Arsenal machine tools home workshop, it is useful to fill up the circular saw. Pin CE on the workbench, next to the plumbing Vice, in which clamped the workpiece. Working tool saws — abrasive disk. He “tough” hardened to any hardness of steel rods, angles, pipes, sheets n even tiles, porcelain and glass, and the cut surface obtained is sufficiently clear. If you replace the disc with a saw with fine teeth, for cutting wood, plywood or plastic, diamond same drive will give the opportunity to handle the stones.

For clamping workpiece is convenient to use a rotary vise, in this case, cutting can be performed at an angle, which is useful for preparation of parts for welding.

Various adaptations to the saw allow you to do shallow cuts and grooves, and even turn it into a regular “circular saw”.

For this saw, you will need single-phase motor power 340 W (bench grinder) or three-phase type AOL 21-2 power of 400 W with a speed of 2800 Rev/min rotation is transferred to the spindle — wedge belt type A-1018 from GAZ-24.

The basis of the saw — spinal frame of square section, to which on one side is welded the spindle housing and on the other plate for engine mounting. A groove in the frame “missing pipe 1/2” — it is a case of the axis of swing of the saw. Performing welding operations, make sure that the axis of the motor shaft, the spindle shaft and the axis of swing of the saw was strictly parallel. After welding the frame be sure to mold, grind the welds and paint nitroemalyu with pre-primer.

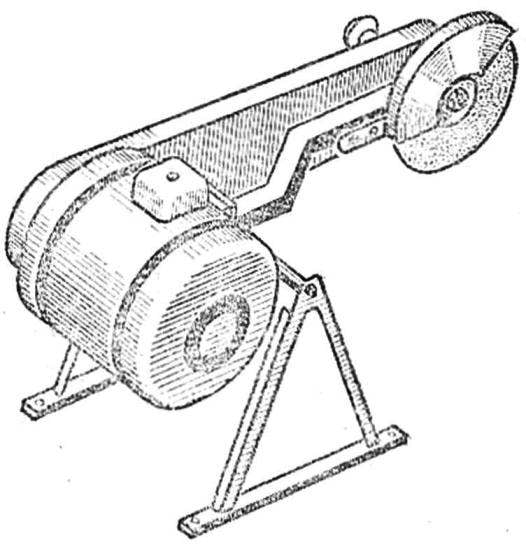

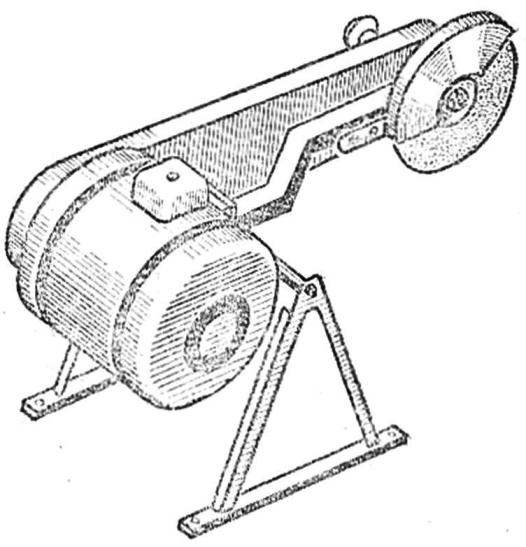

Pendulum saw:

1 — motor, 2 — pole, 3 — a protective casing of the tool. 4 tool (grinding wheel). 5 — toothed belt guard, 6 — clip And belt-1018, 7 — screw М8Х14 mm 8 — drive pulley (D 16), 9 — housing cover strap (steel), 10 — driven pulley (D 16). 11 — spacer (steel). 12 — washer (steel), 13 — arm pendulum feeder, 14 — bolt М6Х12 15 mm — screw M5 X10 mm, 16 — shaft (steel), 17 — a cover (D 16), the 18 — cap (D 16), 19 — Bush ‘(steel) 20 — washer (steel). 21 — nut (steel), 22 — ball bearing No. 203, 23 — case (steel), 24 — boss (steel), 25 mm screw М6Х8, 26 — screw M3 X 16 mm, 27 — boss (steel) 28 — frame (steel), 29 — a bolt М6Х16 mm, 30 — tube 1/2″ (steel), 31 — axis (steel), 32 — Bush (steel), 33-washer 34 — nut M10 35 — plate (steel) 36 is an intermediate case (D 16).

The main parts of the saw

Fit to the circular saw:

A — for cutting through grooves:

1 — a casing of a belt drive, 2 — bracket, 3 — Desk, mounted in a vise;

In, for cutting sheet material:

1 — a casing of a belt drive, 2 — folding table 3 — hinge, 4, 5 — brackets.

The cover belt and the casing of the abrasive disc of sheet steel in thickness of 2 mm. Welding preparation is better from the inside corner seam. The belt guard is attached with screws directly to the engine and frame to which is screwed the casing of the grinding wheel. The drive handle is located on the removable cover of the belt.

Spindle bearings before Assembly, fill with grease tsiatim-221. In the grooves of the bearing insert felt rings, impregnated with liquid lubricant.

Have collected the saw motor needs to move the spindle and located at the bottom, between the supports, otherwise in the moment when the saw blade abrasive may come in contact with the workpiece and to crumble.

When working on the pendulum saw it is necessary to strictly observe the safety rules. The power supply cable must be protected against mechanical damage steel flexible hose, which can take from shower hose. The motor and the saw itself must be grounded. The working tool is secured on the shaft only nut left-hand thread. To work with the saw without goggles is dangerous.

If the operation of the unit loosens the drive belt, it is necessary to pull what between the frame plate and the engine enough to make a plate of the required thickness.

ZAITSEV eigener-Konstruktor

Recommend to read ANYONE CAN MAKE AN AIRPLANE! Having once decided to build an airplane, the home-made man is faced with a number of questions, and the outcome of the whole matter depends on the answer to them. It seems to me that... THE PIPE DOES NOT COLLAPSE Thin-walled tube of soft metal when you try to bend often creased. To avoid this, they are usually pre-stuffed with sand. With the same purpose, you can use another method: navit on the...  Arsenal machine tools home workshop, it is useful to fill up the circular saw. Pin CE on the workbench, next to the plumbing Vice, in which clamped the workpiece. Working tool saws — abrasive disk. He “tough” hardened to any hardness of steel rods, angles, pipes, sheets n even tiles, porcelain and glass, and the cut surface obtained is sufficiently clear. If you replace the disc with a saw with fine teeth, for cutting wood, plywood or plastic, diamond same drive will give the opportunity to handle the stones.

Arsenal machine tools home workshop, it is useful to fill up the circular saw. Pin CE on the workbench, next to the plumbing Vice, in which clamped the workpiece. Working tool saws — abrasive disk. He “tough” hardened to any hardness of steel rods, angles, pipes, sheets n even tiles, porcelain and glass, and the cut surface obtained is sufficiently clear. If you replace the disc with a saw with fine teeth, for cutting wood, plywood or plastic, diamond same drive will give the opportunity to handle the stones.