A painting works it is better to perform a “brush” made of foam. You can just stick a piece of foam to the wooden handle. However, we recommend you to make a special holder that gives the brush flexibility.

A painting works it is better to perform a “brush” made of foam. You can just stick a piece of foam to the wooden handle. However, we recommend you to make a special holder that gives the brush flexibility.

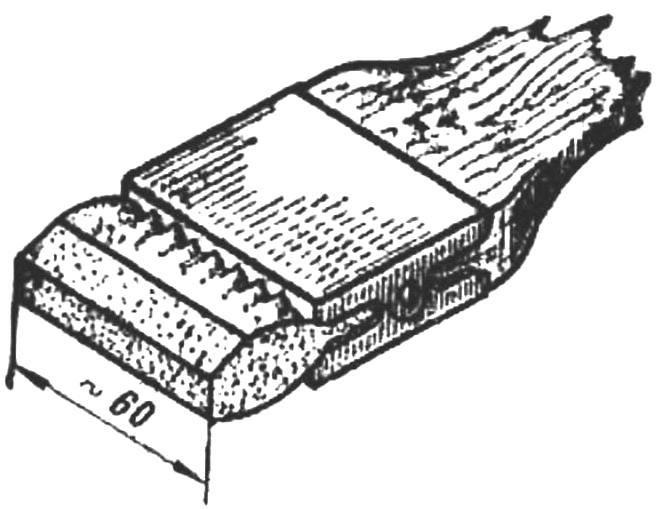

This will require two pieces of sheet metal with dimensions of 100 X 60 mm each with a thickness of 0.5—0.6 mm; wood block size 150X60X20 mm and one nail.

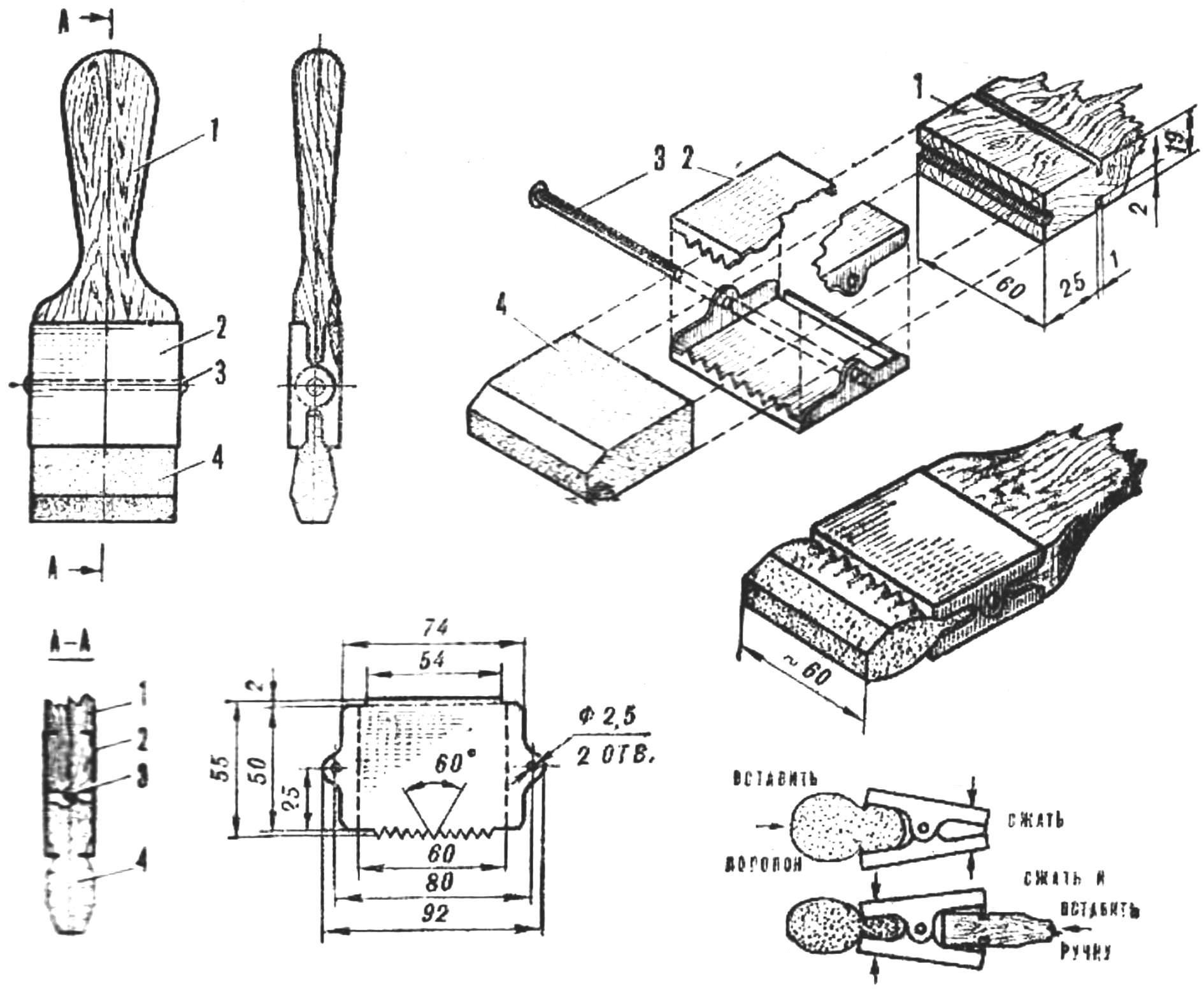

A wooden block cut out of the handle 1 convenient form cross groove — slots, as shown in the figure.

From tin, cut two cheeks workpiece holder 2, a scan of which is shown in the figure. The teeth and the edge of the blank is folded on the dashed lines in the same direction at right angles to the plane of the workpiece. The thus obtained two cheeks are interconnected by the hinge, passing through them, the nail, which will serve as axis 3. The protruding end of the nail should be cut, leaving 2-3 mm to rasclaat. Cheeks finished the cage must be easy to rotate around its axis.

Between the teeth of the clips is inserted a piece of foam that will serve as a working part of the brush.

Foam brush:

1 — the handle; 2 — cheek clips; 3 — axis holders; 4 — foam.

For fixing the clips with the foam on the handle needs to be done next. Squeeze your cheeks clips, pressing the prongs in inserted in between the foam. While on the opposite side of lip cheeks slightly spread, letting the pen in the clip all the way into the axle. Now release the clip, and due to the springy properties of the foam lip will be included in the cross Spitz of the handle, providing a secure fit.

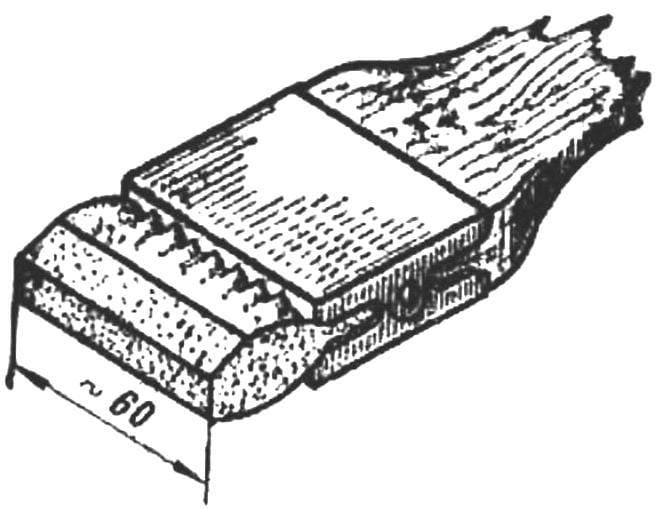

The brush does not need to wash, because after the work was easier to throw out soiled paint the foam and replace it with a new one. When you” than it can be given a different shape in accordance with the profile of the painted surface: for example, when painting pipe brush easy to make concave.

Of course, a foam brush can be any size, however, the reported figure was in practice the most convenient.

V. GOLD, mechanical engineer, Rostov-on-don