I wonder how would the heroes of Ilf and Peter, if he knew that the treasures are in the chair, made for one of the modern furniture factories in Moscow m taken out of the context in selling the amount of one million ekzemplyarov! But the most annoying is that even such elementary and simple furniture is not enough, and the price on it jumped to fantastic quantities. “M-K” constantly tells its readers, with minimal cost, but and the same time original and tasteful to organize your life is to make furniture with his hands. And not sang to call the recommended options, and take them only as a basis, modifying and transforming under Soi conditions and possibilities.

I wonder how would the heroes of Ilf and Peter, if he knew that the treasures are in the chair, made for one of the modern furniture factories in Moscow m taken out of the context in selling the amount of one million ekzemplyarov! But the most annoying is that even such elementary and simple furniture is not enough, and the price on it jumped to fantastic quantities. “M-K” constantly tells its readers, with minimal cost, but and the same time original and tasteful to organize your life is to make furniture with his hands. And not sang to call the recommended options, and take them only as a basis, modifying and transforming under Soi conditions and possibilities.

For many years the “Club house masters” has become a real encyclopedia, “digging” in which you can find many the various sofas, cabinets, chairs, walls, tables, and a huge number of other necessary in everyday life. Naturally, most of the “quiet development designed for repetition at home, when love La tinkering is under the hands of only the most simple rasprostranennye tools. But you don’t want to do something unusual, different from the usual modern “sharp corners”.

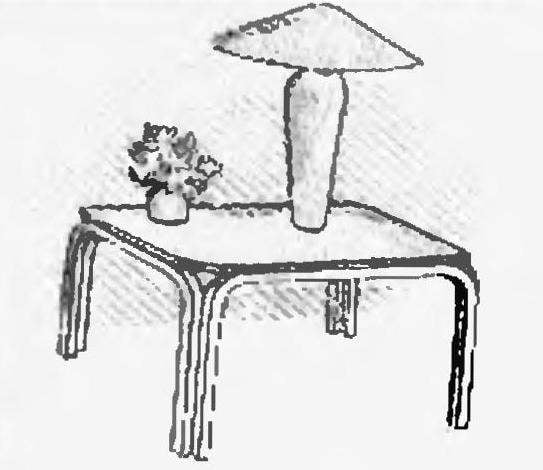

Those who share this point of view, the proposed is for the initial PA to try your hand in making a very original furniture set of coffee table and chair. Their main difference — the presence of curved elements. Such forms with soft silhouettes emphasize the beauty and plasticity of the wood give the interior comfort. If someone pomareda at first glance that to make such designs difficult^ you can calm down — and the simple things singing will make you feel like a master of almost any citizen, not to mention the rural people who work with wood “in the blood”. In addition, the materials used are the most cheap and available today from everything you can think of.