due to numerous requests of our readers interested in the publications under this title (see No. 8, 1977, No. 5, 1978), put some more descriptions of decorative designs, metal and wood from the books by famous Yugoslav artist Dmitry Petrovich yourself.

due to numerous requests of our readers interested in the publications under this title (see No. 8, 1977, No. 5, 1978), put some more descriptions of decorative designs, metal and wood from the books by famous Yugoslav artist Dmitry Petrovich yourself.

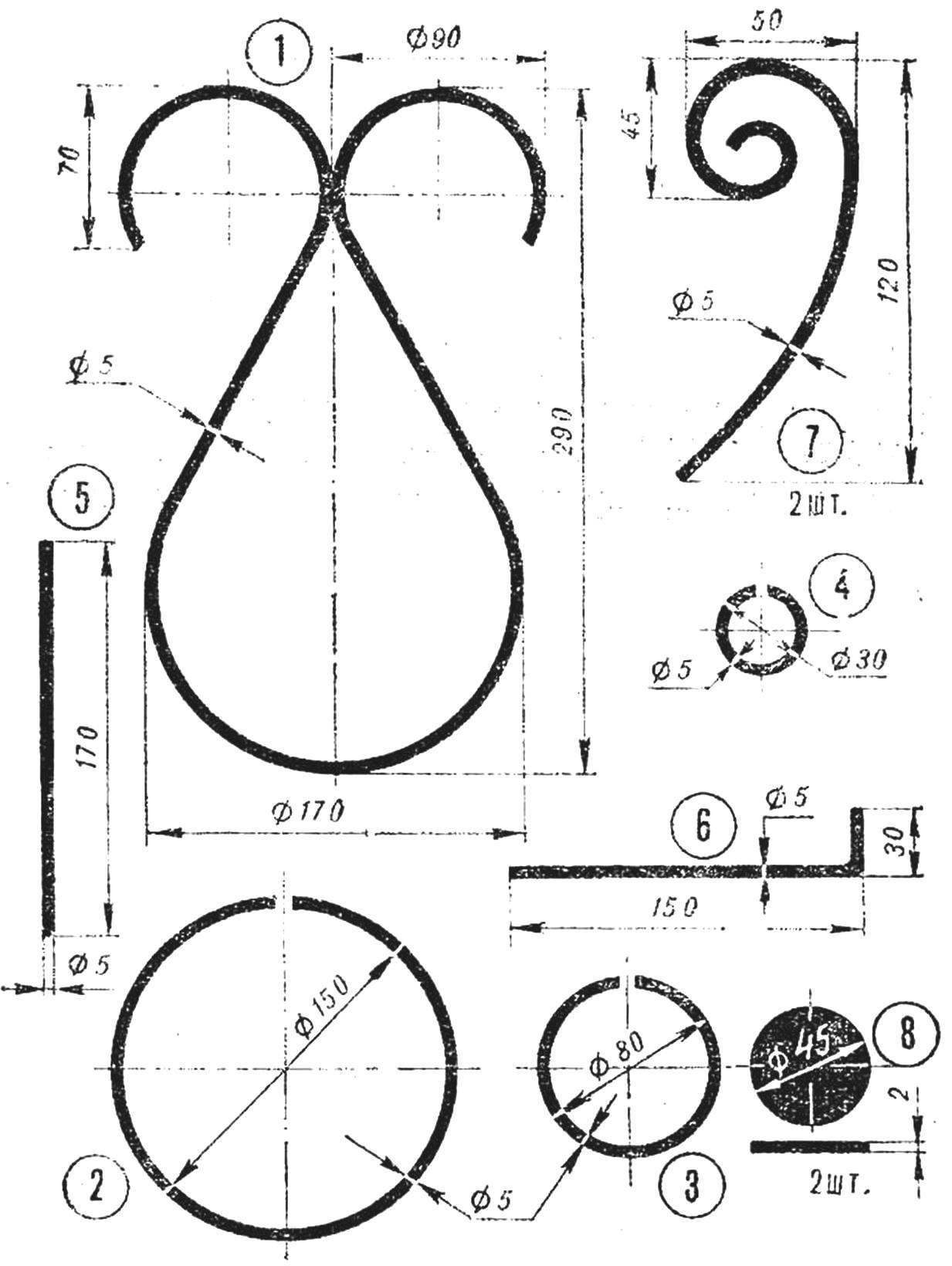

STAND of COLORS

MATERIAL

MATERIAL Rod O 5 mm, sheet metal thickness of 2 mm, primer metal, red.

TOOLS

Hammer, file, hacksaw, welding machine, caliper, meter, brush.

BLANK DETAILS

With a hacksaw cut off from the rod parts of the bracket (1, 5, 6, 7) and rings (2, 3, 4). Is given the form with the help of improvised devices for flexible. Detail of bracket (6) is clamped in the vise and with a hammer is bent at a 90°angle.

Decorative mugs (8) sheet metal hand shears cut, edge processed with a file.

BUILD

To lisoobrobna parts (1) bracket welded decorative mugs (8) and the rod (5) with ring (4). We then also attached in a convenient sequence coiled part (7), rod area (6) and ring (2 and 3).

The finished stand is covered with primer for metal and painted green or any bright color.

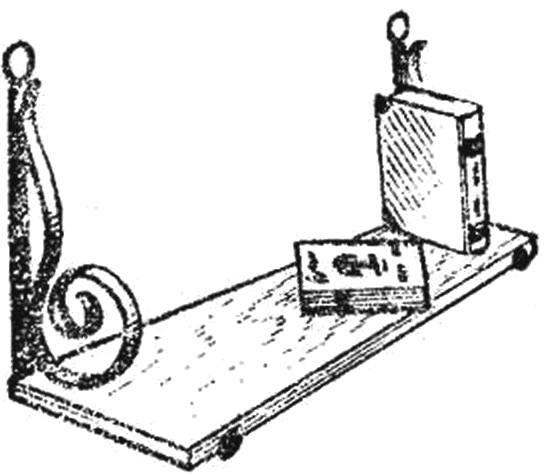

SHELF FOR BOOKS

MATERIAL

MATERIAL Rod O Round 4 mm, square rod 10×10 mm, metal strip 15X3 mm, 10 mm thick plywood, wood glue, clear varnish, primer for metal, paint.

TOOLS

Hand saw, hacksaw, file, hammer, planer, welding machine, angle meter, brush.

BLANK DETAILS

Spiral part (1) side shelves are cut from metal strip and bent.

the vertical part of the bracket (2), horizontal (3) and longitudinal (4) saw off the square bars in the dimensions indicated in the drawing.

Ring for hanging (5) bent from a round bar in a vise. Decorative mugs and constraint (6) can be cut from the strip with scissors or a hacksaw. All the metal blanks are processed with a file and emery paper.

Itself shelf shall be cut from a sheet of plywood 10 mm thick. Edges are processed with a plane and sandpaper. After that, it paste over with decorative veneer or painted.

BUILD

The details of the bracket (2 and 3) are connected at right angles and welded, then they are joined by the longitudinal part (4). To the vertical parts of the bracket (2) welded rings (5) and spiral side (1), the horizontal decorative circles (6).

The whole metal part of the bookshelves is covered with black matte paint. After drying on the wooden shelf bracket is set.

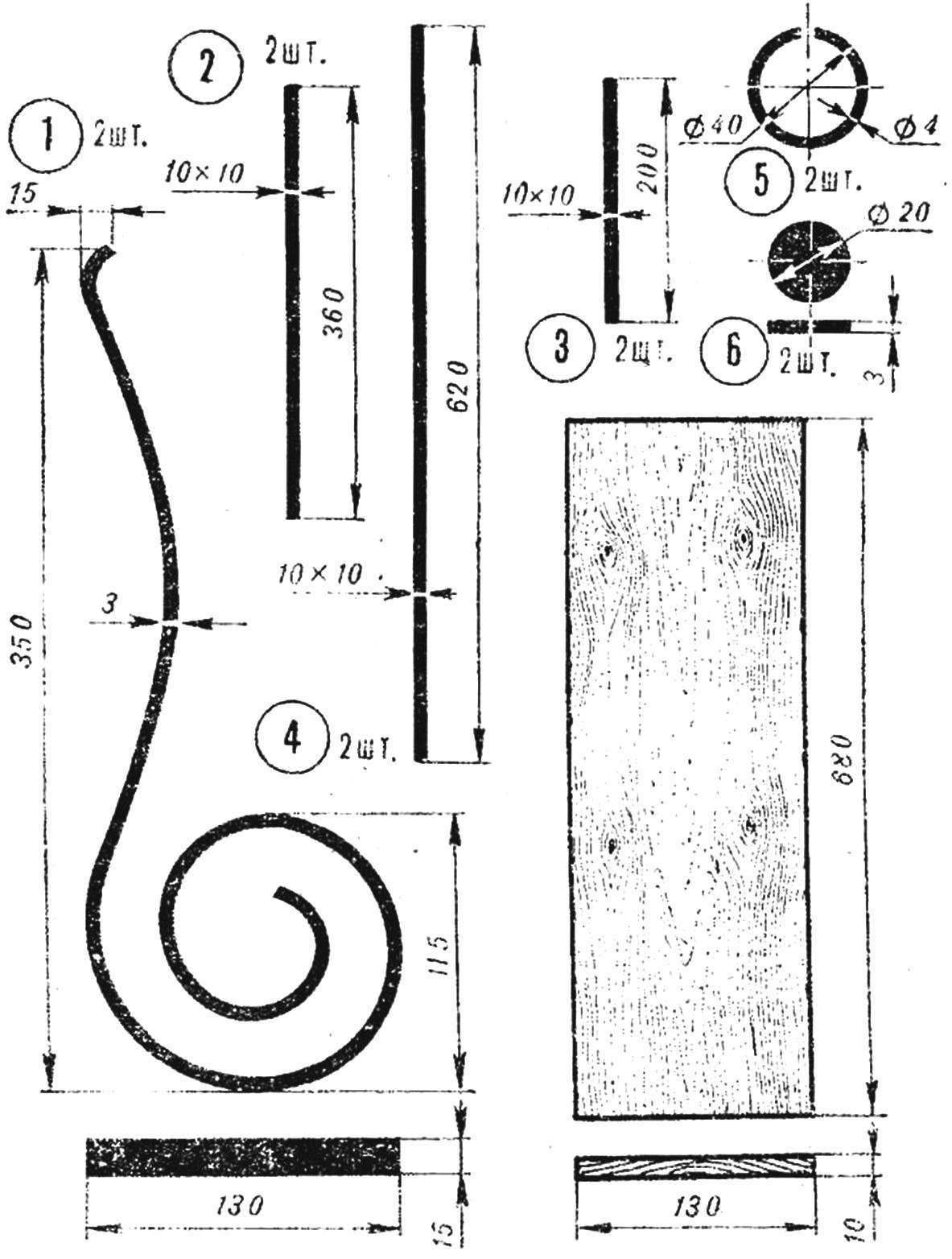

PHONE SHELF

MATERIAL

MATERIAL 10 mm thick Plywood, wood glue, metal strip thickness 2 mm O steel rod 6 mm, veneer, metal primer, paint.

TOOLS

Hand saw, hacksaw, electric drill, file, drill O 4 mm, hammer, welder, vise, sandpaper, plane, square, meter, brush.

BLANK DETAILS

A hacksaw cut off the workpiece elements bracket (2, 3, 5, 7, 8, 10, 11) openwork shelves (1), the ends smoothed with a file.

Then, in accordance with the detail drawing attached to the necessary form.

Detail of the side rails (4) is cut from a metal strip with a hacksaw or scissors, and then angles are treated with a file to obtain a circularity.

Lugs for suspension of the shelf is also cut off from the strip, they must be drilled drill hole O 4 mm, edge processed with a file or sandpaper.

Top shelf (6) is cut out of plywood manually piloi, all the rough edges smoothed with sandpaper. The bottom and side surfaces of the shelf can be painted dark colors, top — to paste over with decorative veneer.

BUILD

Figure parts (1) hollow shelves are stacked on a flat surface and are welded to each other. Right angle are welded to each other the details of the bracket (10 and 11), and thereto — connected parts openwork shelves and a support element (3) wooden Shelves. Then the corresponding sequence welded to other parts (5, 8, 9, 2 and 4).

The welding is processed with a file and sandpaper. The surface of The assembled structure is primed and after drying is covered with several layers of paint.

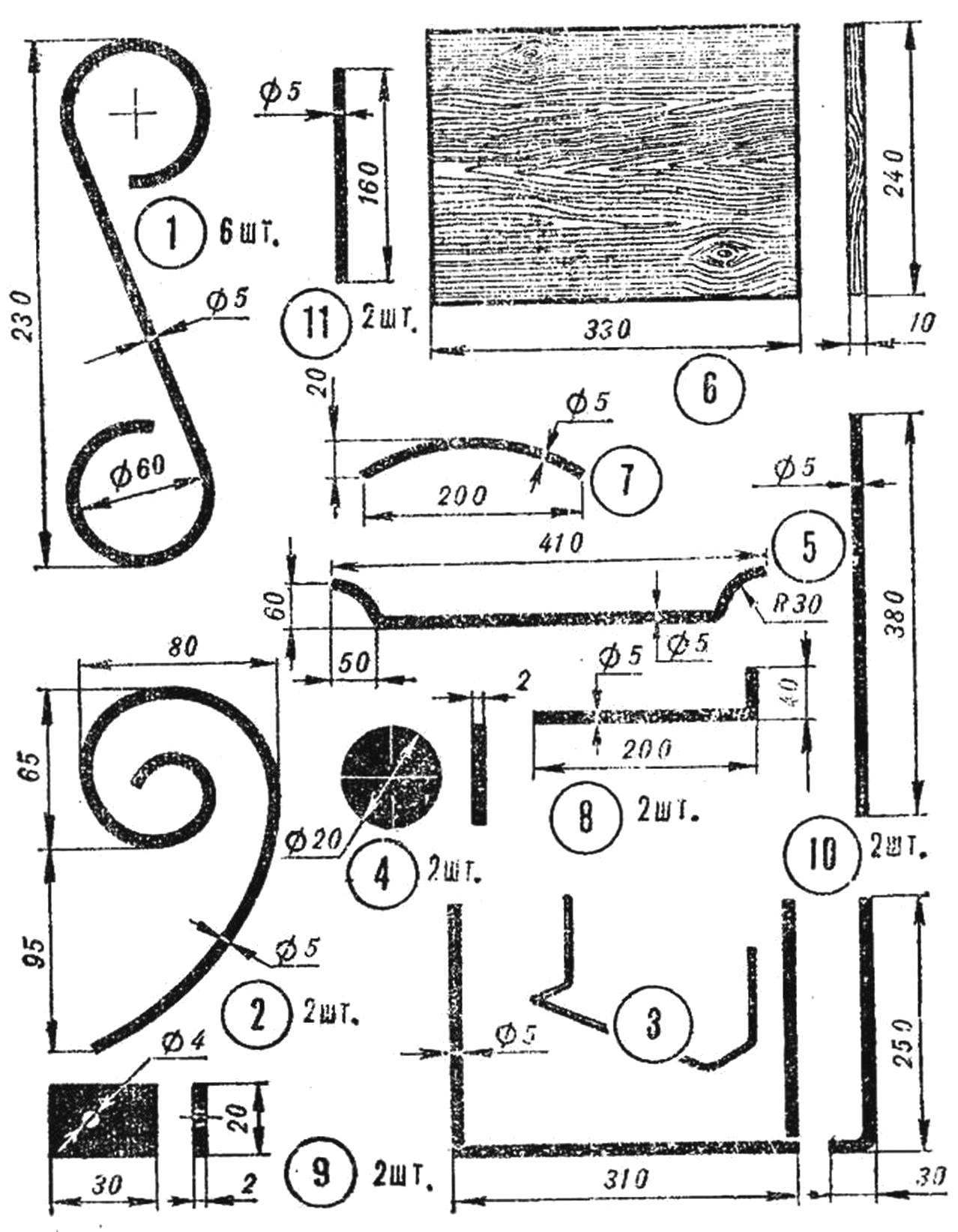

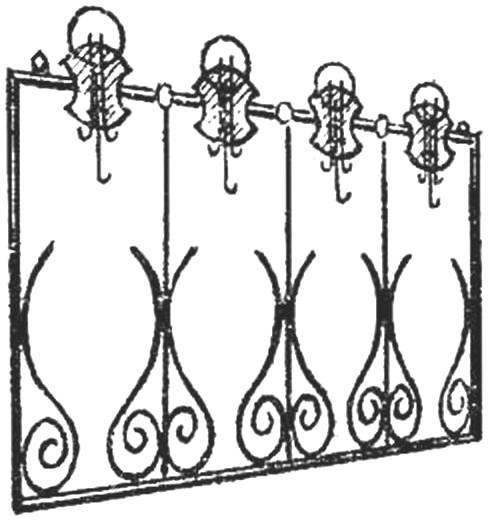

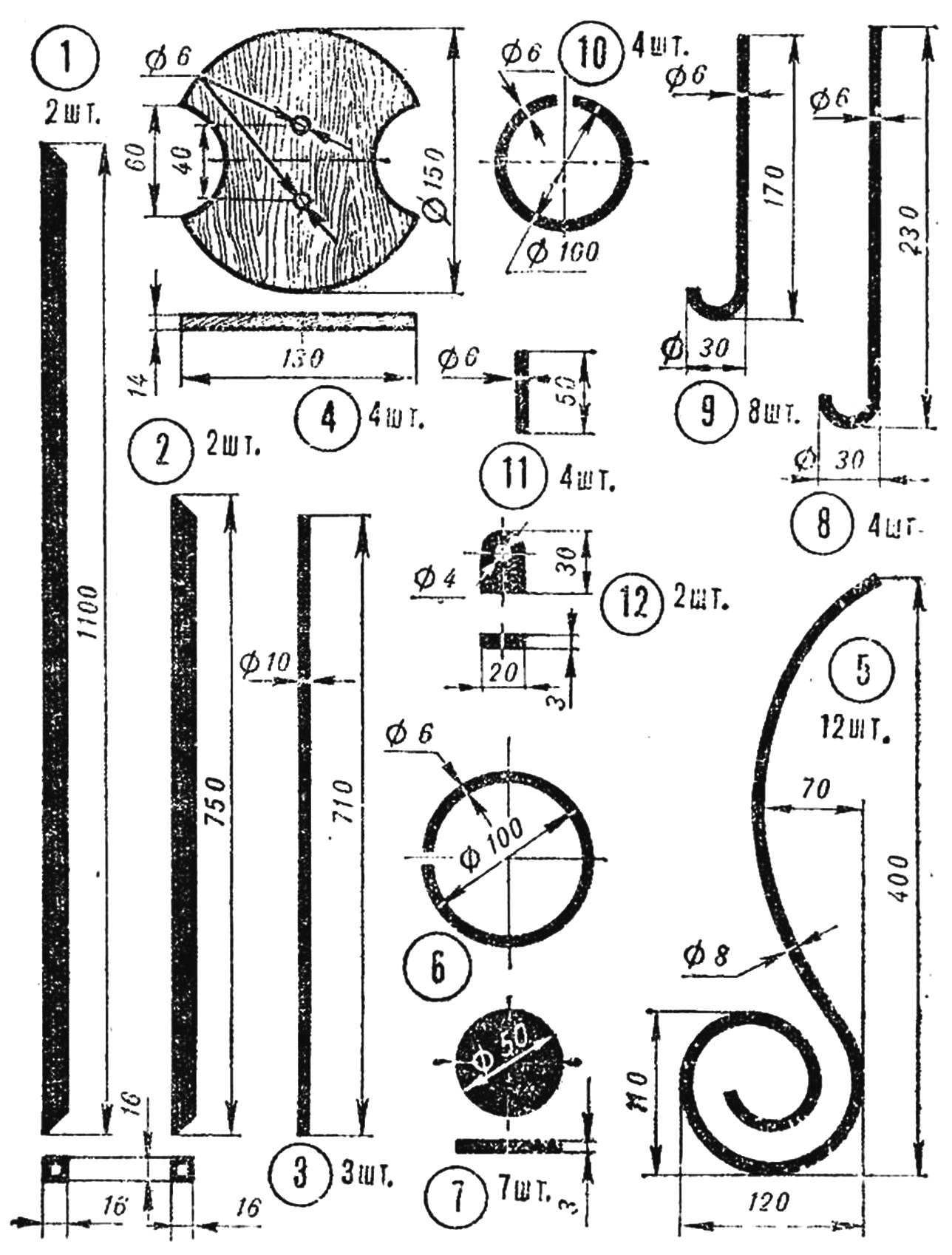

CLOTHES HANGER

MATERIAL

MATERIAL Metal rod O 6, 8 and 10 mm, square tube 16×16 mm, sheet metal thickness 2 and 3 mm plywood 14 mm thick, bolts М6Х50, primer for metal, paint.

TOOLS

Drill, drill O 4 and 6 mm, hacksaw, file, hand saw with a narrow blade, wood rasp, half-round, welding machine, meter, brush.

BLANK DETAILS

Frame parts (1 and 2) are sawn off at a 45° angle to the square tube. It is necessary to check the correctness of the determined angle; if it does not match the 45° — to modify it with a file.

Three transverse bars of frame (3) and three short to connect the hooks of the hangers are sawn off from a circular rod. Hooks hangers (8 and 9) cut from a round bar and bend in a vise. The details of the hangers (4) from thick plywood are cut with a hand saw.

The helical part (5) bend with the help of any auxiliary devices. Decorative ring (10) bend on the horn of the anvil or pipe of suitable diameter.

The circular plate (7) are cut with a hacksaw or cut big scissors for metal.

BUILD

Frame parts (1 and 2) are welded at an angle of 90°, the connection of the processed file. Transverse bars (3) are welded to the frame at the same distance; from the top at the junction of the circular plate (7). To the bottom of the frame are welded the spiral decorations. In the upper part of the bolt that is welded to the frame, and fasten wooden parts (4). Hooks hangers (8 and 9) are welded to transverse stretches, and decorative rings (10).