The cross section for the passage of smoke shall not be smaller than the area of brick laid flatwise. Heat loss when the furnace is inevitable (the temperature of smoke is approximately equal to 50 0C) and in compliance with all terms of the efficiency of the furnace will be about 77 percent.

Standard doors for the furnace (Fig. 2) need to Refine: cook them under boxes of 4 mm iron on the width of the brick; to boxes of welding strip (also from 4-mm steel) for anchoring them to the masonry. Box furnace door and blower is a better weld with one unit.

The grate of the furnace, if you want to save up to 30 percent of the fuel, it is better to make yourself, especially if coal as fuel. The fact that the standard grate is too wide a slit through which part of the coal just falls. A good grate is obtained from sieves of the machines or mining machines. The thickness of the sieves of 5 mm, the hole diameter is also 5 mm (similar to standing in forging furnaces). To the grate will have a bottom weld cooling fins of the rod with a diameter of 16 mm (Fig.H), which both will and power framework. As shown, this grate is longer than standard. It does not allow the coal to ignite strongly, and achieved the necessary resistance to air flow as it passes through the ash pit and the grate. Coal when it burns and burns to the ground, giving all the warmth of the upper iron plate, and she immediately transfers heat to the room air.

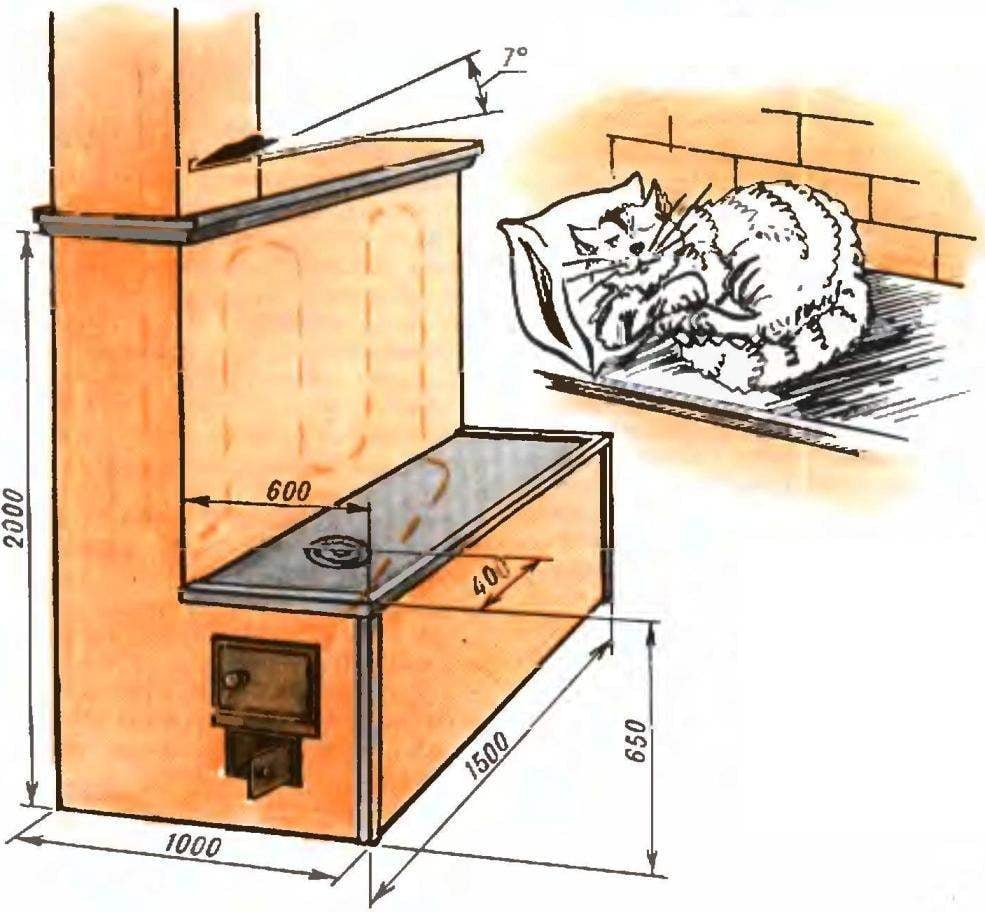

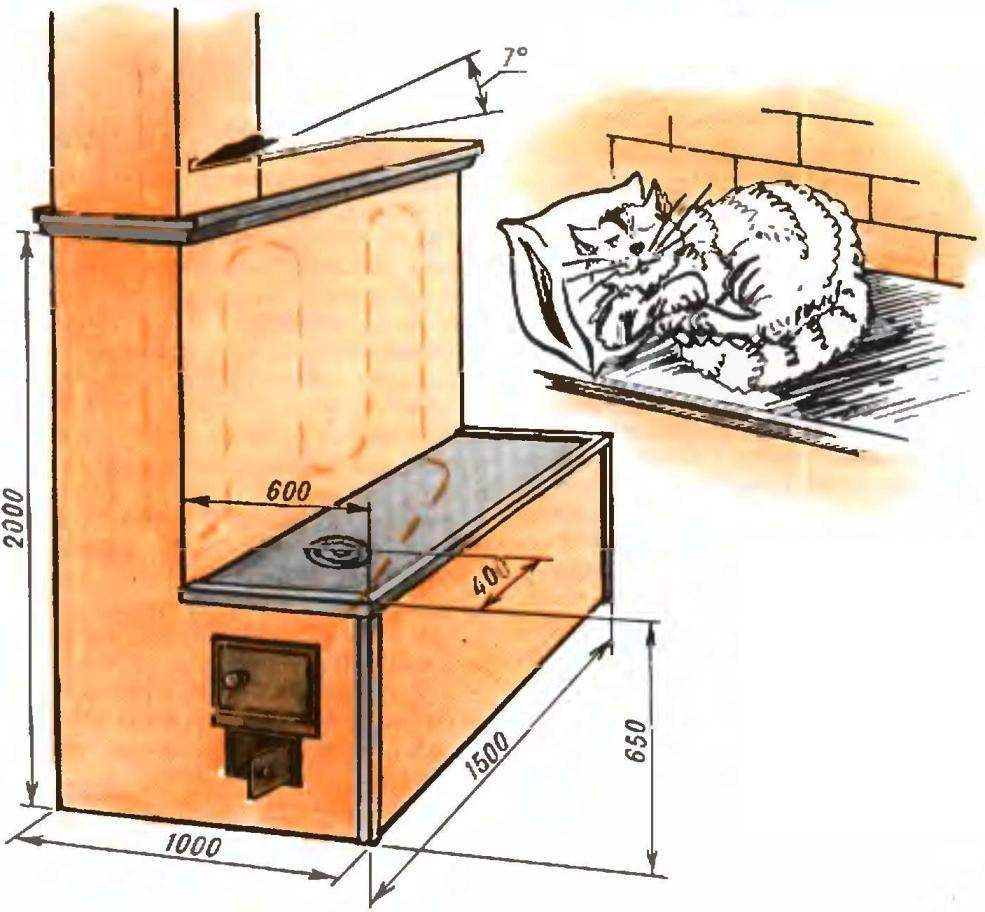

Figure 1. It looks like the stove-couch.

Fig. 2. Box podvelka to the furnace:

1 at podvelka; 2 — box blower; 3 —fire door, 4 — box of the furnace; 5 — band mortgages; 6 — wire mounting.

Fig. 3. The grate of the furnace:

1 —mesh; 2 — frame of steel rod.

The furnace (Fig.5) it is necessary to put a refractory brick on an edge. Qualitatively it is impossible to fold without cutting bricks. He is well-cut vulcanicum around, impaled on the shaft of the motor.

Masonry wells (revs smoke) being a brick on an edge, and only the face part of them laid a brick flatwise. The sides are held together with pins (Fig.6); the latter are cut into pieces of 3-4 mm wire and bend easily with pliers. When laying the upper layers of the bricks press down studs, and securely tightening the sidewalls of the wells. This clutch with studs will prevent the cracks already finished the oven at any heat.

The valve in the pipe must be installed with a slope inwards at an angle of 7°. Ego will prevent leakage of condensate and melted in the tube snow on the whitewashed wall ovens — all the dirt and soot will flow down inside of the chimney and further the furnace will evaporate. The use of double dampers for a furnace is not justified. The fact that the heat from the house goes mostly through the Windows and walls. Therefore, it is sufficient to simply no heat loss.

Fig. 4. Treatment plant chimney hole kolodeev (revs):

1 — hole; 2 — refractory brick; 3 — steel strip.

Fig. 5. Furnace.

1 — door podavala; 2 — fire door; 3-plate; 4 burner; 5 — burner: 6 — chimney.

Fig. 6. Masonry chimney wells:

1 — plate; 2 — the wall of the wells; 3 wells (rpm); 4 — stud; 5 — Highlander wells.

For cleaning ovens from soot left three holes in the bottom of the rpm (Fig.4). On top they are covered with strips of 4 mm sheet steel. To close those holes better refractory brick: the color they will be easier to find in a few years to open for removal of soot.

And finally, the roof of the oven. She gives them scraps metal strip 4 mm thick, and the top—two or three layers of brick flat for formation of the gusset plate of the furnace.

In conclusion, open secret: the furnace-bed — Chinese style. It is famous even that is enough to heat it two or three Newspapers or an old magazine — and even in cooler weather you can sleep in warm for 4-5 hours!

V. RADKOV, Naberezhnye Chelny

Recommend to read HOLOCAMERA — ANY Because of the deterioration of the old Velocimetry often have to fix. The new find does not always succeed there, but another size of industry and trade not able to keep up with... SWEDISH MAIN BATTLE TANK After world war II in tank to establish a relatively strict classification. Steel tanks called armored combat vehicle on tracks with a cannon placed in a rotating turret....  Oven is better to put. Built by the owner, it will serve him throughout life; only once in 7-8 years, it will have to be clean (soot typed 2-3 buckets, because the rate of increase of its thickness on the surface of the chimney up to 2 cm per year). So, oven-shield (Fig. 1). It has five wells and five turns of smoke. More of them should not do: be a bad pull, because the pipe needs to heat up — then it works like a hood (if for this purpose I had to set the blower motor, the power it needs to achieve 0.2 kW). Three turns too bad — large heat loss.

Oven is better to put. Built by the owner, it will serve him throughout life; only once in 7-8 years, it will have to be clean (soot typed 2-3 buckets, because the rate of increase of its thickness on the surface of the chimney up to 2 cm per year). So, oven-shield (Fig. 1). It has five wells and five turns of smoke. More of them should not do: be a bad pull, because the pipe needs to heat up — then it works like a hood (if for this purpose I had to set the blower motor, the power it needs to achieve 0.2 kW). Three turns too bad — large heat loss.