Any front panels made of aluminum alloy are easily amenable to decorative processing. For example, after drilling holes in them, these parts can first be subjected to anodizing, and then painted. Both processes do not require special equipment and can easily be performed at home.

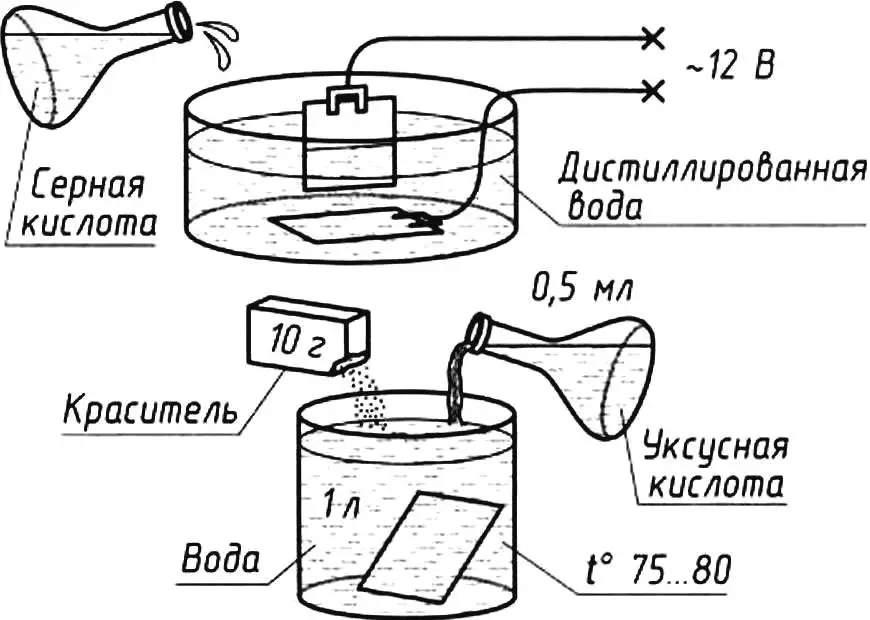

Small panels are anodized in a glass cuvette. Distilled water is poured into it, and 200 ml of technical sulfuric acid is added for every 800 ml of water. The panel is clamped at the ends with U-shaped brackets and lowered into the electrolyte. Above it, on suspensions, a duralumin plate-electrode is placed (this can be a second panel to be anodized). The brackets and suspensions are made of duralumin. Flexible insulated wires are connected to the plates from a step-down transformer with an alternating voltage of 12 V.

It must be taken into account that duralumin comes on sale clad (with a thin layer of aluminum on the surface) and unclad. Panels made of clad duralumin are anodized at a current density of 1.5 A/dm2 and kept in the bath for 15 minutes. Panels made of unclad duralumin are anodized at a current density of 2.5 A/dm2 and kept in the bath for 25 minutes. Before anodizing, the panel must be well degreased with acetone or gasoline, washed in a solution of laundry detergent, and then in distilled water.

The anodized panel is dyed with a regular aniline dye intended for processing woolen fabrics. The prepared solution should have a temperature of 75 – 80°C and contain 10 g of dye and 0.5 ml of acetic acid per liter of water.

The holding time is from 5 to 10 minutes, depending on the desired color saturation. The coloring must be fixed. For this, the panel is kept for about one minute in boiling distilled water. To protect the surface from mechanical damage (scratches), it is useful to coat the panel with colorless furniture varnish NC-228.

V. IVANOV