Modern structural materials greatly expand the manufacture of furniture for individual projects. Frame system, designed by the firm of Mr. Doors, allow homebrew to create cutting-edge environment for all living areas — hallways, living rooms, nurseries, closets, offices, home offices. The main advantage of such furniture designs — simple and fast installation, the possibility of moving and adding shelves, modules for different purposes, lamps and clothes hangers.

Durable and lightweight aluminum construction extends the setup and installation of furniture in various variations: “floor — ceiling”, “floor — wall”, “floor to floor”. Examples of designs submitted samples of a frame of the furniture exhibited in numerous exhibitions and in specialized directories indicate that of these systems because of their simplicity and accessibility, can be manufactured and home-made furniture options.

Here are the approximate schema and dimensions of such structures for the manufacture of their own hands. They are based on metal racks of tubes of circular or square cross-sections and plane — of the furniture Board (or chipboard).

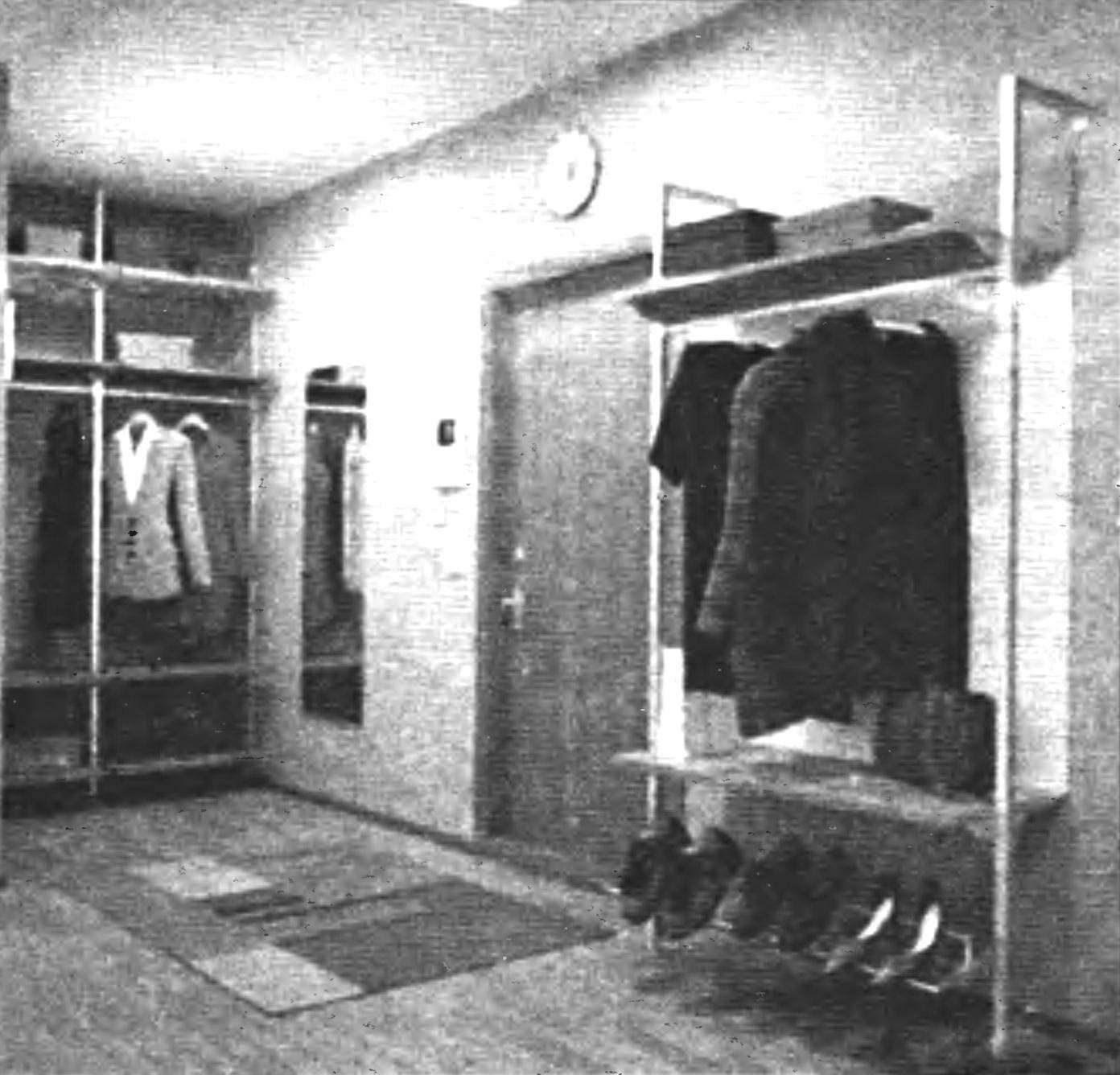

Entrance hall-based stands can be made in two separate versions.

On the top left picture is the rack on two falshstena and the Central front of the “floor — ceiling”. Right — hanger and stand for shoes based on stands “floor — wall”. Consider these structures in more detail.

Open hanger

Option stands “floor — wall” (Fig.1) looks more solid, although the execution is even simpler than the “floor — ceiling”. For this hallway, you will need two steel square tube (30×30 mm) with a length of about 2200 mm In the upper part they have after sawing as shown in the figure, is formed l-shaped strut, terminating in small cuts that allow to bend the lugs for mounting racks to the wall.

Between the uprights there are two shelves on the distance to place between them hanging on hangers clothes. Upper shelf that is narrower, designed by hats. Under it between the uprights is mounted a tubular cross member under the shoulders. To the ends of the cross member tightly inserted wooden plugs, in which through holes in the rack are the mounting screws that hold the cross member (which gives additional rigidity of the entire structure).

Fig. 1. Hallway of the stands of the “floor—wall”:

1 —front (square); 2–the reference triangle; 3—lower (large) shelf; 4—screen (hardboard): 5—upper (narrow) shelf; 6—suspension for shoes

At the bottom between the uprights is attached a wider shelf under the bags and clothing accessories. The reliability of the support of both flanges is provided with triangles of duralumin plates with a thickness of about 5 mm, having at the end of the hook and the ends of the spikes: they are introduced in the corresponding holes in the uprights and securely hold the support triangles.

At the lower ends of suspension struts is installed to the Shoe. It is performed, as shown in the figure, from the thick steel wire, the ends of which have fastening bends up and are inserted in the holes prepared for them in the racks and thus hold the hanger.

Rack-rack

Another lightweight design hallway — pillars-type “floor — ceiling” (Fig.2) — characterized primarily by the fact that they applied for tubular profile does not undergo any changes because it is used in this case other mounting method: vraspor between the ceiling and the floor.

So, you will need three identical rack (square tube 30×30 mm): main (Central), which will abut the ceiling, and two auxiliary side, playing the role of just the supports for the shelves.

On the Central front top-set spacer hub — bolt with nut and a wide washer that bears on the nut with the bolt screwed her head up. If you now start to Unscrew the bolt it will hit the ceiling and will secure the strut between the ceiling and the floor. To the floor under that kind of pressure is not affected, under the rack is placed a die from a Board or plywood. The same dice have and side rails.

Fig. 2. Rack on racks “floor—ceiling”:

1—lateral (accessory) stand; 2—shelf; 3—the support triangles; 4 wide washer; 5—nut; 6—spacer bot; 7—supporting pins; 8—die-stand; 9—Central (resistant) stand; 10—rod for hangers

Shelves that are installed between the racks, can be chopped from furniture Board, thick plywood or particle Board. In combination with the racks they have the proper cutouts, and the shelves are set here, as in the first embodiment, the triangular base plate. However, placing them on the racks has its own characteristics. To provide the necessary stability of the shelves, the backing plates are mounted on the uprights multi-directional: that is, from one edge of the shelf to prop up her plate with its angle directed away from the wall, and on the rack with the other hand in the opposite direction. If such strengthening of the mounting shelves are not required — they can only do cutouts under the rack and threaded into the holes of the uprights of the supporting pins of the metal rod.

On the wall behind each of the designs and the hall is attached a sheet of hardboard, plastic or bamboo blinds for protection and walls, and clothing.

If necessary, both designs can be painted: metal parts — a nitro lacquer in black or brown, and the shelves, if they are made of plywood or chipboard, enamel or dark furniture Polish.

Recommend to read DE HAVILLAN DH.82 “TIGER MOTH” Developing the concept of training plane DH.60, John. De Havilland has created a new aircraft of the same class - DH.60T. He was distinguished by a reinforced airframe, a modified... EPHESUS FOR STRETCHERS No construction can not do without a stretcher, you have to use them indoors. Introducing heavy burden on the narrow stairs, passing through the doorway happens to be caught with a hand...  Modern structural materials greatly expand the manufacture of furniture for individual projects. Frame system, designed by the firm of Mr. Doors, allow homebrew to create cutting-edge environment for all living areas — hallways, living rooms, nurseries, closets, offices, home offices. The main advantage of such furniture designs — simple and fast installation, the possibility of moving and adding shelves, modules for different purposes, lamps and clothes hangers.

Modern structural materials greatly expand the manufacture of furniture for individual projects. Frame system, designed by the firm of Mr. Doors, allow homebrew to create cutting-edge environment for all living areas — hallways, living rooms, nurseries, closets, offices, home offices. The main advantage of such furniture designs — simple and fast installation, the possibility of moving and adding shelves, modules for different purposes, lamps and clothes hangers.