The management of these sleds is somewhat reminiscent of airplane: it also consists of the pedals and handles. The direction of the descent is aged using the pedals, and the handle is used for braking.

The management of these sleds is somewhat reminiscent of airplane: it also consists of the pedals and handles. The direction of the descent is aged using the pedals, and the handle is used for braking.

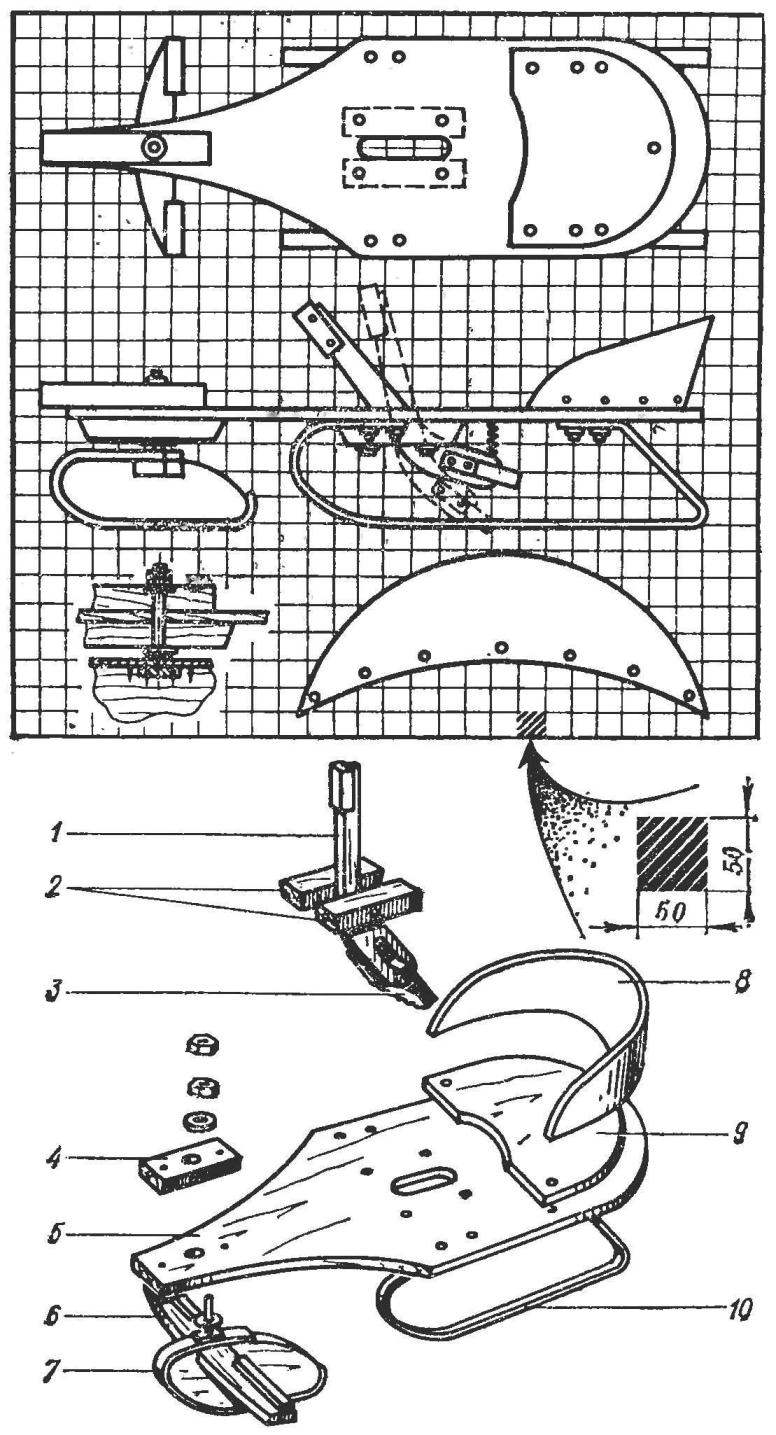

The base of the sled is made from a sheet of plywood with a thickness of about 15 mm or from a joiner’s plate with dimensions of 400 X 1200 mm In accordance with a pattern cut out the slot for the brake lever. Its bearings are two beech bar that is attached from the lower side of the base with screws and carpenter’s glue.

Brake lever cut out Of two plywood sheets glued together with Total thickness of about 20 mm. In its bottom part secured the plywood plate 10 mm thickness.

The design of the sleigh:

1 — brake handle 2 — bearings of the brake lever 3 to the brake plate, 4 — bearing managed slideway (beech), 5 — base, 6 — foot controls, 7 — front runner, 8 seat, 9 seat, 10 rear skid.

Front steering skid is cut out from boards with a thickness of 20 mm and is enclosed with steel or duralumin band section 3X20 mm. In propyl of Poloz inserted a wooden rake — pedal control of the sled. The axis of rotation can be made from a bolt with thread M10.

The rear rails are bent from steel strip section 4X25 mm, and each attached to the base with four bolts Ø 6 mm. the Seat is cut from a joiner’s plate with a thickness of 16-20 mm, its back is made of plywood thickness of 4 mm.

That’s the whole design. Simple, isn’t it?