When constructing or repairing equipment, domestic equipment in front of home masters are often faced with the problem: how to cook certain items? Buy a welding machine is not quite simple, and you can do it yourself…

In this issue we introduce the readers with simple homemade welding machine — the Central exhibit of the exhibition NTTM-87. Made according to the original circuit, it is protected by a certificate of rationalization proposal at the pilot plant of VNIIGAZ.

Welding machine works on 220 V and has high electrical characteristics. Thanks to the use of a new form of magnetic device weight is only 9 kg with overall dimensions of 125X150 mm. This is achieved using a transformer iron rod, the rolled in the shape of a torus, instead of the traditional package W-shaped plates. Electrical characteristics of the transformer tor magnetic core is approximately 5 times higher than that of the W-shaped and minimal electrical losses.

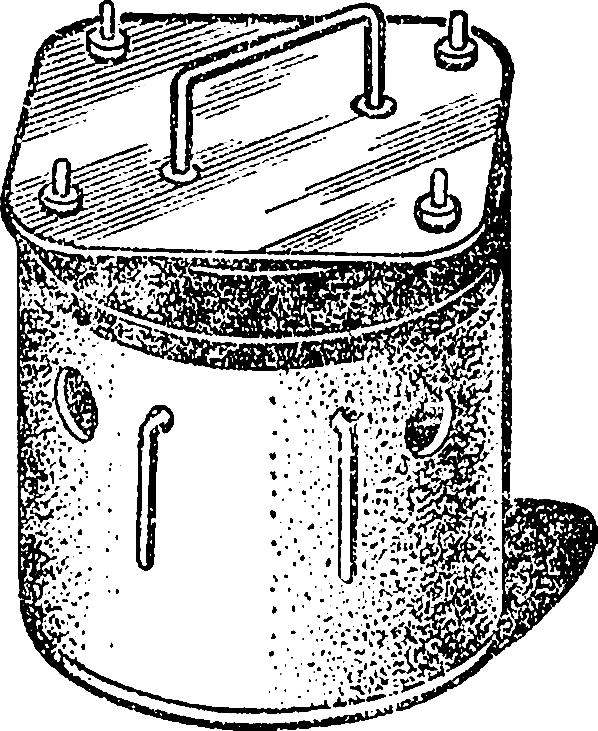

Fig. 1. Welder-boy.

To get rid of searches transformer iron deficient, you can buy in the store ready “Latr” on 9 And or use a magnetic torus of the burned laboratory transformer. To do this, remove the fence, rebar and remove the burnt coil. Released the magnetic circuit must be isolated from the future of winding layers of insulation or two layers of varnished cloth.

Fig. 2. Transformer welding machine:

1 — primary winding 2 and secondary winding 3 — Bay wires, 4 — yoke.

Welding transformer has two separate windings. Applied in the primary wire of PEV-2 Ø 1.2 mm, length 170 m. For convenience, you can use a Shuttle (a wooden rail 50X50 mm with slots on the ends), which is pre-wound around the whole cable. Between the windings placed a layer of insulation. Secondary winding — copper wire or glassy cotton insulation has 45 turns over primary. Inside a wire coil to a coil, and outside, with a small gap for the uniform arrangement and better cooling.

Fig. 3. The electrical circuit of the welding machine.

Work easier to perform together: one carefully, not touching for adjacent turns, so as not to damage the insulation, stretches and puts the wire, and the assistant holds the free end, preventing it from twisting. Welding transformer, made in this way will give the current 80-185 A.

If you purchased a “Latr” on the 9th and during the inspection it was found that its winding is intact, the case is much simpler. Using the coil as the primary, possible for 1 hour to collect the welding transformer giving a current of 70-150 A. For this it is necessary to remove the fence, slip the slider and the fastening fittings. Then determine and mark the findings on 220, and the other ends securely Seitalieva temporarily pressed against the yoke so as not to damage them when working with the secondary winding. Installation last is the same as in the previous embodiment, using the copper wire of the same cross section and length.

The assembled transformer is placed in an isolated area in old housing, pre-drilled holes in it for ventilation. The wires of the primary winding are connected to the network 220 V cable SRPS or GRP; the circuit is necessary to provide cut-off machine AP-25. The terminals of the secondary winding is connected to the flexible insulated wires PSG, one of which is fixed to the electrode holder and the other weldment. This same wire for the safety of the welder is grounded.

Current adjustment is provided for inclusion in series in the circuit of the wire electrode holder of ballistica — konstantinovoj or nichrome wire Ø 3 mm and length 5 m, coiled “snake”, which is attached to asbestos cement sheet. All the wiring and ballastnika — with bolts M10. The method of selection by moving the “snake” the attachment point of the wire, set the required current. The variant of the control voltage using electrodes of different diameter. Used for welding electrodes type e-5РА UONII-13/55 — 2,0-UD1 Ø 1-3 mm.

All necessary materials for the welding transformer can be purchased in the trading network. A person familiar with electrical engineering, to make such a device is not difficult.

When working to avoid burns, you must apply fiberboard guard is provided with a filter, e-1, e-2. Mandatory headgear, overalls and gloves. The welding machine should be protected from moisture and prevent it from overheating. The indicative mode electrode Ø 3 mm: for transformer with current 80-185 A — 10 electrodes and with a current of 70-150 A — 3 electrode; after which the unit must be disconnected from the network for at least 5 minutes.

B. SOKOLOV, engineer, laureate of the all wheel drive NTTM-87

Recommend to read BEE CLINIC One of the most dangerous and contagious diseases of bees — varroa. It is called mite, parasitic on the bee larvae and pupae. To deal with it, bee colonies were treated with a solution... PIPE IS NOT A HINDRANCE If the kitchen in your apartment there is a ledge or water pipes, interfere with the hanging shelves, modify them in accordance with a pattern.  When constructing or repairing equipment, domestic equipment in front of home masters are often faced with the problem: how to cook certain items? Buy a welding machine is not quite simple, and you can do it yourself…

When constructing or repairing equipment, domestic equipment in front of home masters are often faced with the problem: how to cook certain items? Buy a welding machine is not quite simple, and you can do it yourself…