In Moscow last year in the framework of the “Moscow courtyard” is an accomplishment of territories near houses: broken rekultiviruemye new or old lawns, flower beds, public gardens, installed gazebo and just benches, decorating, sports and children’s playgrounds. Among the latter the most common, but there are unusual complexes with groups of figures based on folk tales. However, even for typical playgrounds are mounted separate simple but fun game structures. One of these and is offered to our readers.

In Moscow last year in the framework of the “Moscow courtyard” is an accomplishment of territories near houses: broken rekultiviruemye new or old lawns, flower beds, public gardens, installed gazebo and just benches, decorating, sports and children’s playgrounds. Among the latter the most common, but there are unusual complexes with groups of figures based on folk tales. However, even for typical playgrounds are mounted separate simple but fun game structures. One of these and is offered to our readers.

Each child’s parents read a fairy tale in verse by p. P. Yershov “the humpbacked Horse”, and children are familiar with this cute thing. But your child can even “ride” on it, if the Pope will undertake to make the horse-a rocking chair and set it in the yard or garden.

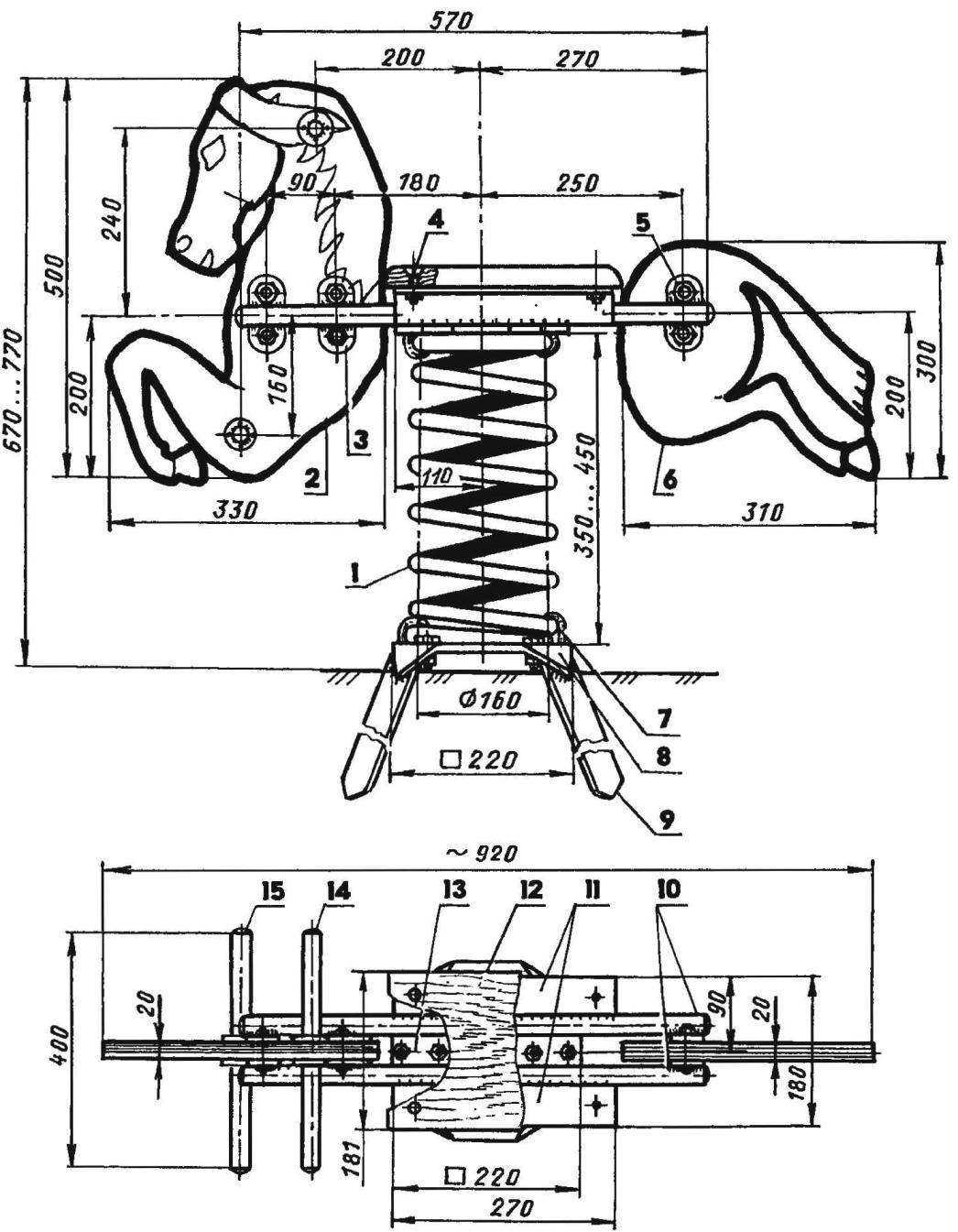

Design the rocking chair is simple, and to make it possible for everyone who knows how to hold the instrument. The welding operation (if there is no machine or experience in the production of such works) may be assigned to or performed using the so-called cold welding (to connect the parts using composite materials); finally, simply replace the welded connection of threaded parts.

The construction — spring from the front suspension of the truck of small or medium tonnage (GAZ, ZIL, etc.). You can use car two springs by screwing one into the other.

At a free length of the springs, 350-450 mm. the Top and bottom of the spring is attached to the supporting square plate of steel 5-mm sheet. The dimensions of the plates are the same — 220×220 mm, only the upper corners cut off and so it turned out regular octagon, and at the bottom they just bent downwards at an angle of about 60°.

Form wooden details and methods of mounting can vary, maintaining the strength and safety of the swing

To the upper plate is welded to the console — two pipe sections with a diameter of 3/4″ and a couple of racks of parts of 50×50 mm. Angles are the basis of wood (from the Board-“thirty”) of the saddle to which it is attached by M4 screws with countersunk heads. The dimensions of the seat such that they overlap the upper shelf of the parts is 3-5 mm on each side. In the absence of welding instead of angles to the plates by bolts M6 mounted shelves of channels in the same room. The middle parts (of channels), and hence the centre of the seat offset from the axis of the spring back a little. To each tube is welded in three oval pads — two in the front part for fastening of the “torso” and one to the rear end for mounting “groats”.

“Rump” and “torso” is made from 20 mm plywood (can be from parklea several layers of thinner), and they are cut only along the contour. The inner “emptiness” for the strength of the component parts (“legs”) I did not drink, but only drawn in contrasting colors (relative to main). All wooden parts are covered with oil paint, as a rocking-horse is in the yard winter and summer. Before painting all the corners and edges are rounded and sanded carefully. From the metal parts before they are coated everywhere chamfering. The ends of the tubes are closed with plastic plugs — the champagne corks.

Design rocking:

1 — spring (from the front suspension of the truck); 2 — “torso” (plywood s20); 3 — plate (steel, sheet s3, 6 PCs); 4 — bolt M4 flat head screws (4 PCs); 5 — stud M6 acorn nut (12 PCs); 6 — “rump” (plywood s20); 7 — ladder with pairs of M10 nuts and lock nuts (4 PCs.); 8 — lower skid plate (steel, sheet s5); 9 — pile (steel, strip 80×10, L600, 4 pieces); 10 shell; 11 — shelf cradle saddle (steel, angle 50×50, 2); 12 — saddle (Board s30); 13 — upper support plate (steel, sheet s5); 14 — “bridle” (pipe 1/2″); 15 — stirrups (pipe 1/2″)

Plywood plate “torso” and “rump” inserted between the plates of the consoles and fixed studs M6 with cap nuts (if these are not there, you can replace usual, but then the protruding threaded ends of the spikes should be cut with a file flush with the surfaces of the nuts). Then on the “torso” found: in the upper part — “bridle” at the bottom — “stirrups”. They are made of pipe segments with a diameter of 1/2″ and attached to the “torso” through the sharp lining with countersunk screws. One plate is welded to the segment tube is indented from its middle 10 mm (before installation) and the other after installing the “frenulum” or “stirrup” in the short seams, so as not to burn the plywood thoroughly welded metal.

And the last — set rocking on the Foundation. Classic version — recessed monolithic concrete column with anchor bolts. Another, more simple (but less reliable) — recessed plates-pins. Pins it is better to score not vertically, but at an angle of about 30-40° to the vertical in the corners of the bottom support plate and weld them to the protruding ends of the bent the corners of the plate. If the rocking chair is removable, welded joints are replaced with M10 bolt, which in both parts simultaneously drilled the appropriate holes.

A. POLIBIN