There many important components and parts to trace in the box? Yes, almost everything — so I will answer any, even the young athlete. But surely he’s really isolated from all the other current collector. It is from that little detail most of all depend on the reliability and stability of the micro-car, only on the most difficult parts of the route, and therefore, a high result.

There many important components and parts to trace in the box? Yes, almost everything — so I will answer any, even the young athlete. But surely he’s really isolated from all the other current collector. It is from that little detail most of all depend on the reliability and stability of the micro-car, only on the most difficult parts of the route, and therefore, a high result.

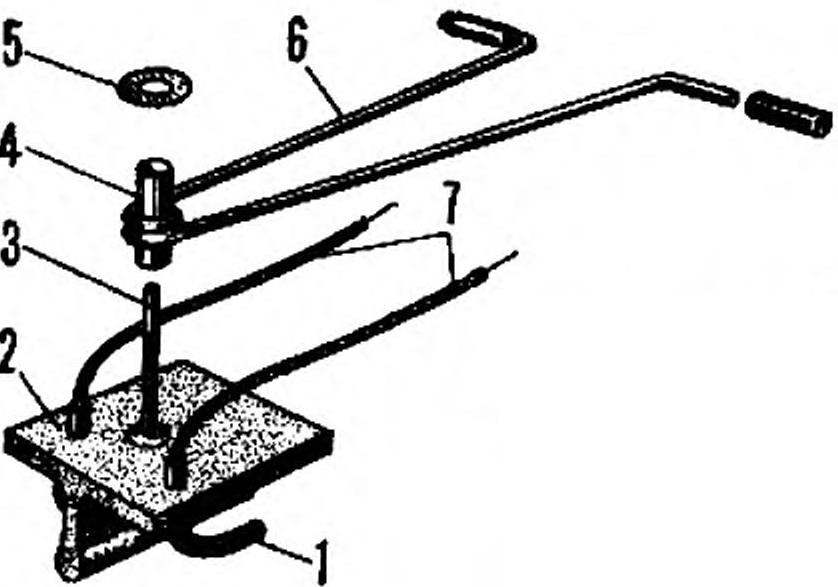

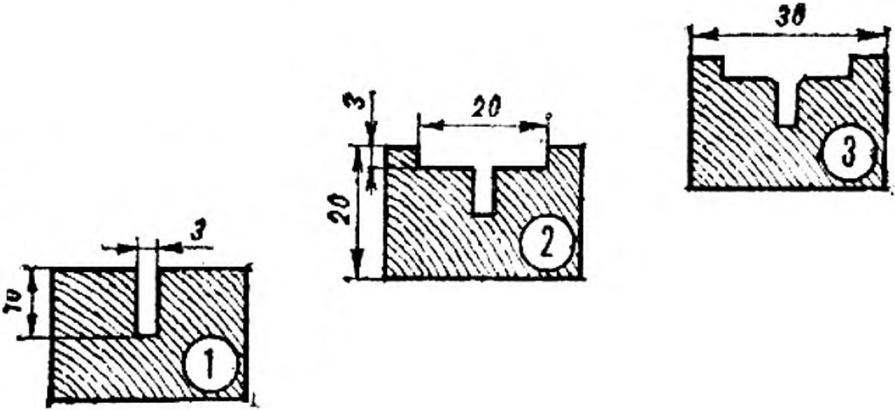

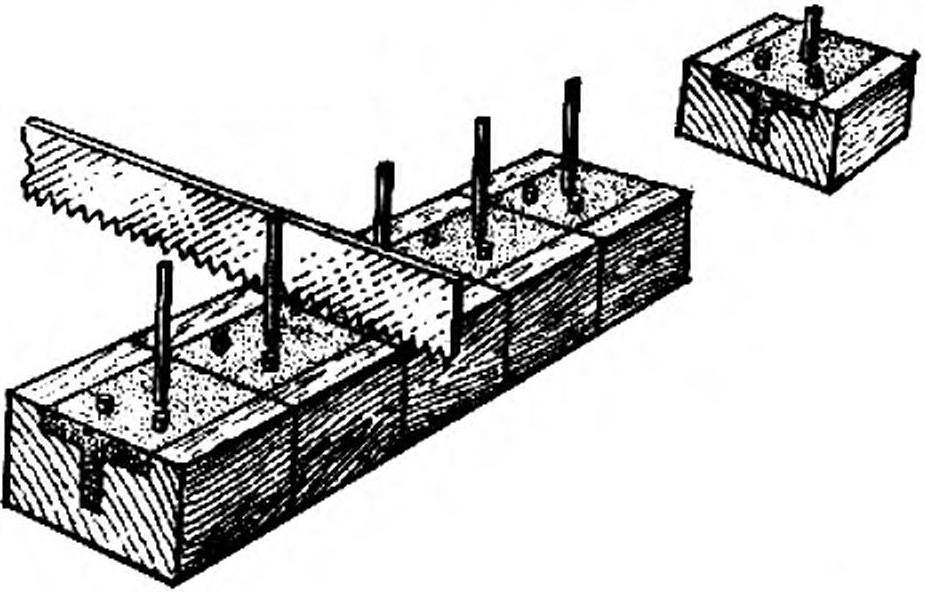

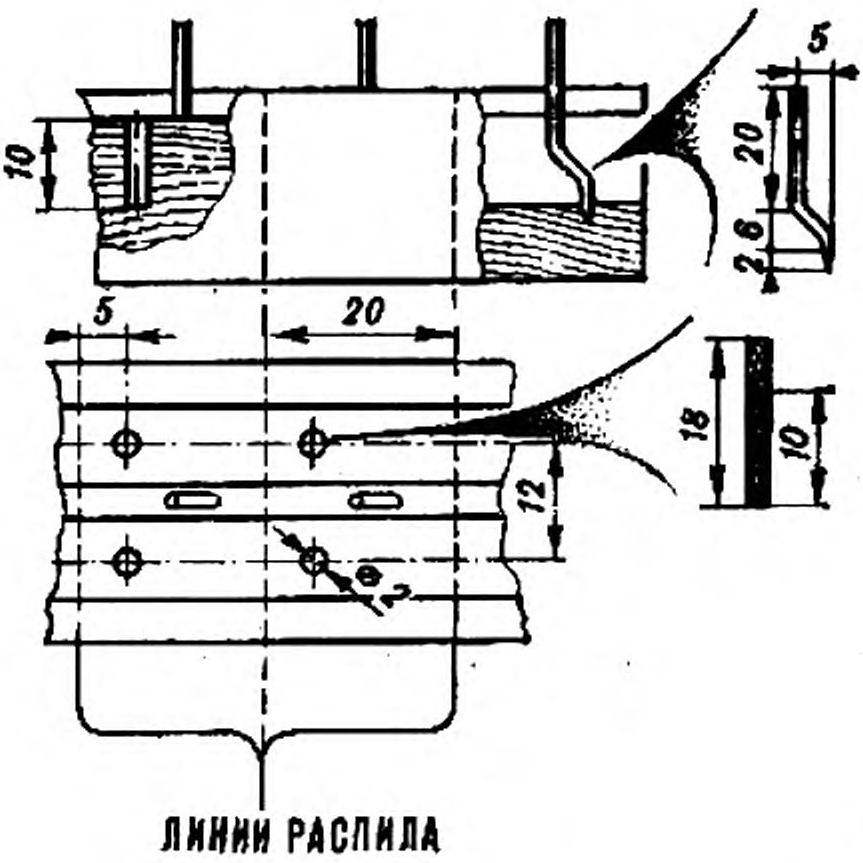

Despite the seeming simplicity of the form of the accuracy requirements of the current collector is very high. The hands of boys, not yet accustomed to the instrument, not always ideal to fine detail. To facilitate this work, in the school circle autocrossover modeling of the city of Rivne are using “mass production” of slip rings. In the wood section 20X30 mm milled longitudinal groove. His profile matches the cross-sectional shape of the current collector, the bar length is determined by the maximum feed of the machine. After mark and drill holes under the tires of the current collector, which are made of braid shielded wire. Cleaning the groove with sandpaper and evenly greased graphite composition, prepare the tires, soaking them in the same composition, and set in the prepared holes. Exactly in the middle of the channel are fixed pins. They belong to the axis of rotation of the collector and its fittings. The pins are made of steel wire, Ø 1— 1.5 mm and bent in the form shown in the drawings. To facilitate the installation of these parts and the channel bar of the lower part sharpened to a tip. The groove is filled with epoxy resin from flowing it protects the clay “cap” the ends of the bar.

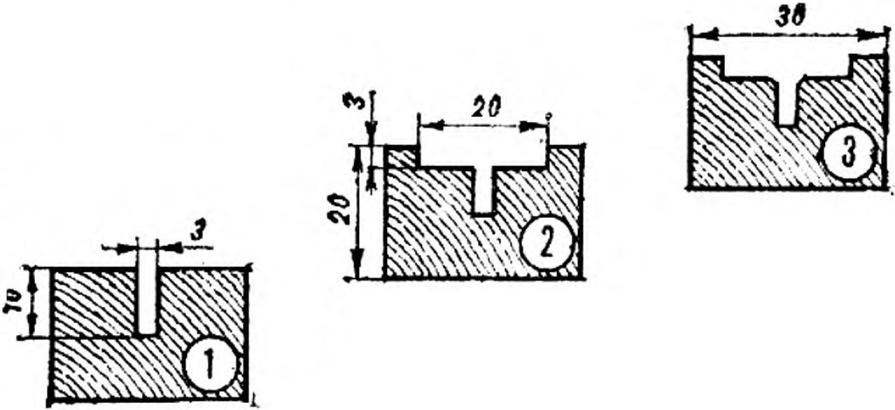

The current collector highway in the box:

1 — bus, 2 — body, 3 — pin, 4 — hinge, 5 — washer 6 — plug, 7 — a current-carrying conductor.

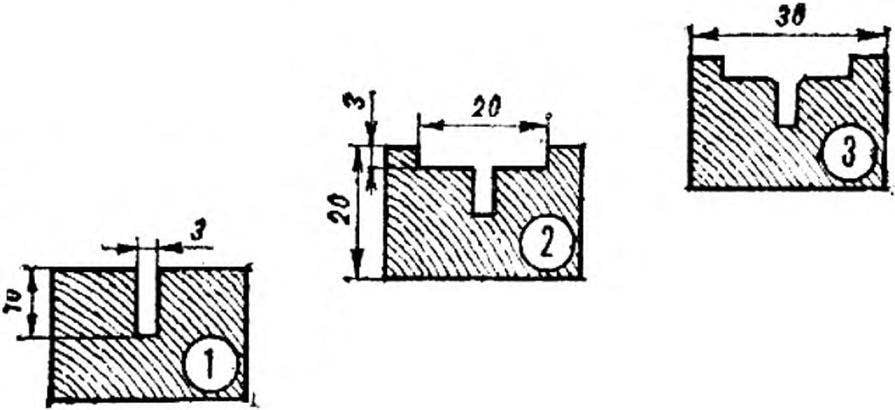

Milling of a groove in a wooden form. The numbers show the sequence of operations.

Cutting the workpiece with the form on individual items.

The layout of the holes in the wooden form, the installation of the pins and slip the tires.

After complete curing of the resin casting with a shape cut with a hacksaw or jigsaw to the same part, with the current collector and tires neatly cleave the wood. Just bring the plastic parts with needle files, solder wires to the motor.

V. PROKOPOVICH, V. BUBALO, Rivne