When repairing machinery, especially agricultural, are quite common and at the same time melomakarouna operations cutting of sheet iron, and the manufacture of cardboard strips with holes. Often these works are performed with hand tools that does not provide neither the productivity nor quality.

When repairing machinery, especially agricultural, are quite common and at the same time melomakarouna operations cutting of sheet iron, and the manufacture of cardboard strips with holes. Often these works are performed with hand tools that does not provide neither the productivity nor quality.

Innovator V. Kosachev from Novgorod-Seversky district Association of Selkhoztekhnika Chernihiv region has set a goal to mechanize this work. He managed to create a universal mechanism capable of performing both operations, despite the fact that technologically they are quite heterogeneous. Made machine at the same time, and mechanical shears quickly and easily raskraivajutsja sheet metal, and the cutter, and a kind of “punch.” Due to the special knife and the second pneumatic working tool it can cut cardboard strips the necessary configuration and make holes in them. This greatly increases the efficiency of such a power tool, saves production area.

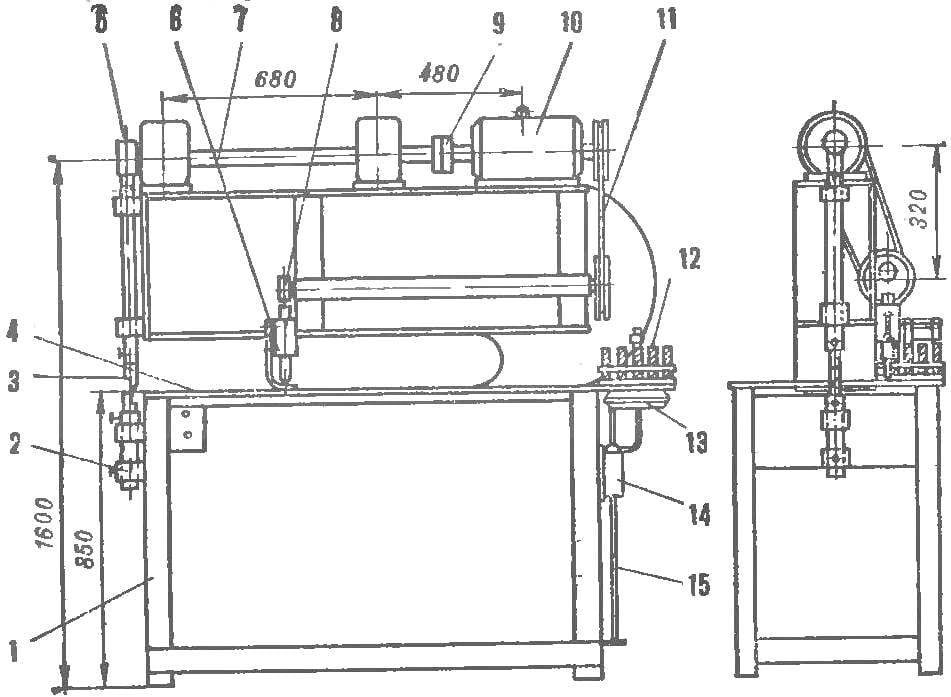

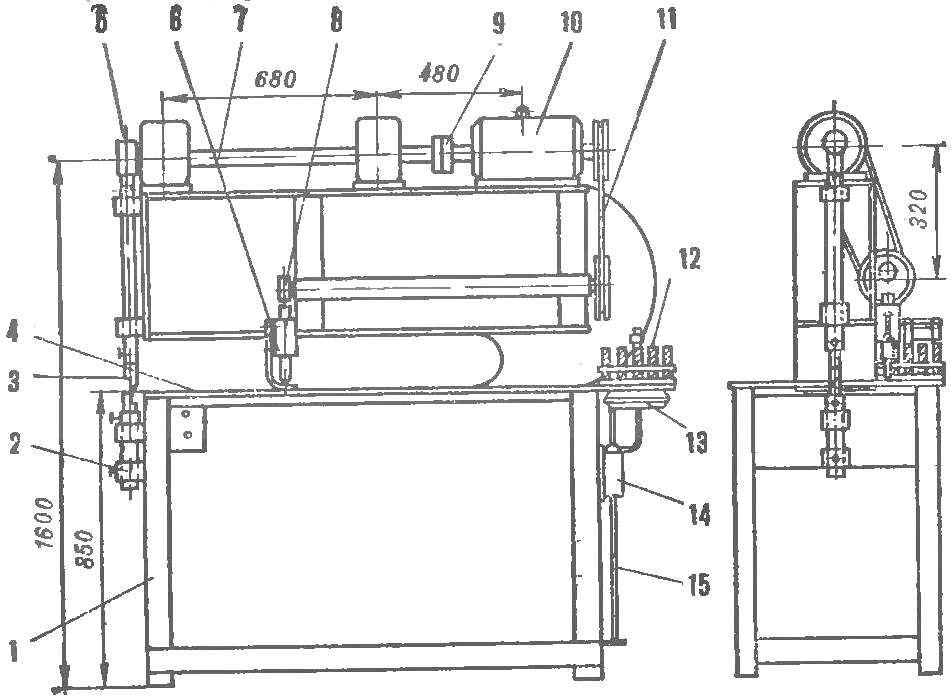

Shearing:

1 — frame, 2 — lower, fixed knife, 3 — upper, movable knife, 4 — table, 5 — yoke, 6 — cutter for cardboard, 7 — shaft, 8 — Cam, 9 — coupling, 10 — motor, 11 — V-belt drive, 12 — pneumatic press, 13 — a pneumatic chamber, 14 — pneumogram, 15 — thrust with foot pedal.

Shearing machine (see picture). represent the frame on which are mounted table and fixed knife. Over the table reinforced the motor, from which rotation through the coupling and shaft is transmitted to the crank and movable upper knife, reciprocating movement. Shears cut sheet metal thickness up to 3 mm.

Motor rotation is transmitted to the other shaft eccentric informing reciprocating motion of the other knife — cutter for face cutting of cardboard. As for cutting holes in cardboard strips on the machine there is a pneumatic press, consisting of pneumatic chambers, pneumogram and foot controls. In one press of the pedal is punching all the necessary holes.