The bearings are lubricated with petroleum jelly or Ciation.

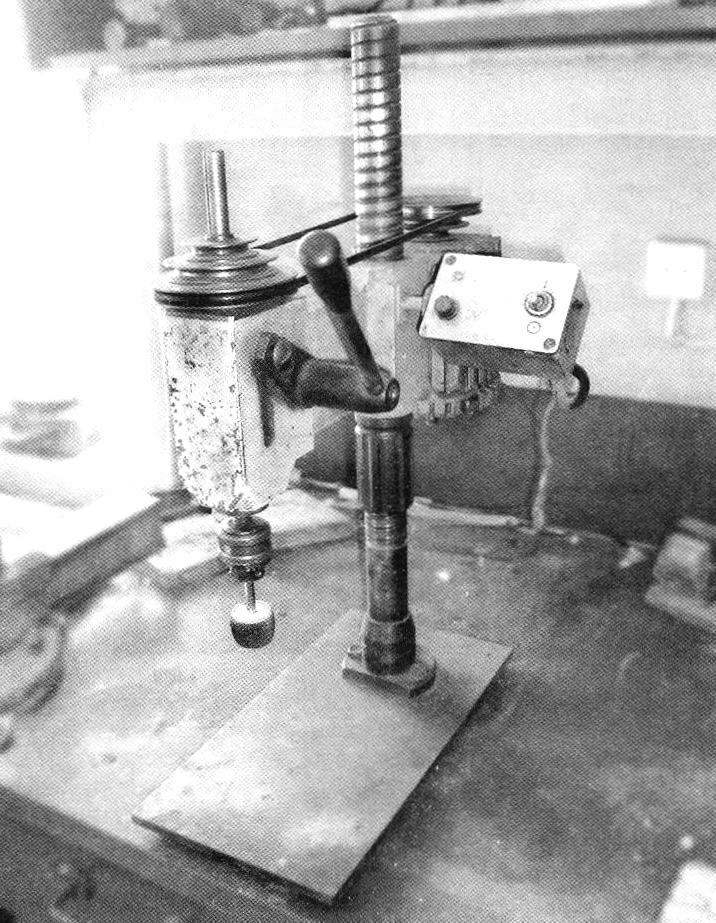

The motor selected is quite common, used in household appliances, CD — 50У4. It has capacity N=60 watts, rpm — 3000 per minute. The engine is mounted at three points sideways to the control panel. On this same panel is installed and the three-position switch.

Stand has a height of 300 mm — for drilling holes in small and oversized items that is enough. If the item is high, then process the console should be rotated 180 degrees, and the machine set on the edge of the table (bench) and fasten here a counterweight of an additional massive cargo or clamps.

To hold the console at a predetermined height at the front is a locking mechanism consisting of a clip, which is a half of the studs (or screw without head) M10 with a small cut on the diameter of the strut and the respective weld nuts with washer. The clip is installed in the blind hole of the console, and only a small threaded end comes out. The most curious is that not see how to work this site.

Fig. 3. The details of the mechanism toporek console:

1 —clip (steel 45, range 10); 2 — washer (St3, circle 20); 3—notched nut М10х 1

Fig. 4. Circuit diagram to connect the machine to a household mains

Handle feed is performed from a round steel rod, she pushed the handle of the dielectric. The handle is bent slightly to the side — this improves the overview and enhances the convenience of controlling a work tool. At the end of the handle drilled a hole for the axis with which it connects to the console. Axis — screw M6. In the middle part of the arm is a flat ground (both sides are run flats) and cut a long groove. Along the slot to move the body screw M6 screwed into the Cup of the spindle. By tightening this screw is the retaining Cup with the stem in the console, that is, the cartridge will not move — this is required when the flow need not be implemented by the tool and the workpiece.

About wiring the motor connections in a domestic network the magazine mentioned several times, and no difficulties in this matter. In addition, the motor housing reinforced plate connecting it to the network 220V. But in the scheme of the proposed drill has its own characteristics. For example, it includes a led diode, signaling willingness to work. The machine is equipped with a backlight with a reflector, attached to the side of the console (not shown) which turn on simultaneously and in conjunction with an electric motor, a three position switch (toggle switch with neutral position) to enable the reverse. Additional lighting in the work area significantly affects the quality of the work, especially when drilling holes of small diameter.

To make the machine aesthetic appearance it needs to be painted. Color according to your taste and to avoid water stains, it is advisable to do a risograph. Don’t paint only the front, the glass of the spindle and the outer surface of the table.

This product faithfully for the first year serves me in the shop. All of which repeated the design I wish you success in work!

I. ROSTOV, mechanical engineer, p. Sazonovo-1, Vologda region

Recommend to read

Pendulum saw

Pendulum saw

It's useful to supplement the arsenal of metal-cutting machines in a home workshop with a pendulum saw. It can be mounted on a workbench, next to bench vises, in which the workpiece to be... BOAT-CLAMSHELL

BOAT-CLAMSHELL

Propose the layout diagram of the folding kayak with a rigid hull or a light boat in the yard, It consists of middle main part and two detachable sections — bow and stern, the kayak is...

In the journal “modelist-Konstruktor” No. 4 for 2008 have already been published, one of my small bench drill press. Now offers readers a different, in my opinion, a more versatile and interesting design. Meanwhile, this upright drilling machines single-spindle work hard also not hard to make yourself, having practical skills in machining metal parts and metal build, and some of the most complex parts can be ordered as a master-technician.

In the journal “modelist-Konstruktor” No. 4 for 2008 have already been published, one of my small bench drill press. Now offers readers a different, in my opinion, a more versatile and interesting design. Meanwhile, this upright drilling machines single-spindle work hard also not hard to make yourself, having practical skills in machining metal parts and metal build, and some of the most complex parts can be ordered as a master-technician.