Each individual Builder wants his house was not only beautiful it’s durable, but cheap. Design and materials of the walls is about a third of all costs. Is there the possibility of saving? I propose to make the wall monolithic, lightweight concrete-filled; the role of the formwork perform asbestos-cement sheets, they also then have to serve as a lining. The cost of these walls is lower than the brick, and the use of lightweight aggregates (sawdust, slag, reed) will improve their thermal insulation properties. In addition, they can be more subtle and light. In the end, will reduce transport and construction costs.

Each individual Builder wants his house was not only beautiful it’s durable, but cheap. Design and materials of the walls is about a third of all costs. Is there the possibility of saving? I propose to make the wall monolithic, lightweight concrete-filled; the role of the formwork perform asbestos-cement sheets, they also then have to serve as a lining. The cost of these walls is lower than the brick, and the use of lightweight aggregates (sawdust, slag, reed) will improve their thermal insulation properties. In addition, they can be more subtle and light. In the end, will reduce transport and construction costs.

The use of a casing of asbestos cement sheets accelerates construction by eliminating the need for time-consuming operations such as plastering. Monolithic wall work durable, have high strength, not afraid of moisture, is practically fireproof.

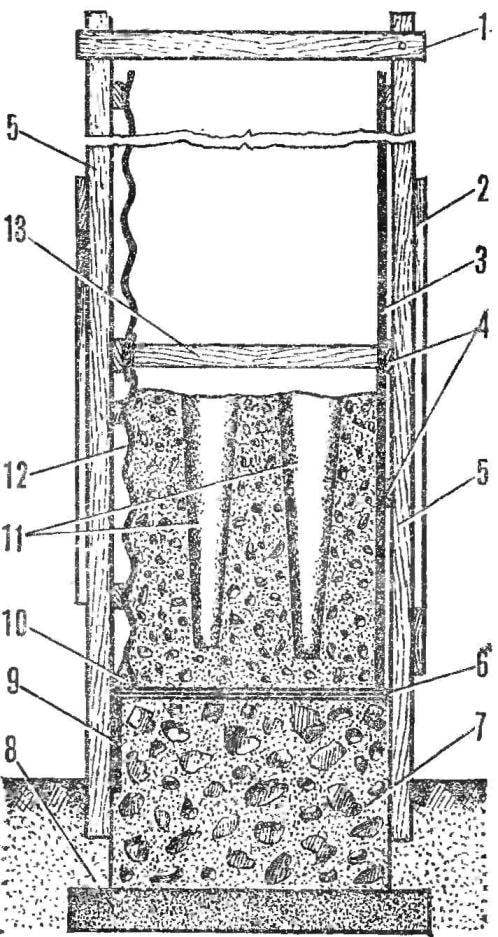

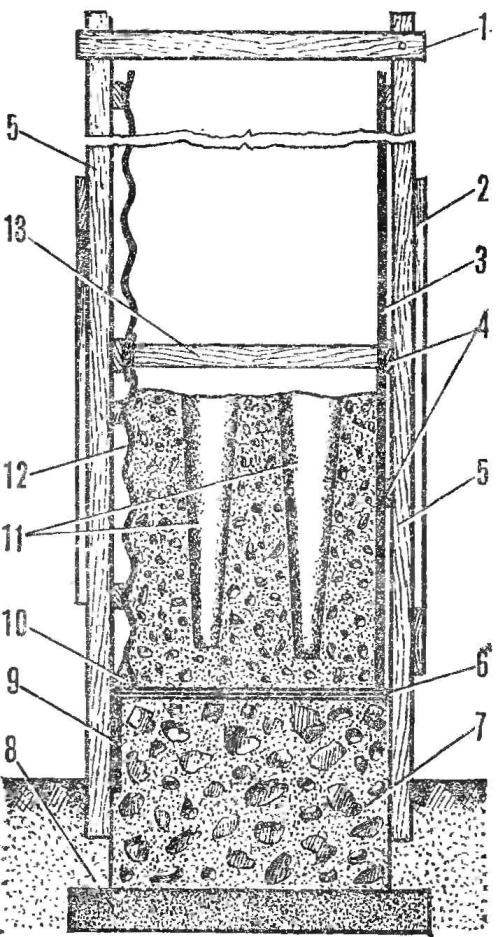

The forming of the walls begin with installation at the perimeter of the Foundation with vertical rods — wooden racks of a skeleton. The distance between them depends on the thickness of the uprights and horizontal sheathing material for fixing asbestos cement sheets. Between adjacent racks are fixed with struts. The upper ends of their associated horizontal bars.

On the front side on the base, retreating from the outer edge 30-40 mm, put provalnosti or wavy sheets of outer lining with overlapping at the half-wave. They attach to the crate, previously tightly fit to the base.

From the inside hung a flat plate inner lining. In contrast to the outer attach them back to back, trying to get a tight seam and smooth surface. Between the plates and racks insert temporary spacers; filling a space between the wall concrete mixture they removed.