingly, the screwdriver bits) does not exceed 10 mm.

7.There is another special type of fasteners, which can be called “winged”. And not only because it is mainly used in critical nodes of the aircraft, but because his wings are made with a slight curve (like a bird’s wing). Bending allows you to easily wrap detail with a special screwdriver, but remove the detail even with this tool it is possible only with great effort of fixing. The socket may have three wings (abroad according to ISO, he was given the title Tri-Wing) or four (name—Torg-Set).

A. BURNAEV

Recommend to read

BABY GEAR

BABY GEAR

Searching for the correct gear for mechanisms of control model of the submarine I looked through descriptions of many designs with the aim to choose the most simple to manufacture. In... ON THE RACETRACK – THE “TADPOLE”

ON THE RACETRACK – THE “TADPOLE”

Although the car with the air screw (the cars) and are considered only a transitional step on the way of a young athlete from the "children" contour and rezinomotornaya of micromachines...

Until recently, this metal and Assembly tool for screwing-unscrewing small fasteners and understand that special needs were not. Every Amateur designer or a mechanic, vehicle enthusiast, having in the Arsenal of his Studio a couple of sets of screwdrivers (under “slot” and by “cross”), they completely and treated. Head of cogs, bolts, screws in various household tools, appliances and even cars of domestic production, too, had, respectively, either slotted or Phillips working the nest.

Until recently, this metal and Assembly tool for screwing-unscrewing small fasteners and understand that special needs were not. Every Amateur designer or a mechanic, vehicle enthusiast, having in the Arsenal of his Studio a couple of sets of screwdrivers (under “slot” and by “cross”), they completely and treated. Head of cogs, bolts, screws in various household tools, appliances and even cars of domestic production, too, had, respectively, either slotted or Phillips working the nest.