“Juice with a jack” — that’s what the article was called, published in “Modelist-Konstruktor” No. 4 for 1998. I liked the simplicity and unconventionality of the technical solution proposed in it.

However, I prefer to use a special unit of sufficient productivity for household use instead of a jack. All costs for making such a mechanical assistant pay off quite quickly, and the quality of the resulting juice does not cause any complaints.

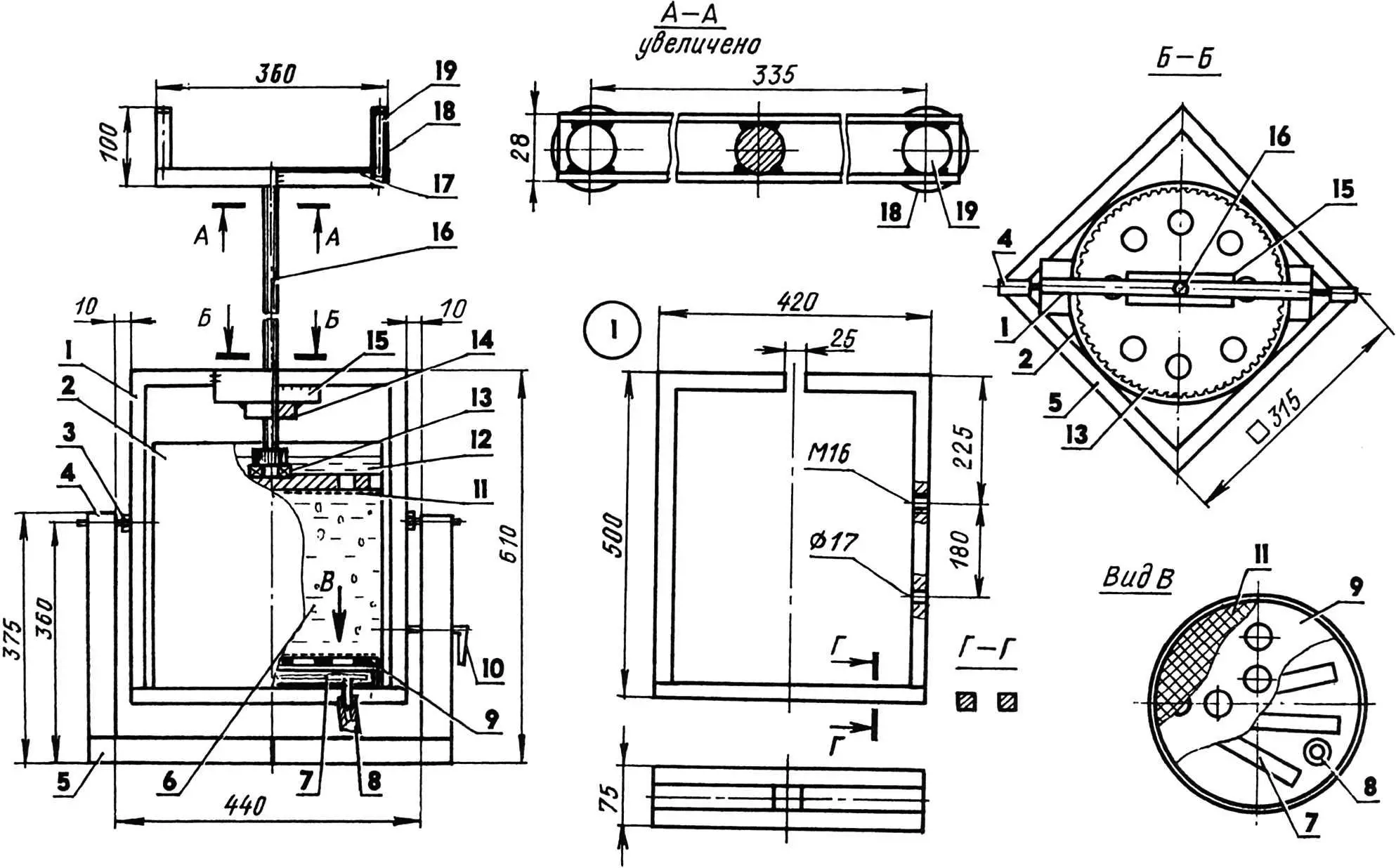

The basis of the homemade juice press is a manual screw press. Raw materials, for example, crushed apples, are placed in a tank on a swivel frame that is fixed during operation. Most of the pressed juice enters a cavity separated from the pulp by a perforated tray with a mesh, while a smaller part is filtered through a pressing disc with the same mesh and flows through a hose into a container (not shown in the figure). The pulp remains clamped between the meshes and is removed only after the juice is drained.

1 — swivel frame (steel rod 25×25); 2 — tank (stainless steel); 3 — left half-axle with M16 nut; 4 — left post (steel tube 40x26x3); 5 — base (steel tube 35x35x3); 6 — raw material (crushed apples); 7 — pad (oak, dimensions as needed, 4 pcs.); 8 — fitting with drain hose; 9 — tray (from a samovar-type water heater, perforated); 10 — swivel frame lock; 11 — mesh (2 pcs.); 12 — juice; 13 — pressing disc with bearing 98205; 14 — lead screw nut (from a lathe); 15 — plate (steel plate 160x50x10, 2 pcs.); 16 — lead screw (from a lathe); 17 — handwheel; 18 — right handle (steel tube 31х3, L70); 19 — right handle axis (steel rod, L100)

The unit design is calculated for modest capabilities of a home workshop and does not require lathe work. Only a welding machine is needed (made, for example, according to a design published in “Modelist-Konstruktor” magazine No. 1’97) and literally materials picked from scrap, including a lead screw with a nut.

The tank with tray is preferably taken ready-made (say, from a decommissioned samovar-type water heater). But it can also be welded from a 3-mm sheet of stainless steel, if such is found. And as a pressing disc — adapt a reel gear from a decommissioned SK-4 combine, slightly grinding off the sharp teeth and edges with sandpaper. The thrust bearing 98205, necessary to reduce the effort when screwing the juice press lead screw, can be taken from an automotive clutch.

The swivel frame is welded from a steel rod with a cross-section of 25×25 mm. The unit base is also welded — from a square-section steel tube. And the posts — from a rectangular-section tube.

Other details are clear from the figure. The only thing missing there is the container tipping limiter — a welded steel plate, the position and dimensions of which are determined during the manufacture of the juice press.

K. PANASYUK