In garden and dacha benches, the seats suffer most from atmospheric exposure: snow caps accumulate on their horizontal surface, which become soggy during thaws, and rain also has its destructive effect. Painting with oil paints certainly helps, but doesn’t save them.

However, there is a way to make the seat as durable as the backrest. How to achieve this is suggested to readers by the Hungarian magazine “Észermester.”

The design of a wall-mounted bench can vary in details, but will remain unchanged in the main thing: its seat must be able to fold, ending up in the same plane as the backrest. Let’s consider two such options.

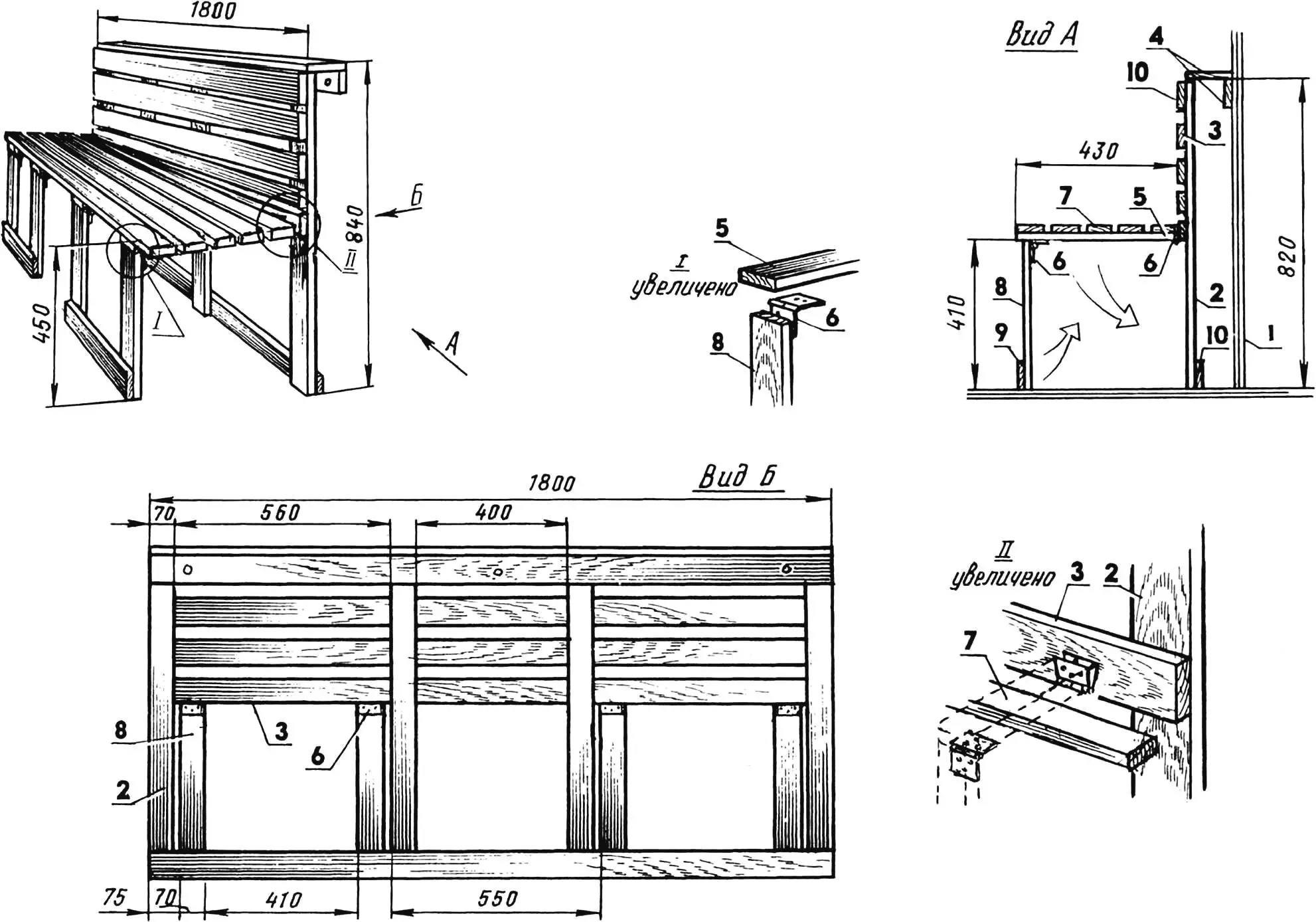

WOODEN SOFA

Its foundation will be the backrest frame, assembled from boards with a cross-section of 70×20 mm. For it, four boards 820 mm long will be needed—for vertical posts and two horizontal ties 1800 mm long. For a small offset of the sofa from the wall and its fixation to it, an L-shaped horizontal bracket is assembled from two boards 1800 mm long. The four backrest boards will be the same length. On the lower one, with an offset from the posts, card hinges are installed, to which four transverse seat boards 430 mm long are attached. Longitudinal boards 1800 mm long are nailed to the latter, forming the actual seat.

1 — wall; 2 — backrest frame; 3 — backrest boards; 4 — bracket boards; 5 — seat crosspiece; 6 — hinges; 7 — decking boards; 8 — support; 9 — support tie; 10 — frame ties.

It remains to assemble its support part. For this, legs made of boards 410 mm long are also attached with hinges to each of the transverse seat boards. To provide greater stability, they are connected at the bottom in pairs with crossbars 550 mm long—resulting in a sturdy support in the form of a half-frame. Thanks to the mentioned hinge joints, before bad weather or for the winter period, such a bench can be folded into a vertical panel: the support half-frames are raised to the seat and together with it are lowered, ending up under the backrest.

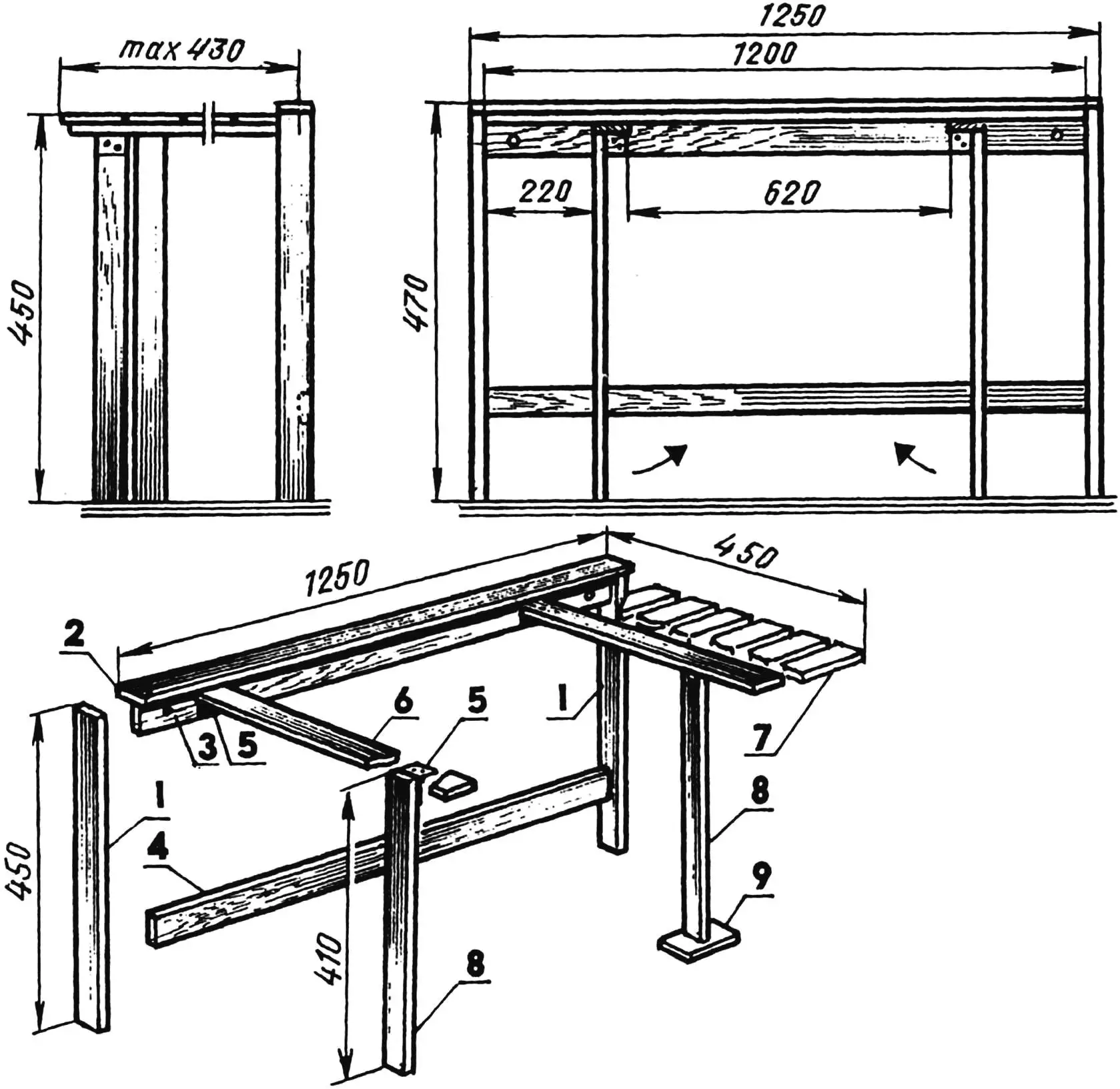

FOLDING BENCH

Another version of a folding bench (fig. 2) is also wall-mounted, but is made without a backrest and with a different scheme for folding the support legs.

1 — frame posts; 2 — frame board, horizontal; 3 — frame tie, upper; 4 — frame tie, lower; 5 — hinges; 6 — seat crosspiece; 7 — decking board; 8 — legs; 9 — foot pad.

A low U-shaped frame consists of three boards with a cross-section of 70×20 mm: horizontal—1250 mm long, vertical—450 mm. The latter are connected to each other by a crossbar made of a board 1250 mm long. Under the upper horizontal board, another one is installed, 1200 mm long, whose plane faces the wall—for convenient mounting. On the other side, two card hinges are installed on it with an offset from the ends of 220 mm, to which transverse seat boards 410 mm long are attached. To them, as in the first version, longitudinal seat boards are nailed. And to the front ends of the crosspieces from below, hinges are also placed, but, unlike the first version, not for longitudinal (relative to the crosspiece), but for transverse folding. Here the legs will be retracted toward each other. So that they don’t overlap each other in this case, the hinges for them on the crosspieces are offset by the width of the leg. The height of the legs is 410 mm. If the surface beneath them is not hard but earthen, it’s better to make wooden foot pads, shortening the legs.

In the folded state, such a bench looks like a panel protected on all sides in a box.

“Modelist-Konstruktor” No. 3’99