The washing machine is firmly part of our everyday life and are today, an indicator not so much of prestige, as comfort and economy of effort. But if in cities, the connection of washing machines will not cause problems, in rural areas, where water supply is carried out on the columns and wells, to connect a washing machine much more difficult. And this complexity is mainly caused by a lack of pressure in the water circuit. Generally, washing machines are designed to work with the pressure of the incoming water 0,5-10 bar, and to provide such pressure can only be a forcing pump, or it is based on operating a water station (the latter can be bought at the price of 5000 rubles). Usually rural water supply washing machines provide as follows: above the washing machine barrel set volume of 50 – 200 l, from which by means of hoses, valves and adapters water comes into the machine by gravity. But this pressure for normal operation of the machine is not enough. The water passing through the built-in washing machine solenoid inlet valve (2 PCs.), filter and valve, is fed to the tank so slowly (literally drop by drop) that the Laundry can take several days. Who can afford such a unproductive waste of time?

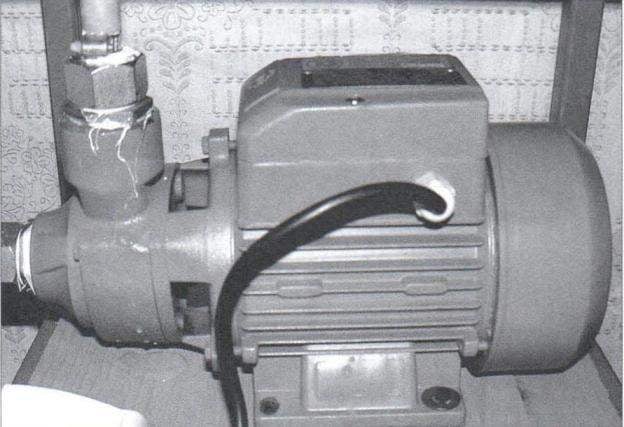

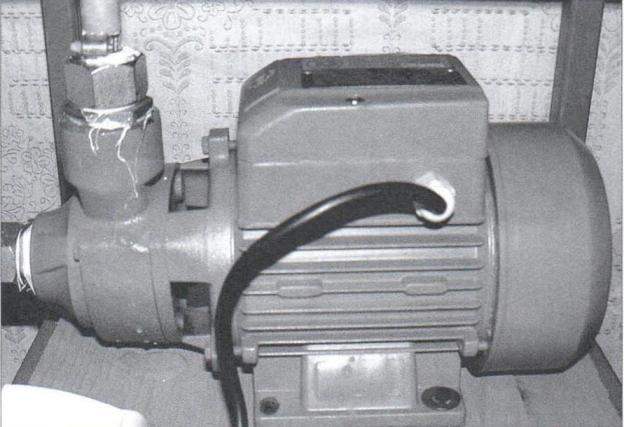

Connected centrifugal pump brand NBC-0,37

Inlet solenoid valve for washing machine

Look for a washing machine with the cover removed from the connected terminal block

In addition, “smart” filling washing machines do not understand such an attitude, takes a slow vodootvedenie as the complete absence of water in the system and stops the wash.

But our people are hard to scare and craftsmen have come up with a simple way to plug in the gap fill hose washing machine vidanagamage pump. And for this purpose you can apply almost any type of pump, whether submersible, centrifugal or vibrating appliances. They will create the minimum required for washing machine water pressure in the incoming circuit. Here preferences can differ on which pump to choose from: submersible or vibration have to drop into the barrel, the centrifugal sucks water from the hose and releases it through a hose. Prices at the pumps also vary from 1100 to 4200 rubles. I used the centrifugal household brand NBC-0,37, since the cost is very reasonable and the pump is conveniently built into the staffing gap fill hose washing machine.

Craftsmen connected the pump to the network 220 via a regular household lighting switch. Assuming that when the machine “asks for water”, you have to press the light switch and water at the desired pressure, sufficient for a washing machine, available in drum and tank.

But this raises two other questions. First – how to know when she “asks for water”, after all, turn on the pump (be it anything reliable) when closed, the output hole is impossible – there can be an imminent failure. After all a closed inlet valve of the washing machine when it is not in need of water, will mimic the situation “scored” outlet.

The second question is even more relevant: because normal washing machine (up to 20 000 RUB) few times “requires” the water in the wash cycle, and then, depending on the set mode, at least two times rinse cycle (while also pouring water parts), do not have any mistress relentlessly to herd my washing machine, at the right time to nourish it with the water?

Unfortunately, I have to. The stories of the inhabitants of rural areas, so do many who do not have in the household water stations (giving the pressure as a regular city water).

Meanwhile there is simple and accessible to any villager and cottager the way out of this situation, which I am pleased to share with readers.

Almost all washing machines (hereinafter – CM), regardless of manufacturing companies and brands have the same working principle.

All input is one or more solenoid valves that feed AC lighting network 220 via the electronic system control and switching.

So specific words should not scare people, even a little familiar with electronics, because the alteration of the washing machine in this part of the “cakewalk”.

To improve the passage of water into the tank of the washing machine, you must remove the rubber gasket in alignment with the inlet solenoid valve. After that, the throughput of the valves will improve.

Next is to remove the top cover of the washing machine (here are the most common CM with a lateral load of Laundry), removing this 2 – 3 (depending on the type of CM) screws at the rear from upper cover. After that the top cover is removed, the translational horizontal movement “by itself” (if to look at the door). Not far from the place of supplying the input hose close by are two (as in the present CM) the solenoid valve. Through the connectors, wires connected. When a CM requires to pour water on the valve is supplied AC voltage 200 to 220 V. They are open and let water into the tank and drum. To electromagnetic valves are four wires (two for each). Connecting in parallel with the contacts of the valve terminal block and connecting a few wires, they are taken out of the case CM.

Now these wires (let’s call them conditionally A and b) connect a homemade power supply of direct current and its output sets low-voltage electromagnetic relay K1. The relay contacts included in the circuit of supply pump. Now, as you may have guessed, when you turn on the input valves of the washing machine will turn on relay K1, and injection pump. When the valves in the washing machine will switch off pump automatically shuts down. This combo will work in cycles indefinitely. And stand by the washing machine is not necessary.

To connect the pump directly to terminals of solenoid valves washing machines can not – due to the large current consumption of the pump “burn” electrician CM.

Fig. 1. The electric circuit improvements of the washing machine

Details

In the diagram (Fig. 1) shows a step-down transformer T1 with an output alternating voltage at the secondary winding 16, rectifier diode VD1 – VD4. Oxide capacitor C1 (of the type K50-24 or similar) inserted in the scheme for smoothing of pulsations on nutrition. Relay K1 – automotive, type 3747-06 designed for a trigger voltage of 12 V. However, it is possible to use both relays, for example, WJ118-1C OMRON’s G2R-112R-V, ТRU-5VDC-blower SB-SL ТТ1-TRD-9VDС-FB-CL, Relpo RМ85-2011-35-1012, RA BV2091 SRUH-SH-112DM, FRS10C-OZ or similar. It is important that the relay contacts provided safe switching of load current less than 3 A.

The diagram shows a piezoelectric capsule with built-in sound generator HA1, a parallel connected relay and the led НL1, connected in series with a current limiting resistor R1. These elements respectively provide audible and visual indicator of the pump (and intake valves of the washing machine). If such an indication (or part of it) is not needed, the corresponding elements are simply removed from the scheme.

The HA1 primer can be any designed for a voltage of 9 to 15 In, for example, FМQ2715D, FХР1205 (single-tone sound), КРІ4332-12 (intermittent sound), КРЅ4518 (dual tone siren) or similar.

The rectifier shown in the diagram (Fig. 1) can be any if only it provided DC output current more than 70 mA when the DC output voltage 12 – 15 V. Suitable industrial rectifier or power supply, for example, from the radio or cautery device. Adapters for cell phones here to use useless, since the output current is insufficient to power the relay.

Here in this simple way, you can automate almost any washing machine in the village and live in the city. Don’t need to find the master installer, who will charge you for such a simple job a lot of money.

Seeming disadvantages

You will need to open the top cover of the washing machine and connected in parallel electromagnetic valves, installing terminal block. If your washing machine is under warranty, opening the lid, you could lose it. Here everyone chooses itself: or “suffer” with the machine, until the end of the warranty, or purchase for this purpose has the old washing machine and to convert any of them in accordance with the above recommendations, and to live comfortably.

Recommend to read TURN TO TURN To make required urgently a small spring — not a problem, if there is at hand a suitable steel wire. You can just use a vise and a rod of any desired diameter. The last will only need to... SIMPLE AND EASY Quick-drying underwear in the kitchen over the gas stove, but there comes a time dining, and hanging over your head, it begins to deliver visible discomfort. And fresh cloth easily...  Modern washing machines are in the process of Laundry is almost without the intervention of the hostess. She can only put the clothes in and pull it out after washing. Therefore, to acquire such dreams of every housewife in the city and in the countryside. But connecting them in the countryside could become a “headache”, as Central water (or sufficient pressure in it), as a rule, there.

Modern washing machines are in the process of Laundry is almost without the intervention of the hostess. She can only put the clothes in and pull it out after washing. Therefore, to acquire such dreams of every housewife in the city and in the countryside. But connecting them in the countryside could become a “headache”, as Central water (or sufficient pressure in it), as a rule, there.