Material: metal rod Ø 3 mm, metal profile 8X8 mm, non-ferrous metal sheet with a thickness of 3 mm and a strip thickness of 2 mm, mirror, black matte paint. Tools and equipment hacksaw, file, hammer, metal shears, needle for marking, blowtorch, welding machine, meter and brush.

Material: metal rod Ø 3 mm, metal profile 8X8 mm, non-ferrous metal sheet with a thickness of 3 mm and a strip thickness of 2 mm, mirror, black matte paint. Tools and equipment hacksaw, file, hammer, metal shears, needle for marking, blowtorch, welding machine, meter and brush.

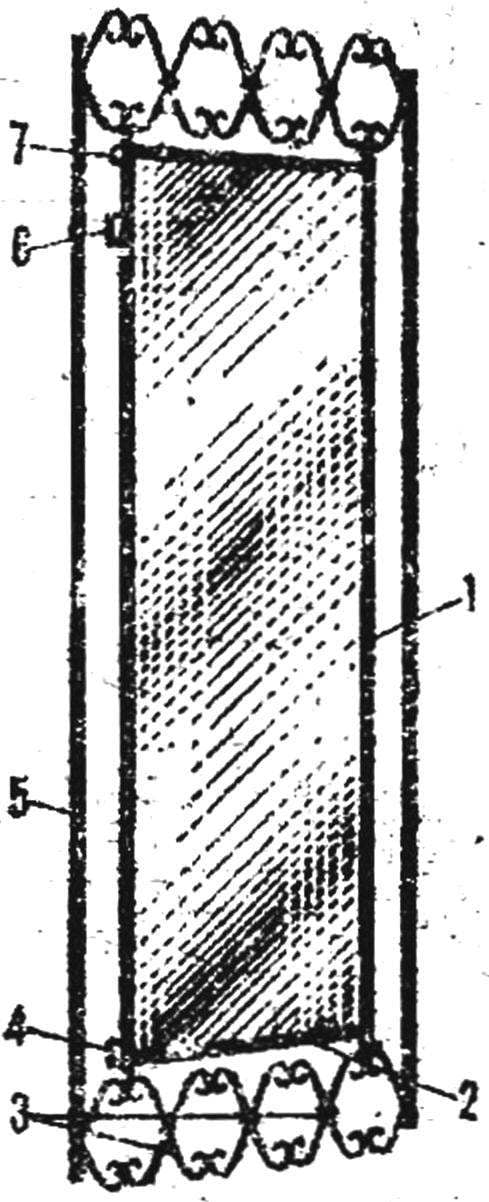

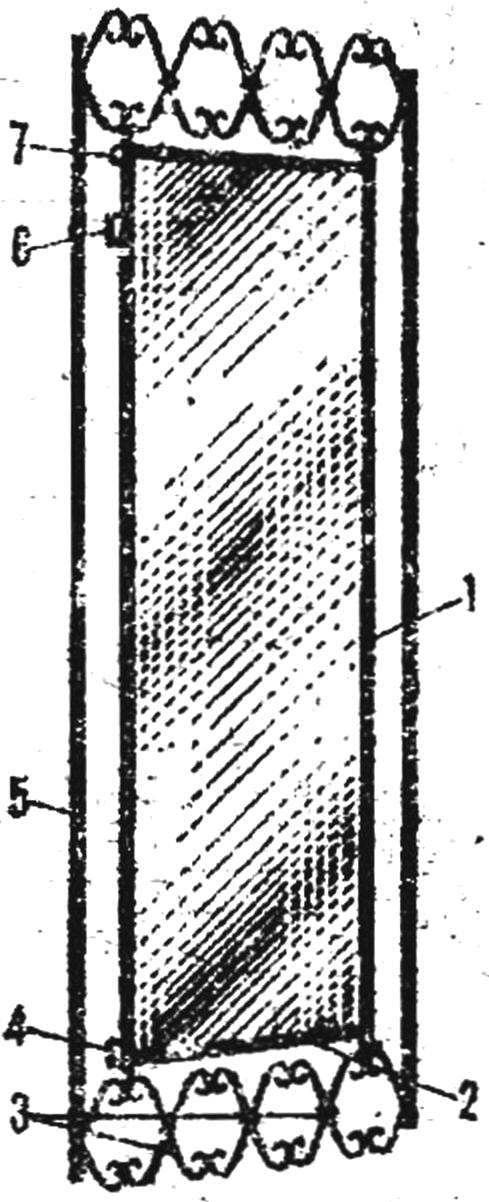

Manufacturer. Terminals 1 and 4 are sawn off from the profile, a preform ring 7 — rod, after crooking his late assistant device. For the manufacture of decorative items 3 need to make a template of 1:1 of thin cardboard (the radii are arbitrary), and then put it on a sheet of colored metal outline needle for marking and cut. After processing the edges of the detail bounces with a hammer in a cold state and is formed so that the internal rays she lay down on the frame, and under it.

After cutting out parts 2,5,6 processing the edges with a file, while the squares 5 is formed ornament. Degli 8 and 9 are holders of a mirror. They saw off from the strip and bent and the grip of the hammer.