Screws is heat treated (hardened, cemented, etc.) screws. Unlike the conventional which are mainly used in joinery for connecting wood elements, screws used for “non-critical” connections of various components (particularly cladding) with thin-walled steel base panels or brackets. The use of screws is expedient in cases when it is impossible to use bolt-on mounting hardware due to the fact that there is no access (or it is difficult) on the back side for nut installation. However, the screw-thread in the holes of the panels or brackets cut screws, often consists of one coil due to the small thickness of the underlying details. Therefore, the screws tight to wrap not (broken thread) and the connection is weak.

Screws is heat treated (hardened, cemented, etc.) screws. Unlike the conventional which are mainly used in joinery for connecting wood elements, screws used for “non-critical” connections of various components (particularly cladding) with thin-walled steel base panels or brackets. The use of screws is expedient in cases when it is impossible to use bolt-on mounting hardware due to the fact that there is no access (or it is difficult) on the back side for nut installation. However, the screw-thread in the holes of the panels or brackets cut screws, often consists of one coil due to the small thickness of the underlying details. Therefore, the screws tight to wrap not (broken thread) and the connection is weak.

To eliminate this drawback in order to more reliable bonding of the parts in the hole under the screw it is necessary not just to drill and pre-prepare a place for him to perform one additional operation.

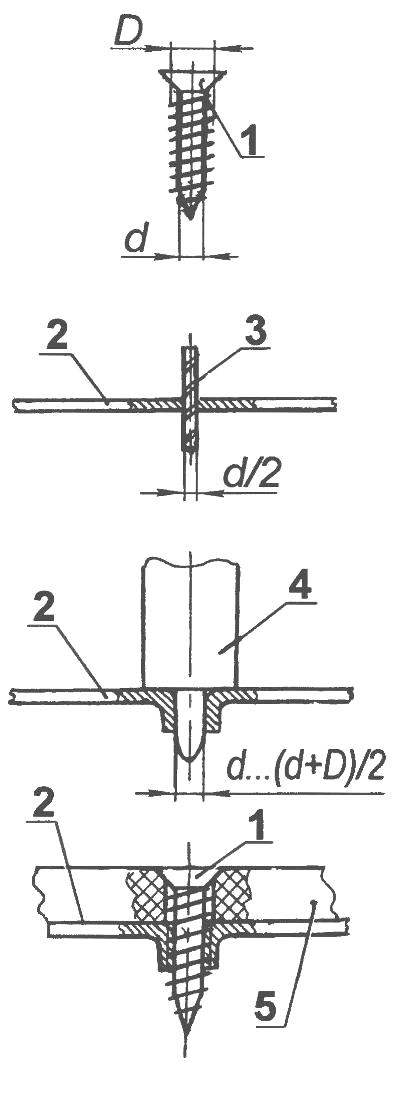

First at the metal sheet of the base panel, or a shelf bracket, as usual, drilled a hole under the screw. But its diameter should be not more than half of the diameter of the shank of the fastener, that is, d/2 (height of screw cutting is not considered). Then a blunt punch with a diameter of d (if sheet thickness is comparable to or larger than d) or with a diameter equal to (d + d)/2 (if the sheet thickness is less than d), carefully punch a hole, pulling and arching wall around it.

The sequence of manufacturing “pukli”:

1 — screw; 2 — thin-walled steel panel; 3 — drill diameter d/2; 4 — a bolt with a pointy tip with a diameter of d(d + d)/2; 5 — attachable to panel detail

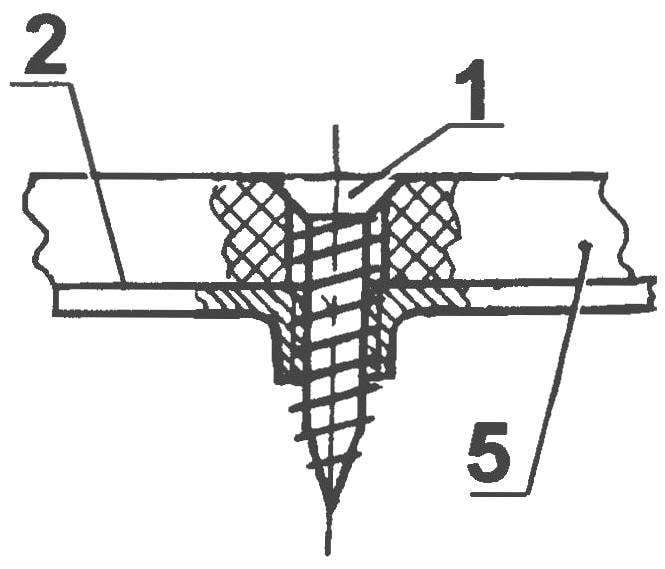

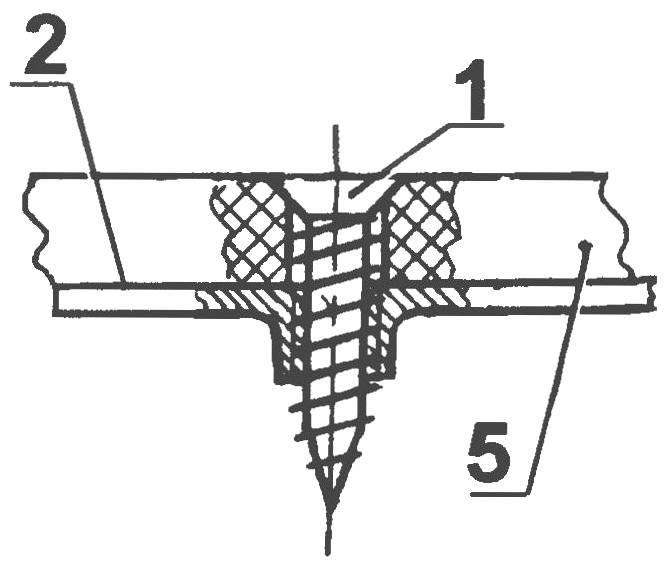

The result is a “UCLA” — hole with ribs. Now in the “Pallu” you can boldly screwing the screws and securely attach the item to the panel or bracket. By the way, in a “puckle” (if you will allow the thickness of the ribs) it is possible to cut a thread and screw detail screw.

A. somewhere behind the house Anna