The first thing that comes to mind after Novoselov obtain a warrant for the apartment – such as drilling holes in concrete walls, how to attach the hooks to the asbestos cladding? Meanwhile, a variety of designs, there are many traffic jams, and you will always be able to do any of them, taking into account the thickness and strength of the wall, its technical capabilities and the number of required hooks and screws. The simplest option – all known wooden plug of solid wood. Its cross section should slightly exceed the diameter of the prepared hole. Cork hammered with a hammer, then drill its center, thinner than the intended nail or screw, nasverlivaetsya hole. Unfortunately, such plugs do not always provide sufficiently reliable fastening: wood rassyhaetsya from time to time, and seemingly firmly reinforced eaves curtains or favorite printmaking fall on your head.

The first thing that comes to mind after Novoselov obtain a warrant for the apartment – such as drilling holes in concrete walls, how to attach the hooks to the asbestos cladding? Meanwhile, a variety of designs, there are many traffic jams, and you will always be able to do any of them, taking into account the thickness and strength of the wall, its technical capabilities and the number of required hooks and screws. The simplest option – all known wooden plug of solid wood. Its cross section should slightly exceed the diameter of the prepared hole. Cork hammered with a hammer, then drill its center, thinner than the intended nail or screw, nasverlivaetsya hole. Unfortunately, such plugs do not always provide sufficiently reliable fastening: wood rassyhaetsya from time to time, and seemingly firmly reinforced eaves curtains or favorite printmaking fall on your head.

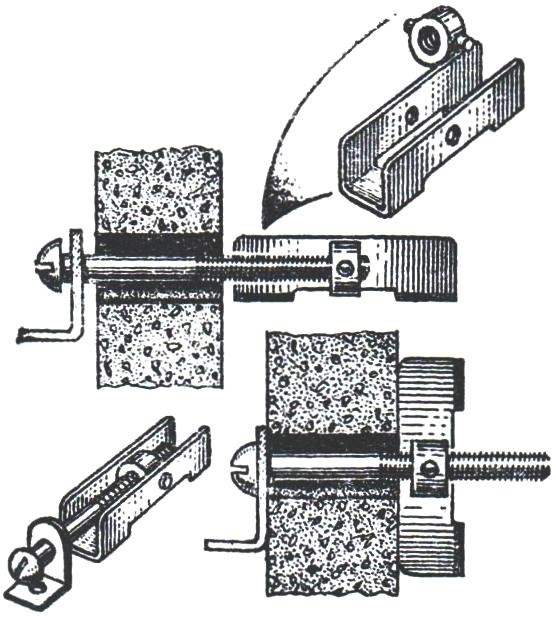

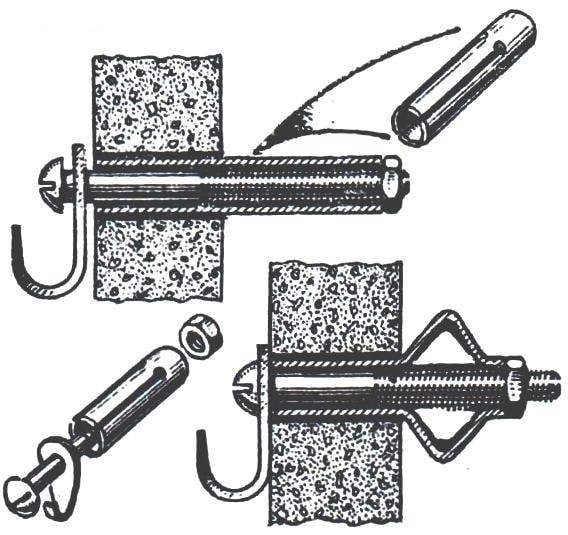

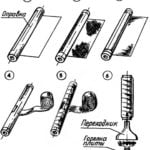

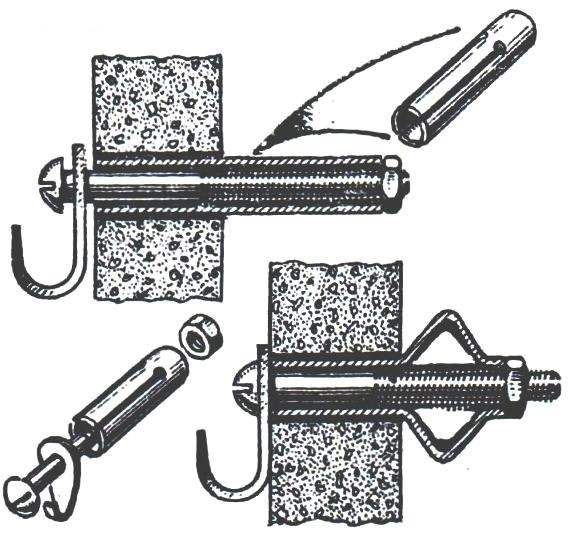

For hollow as asbestos, you can choose one of the options below. For example, a long screw with a continuous thread (Fig. 1). But the trick is not in the screw and the bracket in a special form, the interval of the U-shaped profile with a hole drilled in the middle of the diameter of the screw. The nut is not quite normal – it is cut from the steel sheet so that it remained on the two “ears”. They are introduced into holes in the bracket – and the adaptation is ready. Screw the nut on the baits, hook set and passed along the screw into the hole. After that, just start wrapping the screw as the bracket unfolded by 90 °, and has no power will not be able to remove it from the wall. Prior to the assembly under the screw head podkpadyvaetsya hook, ring and so on. N.

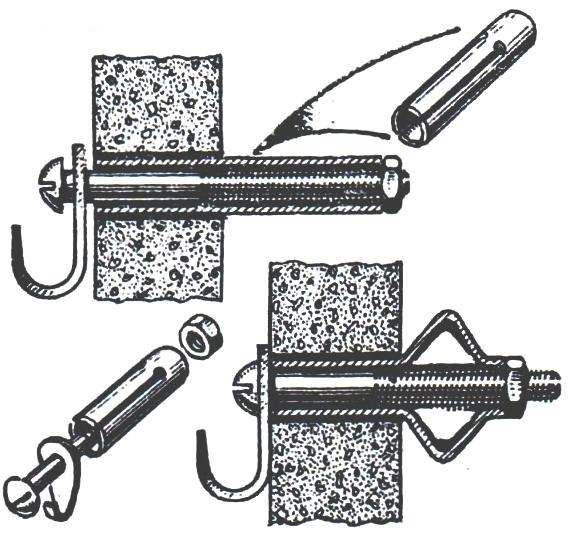

Here’s another tube design -from aluminum tube with an inner diameter slightly larger than the screw diameter. Use the hacksaw on the handset is a longitudinal cross-shaped incision – a stopper ready to use. In the wall of the hole is done, the device is put into it, and reaches up to the stop nut (Fig. 2).

This fixture is suitable not only for through holes, but for the Deaf.

Fig. 1. Fasteners for thin wall

Fig. 2. What kind of plug can be made of aluminum tube

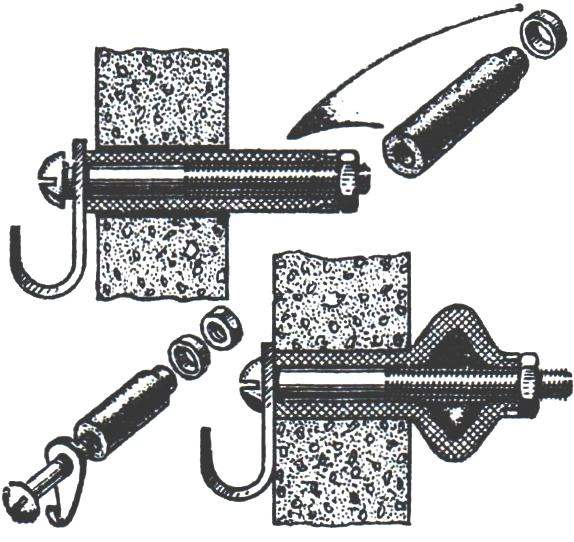

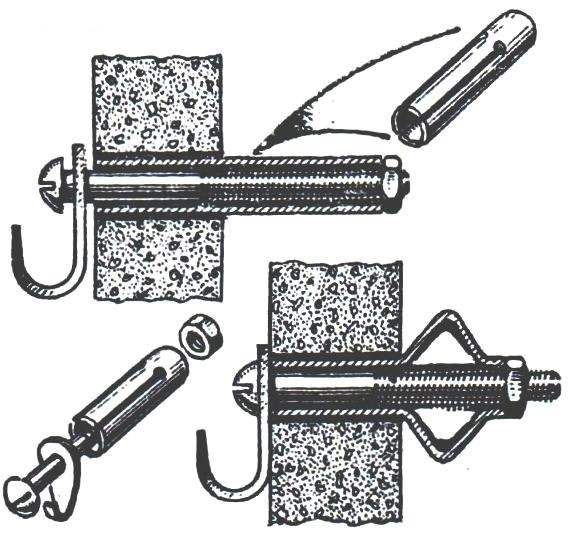

Fig. 3. The rubber tube also can be useful …

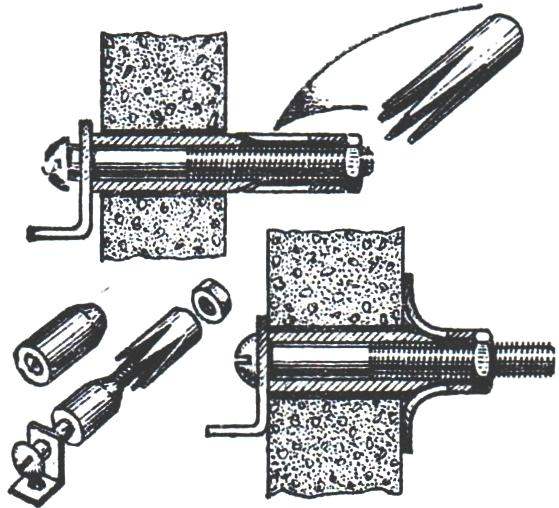

Fig. 4. Another cork – made of aluminum

Small note: pitch bend tube to the desired location on its outer side a shallow groove saws needle files (0.25 mm).

In cases where the wall cladding prevents the use of a rigid plug design helps you thick-walled rubber tube (Fig. 3). Fixing is similar to the previous one, with the only difference that no slots do not have to. At the end of the tube, it is desirable to pull the retaining ring.

From metal tubes can be made of a few relatively simple and reliable traffic jams. Here is one of them. At the end of the tube is performed several cuts formed “tails” slightly bent. On screw successively skewer hook, spacer, cut the tube and nut. The resulting package is inserted into a pre-drilled hole in the wall. It remains to tighten the screw, and the “tails” will disperse to the sides, providing a completely reliable fastening (Fig. 4).

Everything is good, you say, but how to make the hole? Reinforced concrete is very inconvenient material for the drill, but if you want and it can be fast enough to drill any hole.

Here is one method. First of all you need to unfolding of suitable diameter; its end is sharpened like a chisel. Use it in the same way as the jumper: set at the selected location and the light tapping of a hammer on a sweep that after each stroke is rotated by a small angle, knockouts. At the opening of about 6 mm in diameter, will go only 10-15 minutes.

The same zubiltse can be done not only from the scan, for this purpose is quite suitable and conventional drill, it should only sharpen the “rake”.

But the best hole is obtained by using an electric drill and pobeditovye. In this case, however, there are difficulties with its regrinding, which can be done only on the high-speed range of the winepress with corundum.

And a few small tips: do not hammer nails into the concrete walls-even if they are there and will then will not hold still; do not try to hastily turn the screws into the planed casually and somehow pocketed the wall plug, do not take a couple of evenings and make the right amount of congestion on our recommendations.

Recommend to read

NEW TECHNOLOGY

NEW TECHNOLOGY

With all the advantages of fiberglass hulls for model rockets the traditional process of production is highly labor-intensive and unsound. Meanwhile, the conversion gave the modelers a... IN SUMMER — MOTORCYCLE, IN WINTER — SNOWMOBILE

IN SUMMER — MOTORCYCLE, IN WINTER — SNOWMOBILE

Snowmobile technology is finding increasingly wider application today. Industry and amateur craftsmen create the most diverse machine designs, specifically intended for winter operation....

The first thing that comes to mind after Novoselov obtain a warrant for the apartment – such as drilling holes in concrete walls, how to attach the hooks to the asbestos cladding? Meanwhile, a variety of designs, there are many traffic jams, and you will always be able to do any of them, taking into account the thickness and strength of the wall, its technical capabilities and the number of required hooks and screws. The simplest option – all known wooden plug of solid wood. Its cross section should slightly exceed the diameter of the prepared hole. Cork hammered with a hammer, then drill its center, thinner than the intended nail or screw, nasverlivaetsya hole. Unfortunately, such plugs do not always provide sufficiently reliable fastening: wood rassyhaetsya from time to time, and seemingly firmly reinforced eaves curtains or favorite printmaking fall on your head.

The first thing that comes to mind after Novoselov obtain a warrant for the apartment – such as drilling holes in concrete walls, how to attach the hooks to the asbestos cladding? Meanwhile, a variety of designs, there are many traffic jams, and you will always be able to do any of them, taking into account the thickness and strength of the wall, its technical capabilities and the number of required hooks and screws. The simplest option – all known wooden plug of solid wood. Its cross section should slightly exceed the diameter of the prepared hole. Cork hammered with a hammer, then drill its center, thinner than the intended nail or screw, nasverlivaetsya hole. Unfortunately, such plugs do not always provide sufficiently reliable fastening: wood rassyhaetsya from time to time, and seemingly firmly reinforced eaves curtains or favorite printmaking fall on your head.