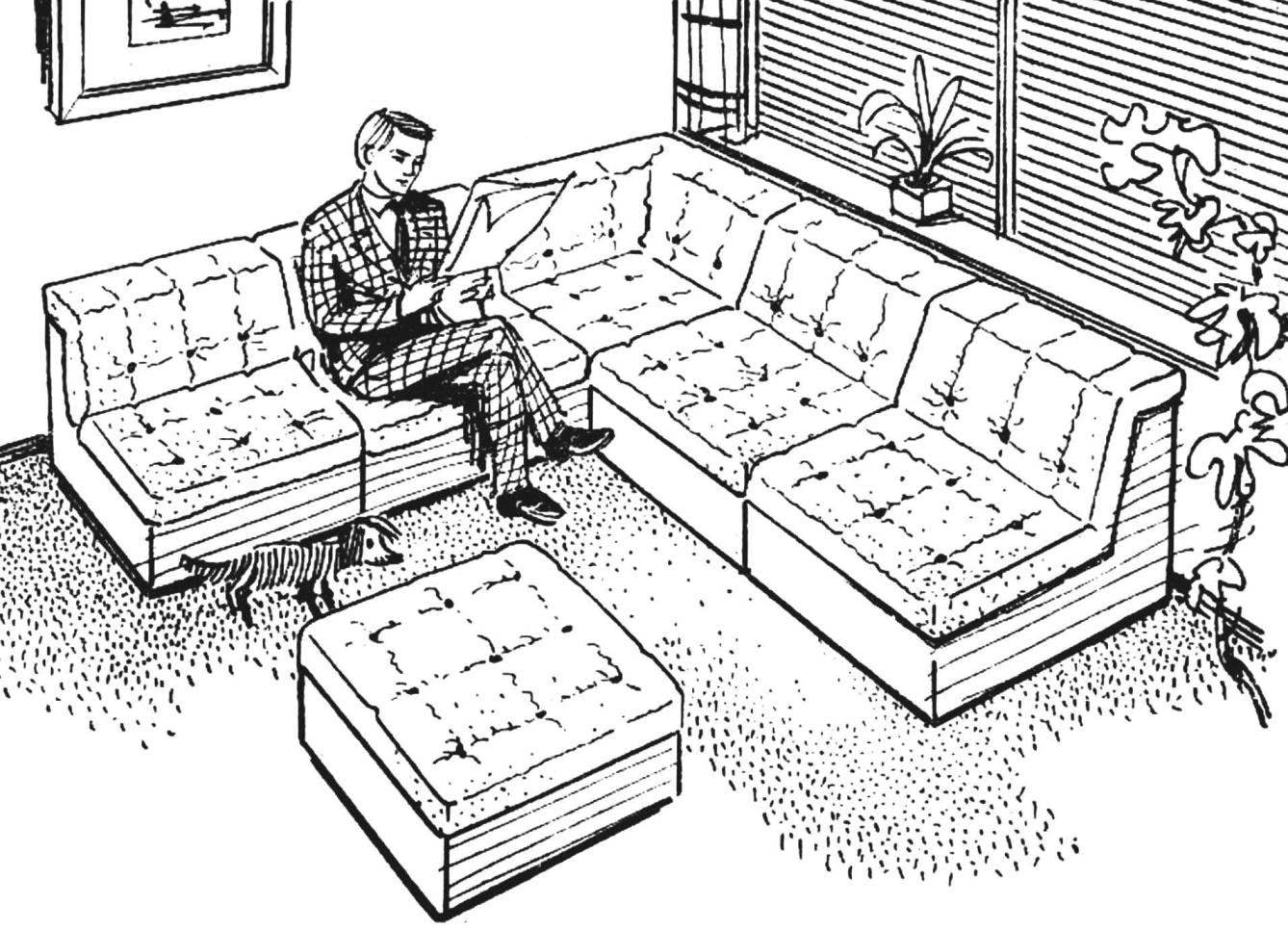

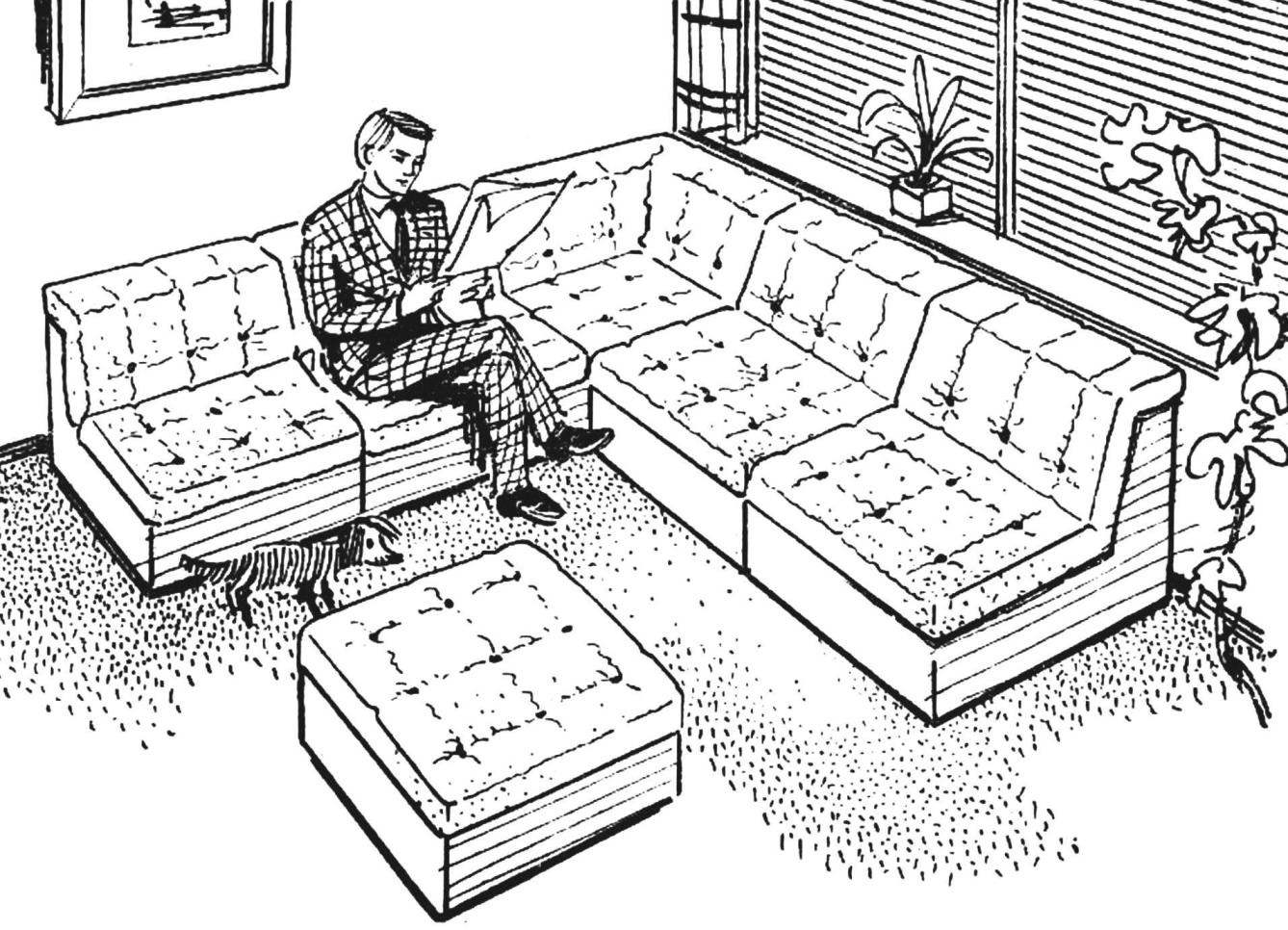

Chair thanks to its “mobility” and flexibility, beyond doubt, an important and interesting part of interior living room. Several chairs can make a variety of ensembles. They can be placed one by one around the low table to move in a row along the wall, forming a kind of sofa, you can fill them and the corner of the room.

Recommended for self-production set of five chairs allows you to make the above-mentioned transformation. And work on it, we are sure you will be on the shoulder: it does not require any cabinetry skills or complex special tool — it is only necessary to carefully implement our recommendations.

The frame of each chair is assembled from wooden bruskov by section 50X50 mm associated cylindrical wooden pins. To the bars of the base are fastened two small front swivel wheel.

For the seat base and backrest, you will need textile or rubber belts or strips of a width not less than 50 mm. Note that for each seat must be at least ten meters of belts. In the places of their attachment bars of the frame are rounded — this will eliminate the chafing. To start the cording strips should be from the front surface of the front of the seat. Each strip is tucked in and secured with three furniture nails with broad heads. To tension all of the belts was the same, pull them before the final fixing is strictly the same size. Note, however, that the tension straps on the backrest should be slightly smaller than the seat base.

The next stage of work — padding the front seats, and side and top bars of the backrest foam. Pre-first should be sealed with a sheet of plywood or thick hardboard. Upholstery will need a strip of foam rubber in the thickness of 20-25 mm. “Sew” them to the furniture with nails. Tight start from the inner part of the upper front of the bar, then follow with foam rubber, lower the bar gently wipe the space around the wheels and fasten the material with the inner side of the bottom and side bars so that the entire front surface of the chair was closed.

The first stage of the manufacture of armchairs — frame Assembly. Connection of individual elements — with wood studs.

Now take the strip of foam the same thickness, 50 mm in width, apply it to the surface of the side bar and sew the nails along the Central line.

The top bar of the front seat back cover with a strip of foam with a width of 100 mm. After the padding, fix the foam vinyl electrical tape, wrapping each bar crosswise.

Now you can start the wrapping frame upholstery cloth. The process is divided into two stages. First cut a strip of material with a width of 355 mm and of such length that its enough for the front of the seat and both side panels. Furniture nails secure the edge strip to the lower surface of the lower bar.

Then wrap the material around the top of the bar and sew it to the textile straps. Next, the fabric is temporarily attached to the side surfaces of the seat, and then nailed to the lower surfaces of the bars of the base. Excess material carefully cut away.

The second phase covering — drape backdrop. This would require a cut of fabric with a width of 610 mm and of such length that it lasted until the middle of the side parts of the frame. Clamp the material first from below, then it must be pulled and “sew” furniture nails to the top bar of the back of the seat and to the side bars. From the side elements of the seat frame to the upholstery sew strips of any flexible material, pull them out and attach to the bottom bar so that they were fixing the draping of the sidewalls — it will help them to “work” by changing the position of sitting.

Next, wrap the fabric around the side bars of the back and gently “nail” material to the inner surface. The corners of the material on the front upper surface of seat stitch coarse thread, and then in the textile straps fasten a piece of foam with dimensions 50X250x610 mm and close the strip of fabric with a width of 380 mm. When suturing the edges of the strip do not pull it too hard — this can lead to tearing of the tissue in the process of operation of the chair.

Seat cushion is a foam parallelepiped with dimensions 100Х545Х800 mm wrapped upholstery cloth. Case sewn in a pillowcase, which is held in a fixed position wide lingerie elastic. (Similarly arranged and cushion for backrest; its dimensions — 75Х445Х800 mm.) of the First cushion connected with the seat by six buttons, the distance between which is about 230 mm. the color of the buttons is selected in accordance with the color and texture of drapery material. To put them in place better than just using a large needle, severe bone and wood studs, which are located inside the chair. Note that the center of each button must match the middle of the cotton belt the chair base.

Suspenda pillow secured with six buttons. Remains sew the seat cushion with the fabric on the side surfaces of the frame, and the top sasenai cushion with the material of the back of the chairs — and the work is finished.

To make the corner chair is no more difficult than that which we have already told. Location textile straps clearly shown in the drawings.

To complete the creation of the headset, you can puff, which will give the kit completeness. His frame from wooden bruskov by section 50X50 mm; it has the same height as the front of the seat of the chair. The top of the frame is delayed crisscross textile straps. Upholstered in the same upholstery fabric as all of the chairs. Square foam cushion placed on the frame in a “pillowcase”, sewn to the drapery material. The bottom of the pouffe has castors on all four corners.

Recommend to read NATIONAL AIRLINER The Il-18. When you create a turboprop airliner Il-18 took its predecessor with the same designation, but piston engines. Special attention in the design of the aircraft, the designers... COIL EXTENSION CORD Iron or drill you need in one corner of the room, and the socket is in another. In this case you can use an extension cord. And for storage you can make a simple and practical device — a...  Chair thanks to its “mobility” and flexibility, beyond doubt, an important and interesting part of interior living room. Several chairs can make a variety of ensembles. They can be placed one by one around the low table to move in a row along the wall, forming a kind of sofa, you can fill them and the corner of the room.

Chair thanks to its “mobility” and flexibility, beyond doubt, an important and interesting part of interior living room. Several chairs can make a variety of ensembles. They can be placed one by one around the low table to move in a row along the wall, forming a kind of sofa, you can fill them and the corner of the room.