But even professional builders are reluctant to agree to build such delicate structures as required neat installation of each brick (and sometimes their reinstallation), continuous instrumental monitoring of the nest is all it takes a long time. In addition, maintaining a thin, even seam and ensure strict verticality of the septum (deviation not more than 1 cm to full height) require a high degree Mason. Quite time-consuming and dressing or fastening of these walls with load-bearing structures of buildings: walls, floors, ceilings. Therefore, the cost of the lining is very high.

However, if the payment of a bricklayer no means, it is possible to undertake the construction of walls yourself with the help of fixtures.

In the case where the construction of the partitions entails the redevelopment of the premises or increase the loads on the floor in high-rise buildings, their device requires the consent of the relevant local administrative authorities.

Construction of concrete Foundation under the partition in a quarter of a brick:

1 —ground; 2 — backfilling (sand and gravel); 3 — sand-cement screed; 4 — concrete Foundation; 5 — mortar pillow; 6 — plaster; 7 — anchor plate; 8 — the mortar seam; 9 — brick walls, 10 laga floor; 11 — clean floor; 12 — waterproofing

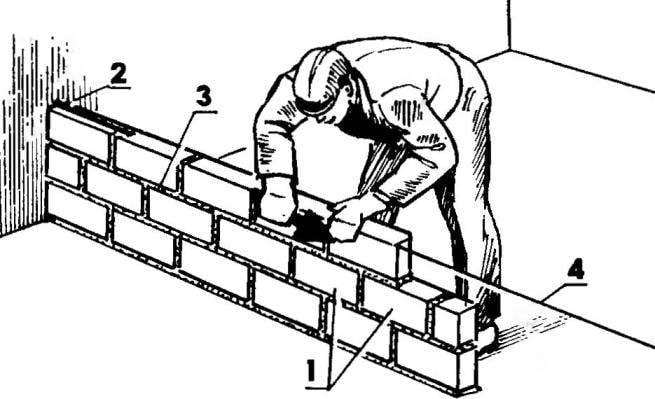

Masonry walls in a quarter of a brick on prichalke:

1 — bricks, laid on a stretcher; 2 — anchor pin; 3 — mortar joint; 4 — mooring cord

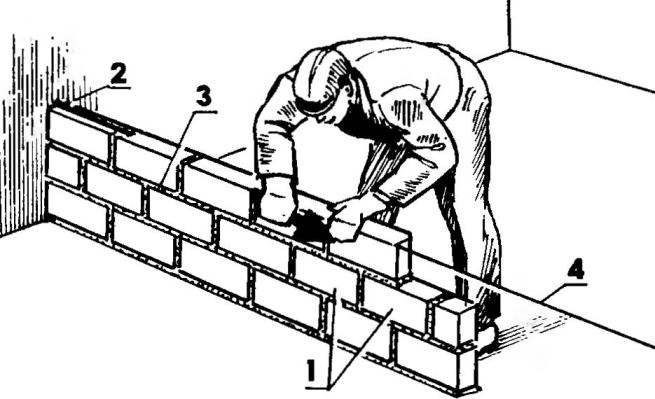

Masonry walls in the quarter of brick with the guide Board:

1 — mesh; 2 — strut; 3 — hole; 4 — peg; 5 — batten; 6 — partition

You must also consider that brick walls can be erected only on the concrete slabs and in one-story buildings without a basement they need to make weakly deepened Foundation on a sand cushion. The pillow must be sunk to a stable pound. The height of walls should not exceed three, and the length of five meters.

Experienced bricklayers lay out the rows on a cord-prichalke, checking the verticality of a wall with the plumb line. The device consists of two racks — hardwood boards section 100x100mm, length slightly less than the height of the room and wide (not less than 150 mm) boards thickness of 40-50 mm of the same length as partition. The boards and the Board should be smooth, both faces of the Board and one face of the boards — smooth (prostranim) to keep the Board from slipping between the wall and the racks and it did not stick solution. Board fixture is placed on edge along the outside line of the partition and close to it, near the ends, should be installed vertically (plumb) and zakleivayut bars racks. In the upper edge of the Board next to the posts driven into the two loops from the nails and become attached to them cuts a strong cord. The cord thrown through the same loops, hammered on the sides in the upper part of the uprights, and attached to nails driven into the rack downstairs. If the partition consists of two perpendicular walls, it is a good idea to make the corner pattern of the pair shot down at a right angle boards and set it on the corner and stand vertically, breaking.

But before you mount the fixture in place, you must perform some preparatory work. No less important than the evenness and verticality of the walls is ensuring its connection with the load-bearing structures, especially walls. Together, these factors largely provide reliable stability of a partition, especially in the case where it is not plastered.

Usually partitions are organized after the erection of the main building envelopes. If main walls of brick, the builders in place of an adjunction of partitions to leave a vertical toothing (protrusions of the bricks through a series-the other half or the same sockets in the masonry). If indent not, nests and even a solid slots to do, especially because modern slotting machines and cutting tools allow you to select them quickly and efficiently even in concrete walls.

The greatest difficulty for such work represent reinforced concrete structures. Make them the nest, and the more the slots, without violating the integrity of fittings, virtually impossible. For fixing the brick partitions to a wall using another method. In main wall, at the junction of her walls, approximately in the middle of the thickness of the latter at the height of the second row (about 25 cm from the floor) drill hole depth at least 100 mm under the steel anchor pin, which is made from reinforcing wire with a diameter of 6-8 mm. One end of the pin vmurovyvayut in this hole, and the other, a length of 400-500 mm in the horizontal seam of the baffle. Pins set throughout the height of the partitions periodically through 3-4 rows on a laying course.

This method is applicable to concrete and brick walls, and in the latter instead of the anchor pins is better to install steel strip section 30s(3…5) mm of the same length as the pins, hammering them into the horizontal mortar joints of masonry of the main wall. If the wall is installed from one wall to the other, then fastened it to the opposite wall.

The brick masonry partitions in a quarter of a brick is chosen with smooth edges, free of cracks, with variation in the linear dimensions of no more than 3 mm. To ensure ligation of vertical joints required and halves, and “three or four” bricks. Solution — cement or cement-limestone of medium hardness. The organization of the workplace is simple: right — capacity with a solution, left — pan with brick. The bricks can be procured on Board, laid on top of the mortar container. Tool: trowel, kirochka, cowardace, and to monitor— plumb, level, rule. At the height of the masonry above the growth necessary scaffolding with goats.

Before the construction of the wall on the slab (or Foundation) it is necessary to lay waterproofing of roofing or asphalt, and on it to distribute a layer of mortar. This layer is not only underlying, but also leveling, and its thickness should be such to provide strong horizontal top plane of the first row of masonry. The vertical seam is filled, causing the solution on the front pre-butting — minor (end) face of the brick, and install it at the same time holding to the rear butting the already laid bricks and a Board fixture. The first and the last bottom row of bricks must be intact.

The angular template and ligation perpendicular to walls partitions

The options of dressing walls in a quarter brick capital brick wall

Mount the partition in a quarter brick with a concrete wall:

1 — load-bearing reinforced concrete wall; 2 — anchor pin (rebar d6); 3 — brick walls; 4 — mortar joint; 5 — the level of finished floor; 6 — mortar pillow; 7 — waterproofing; 8 — brick; 9 — plaster

The sequence of stacking of bricks at the end of the series

The seams partition vpodrezku

The treatment options of seams of the brickwork

a— vpodrezku; b — convex jointing seam — jointing the concave seam; g— a raked joint (when laying in a quarter of a brick is not used)

After careful reconciliation and adjustment provisions of the bricks of the first row raise the Board fixture so that its upper edge towered over the bricks 13 cm (12 cm brick height plus 1 cm — the thickness of the solution). Then with a trowel evenly distribute the solution on the top of the bottom row and are laying the next row, overlapping the previous vertical seams, at least a quarter of a brick. However, all of the extreme surface of the bricks included in the groove or socket before installation, is also coated with the solution. The latter are installed in a row of bricks before laying the coated with mortar both end faces.

If the surface of the wall is not going to plasterers, it is necessary to ensure that the seams (both horizontal and vertical) was completely filled with solution. In this case, in stitches every fourth row the full length of the walls need to lay reinforcing wire mesh or rod with a diameter of 5-6 mm.

So consistently continue the brickwork, raising each time the Board fit on one row and do not forget to clean it from adhering solution.

A clutch of two the last (top) rows of the ceiling are at the same time. Having laid a brick the next to last row as usual, behind him lay the last brick of a number, pre-coat solution not only of its end face, but also the top. Extreme bricks of the last row as the bottom, must be integers. After shvatyvanija a solution every brick of the top row must be jammed to the ceiling with shards of brick or metal pins. Wooden wedges shall not be.

To handle the seams better vpodrezku. Unwanted deep concave jointing tool, and the more convex the seam. The raked joint is unacceptable in this case.

A. POLIBIN

Recommend to read THE MACHINE CALLS In most of our schools calls still include the old — fashioned way of push-button attendant or watchman. But this process is not difficult to automate. Proposed device designed for this... SNAKE IN THE POCKET What a pleasure to start the thread right under the clouds even a simple crossing of two strips, covered with tissue paper! But in our time it is available only to inhabitants of rural...

Partitions of brick in construction are widely distributed. Without them it is difficult to do even in houses built of wood. In many cases, for example, in the construction of sanitary units, boiler rooms and other similar areas, brick walls are simply irreplaceable. They are fireproof and moisture proof, environmentally friendly, not susceptible to rot, frost, do not lose strength at high temperatures and thus do not emit harmful substances.

Partitions of brick in construction are widely distributed. Without them it is difficult to do even in houses built of wood. In many cases, for example, in the construction of sanitary units, boiler rooms and other similar areas, brick walls are simply irreplaceable. They are fireproof and moisture proof, environmentally friendly, not susceptible to rot, frost, do not lose strength at high temperatures and thus do not emit harmful substances.