Nowadays the amount of paper waste has increased sharply, mainly due to “disposable” printed matter: besides newspapers and magazines, mailboxes are filled with countless promotional leaflets, various election campaign materials and the like—all free of charge. It would be a shame not to put such gifts to use.

The “Master” club figured this out long ago and developed a technology for making fuel briquettes from paper pulp (approximate dimensions 290×170×100 mm). Such a briquette burns for about two hours, and its calorific value is twice that of coal. It is also important that after burning an ordinary newspaper about 80% ash remains, whereas a briquette leaves only 5%.

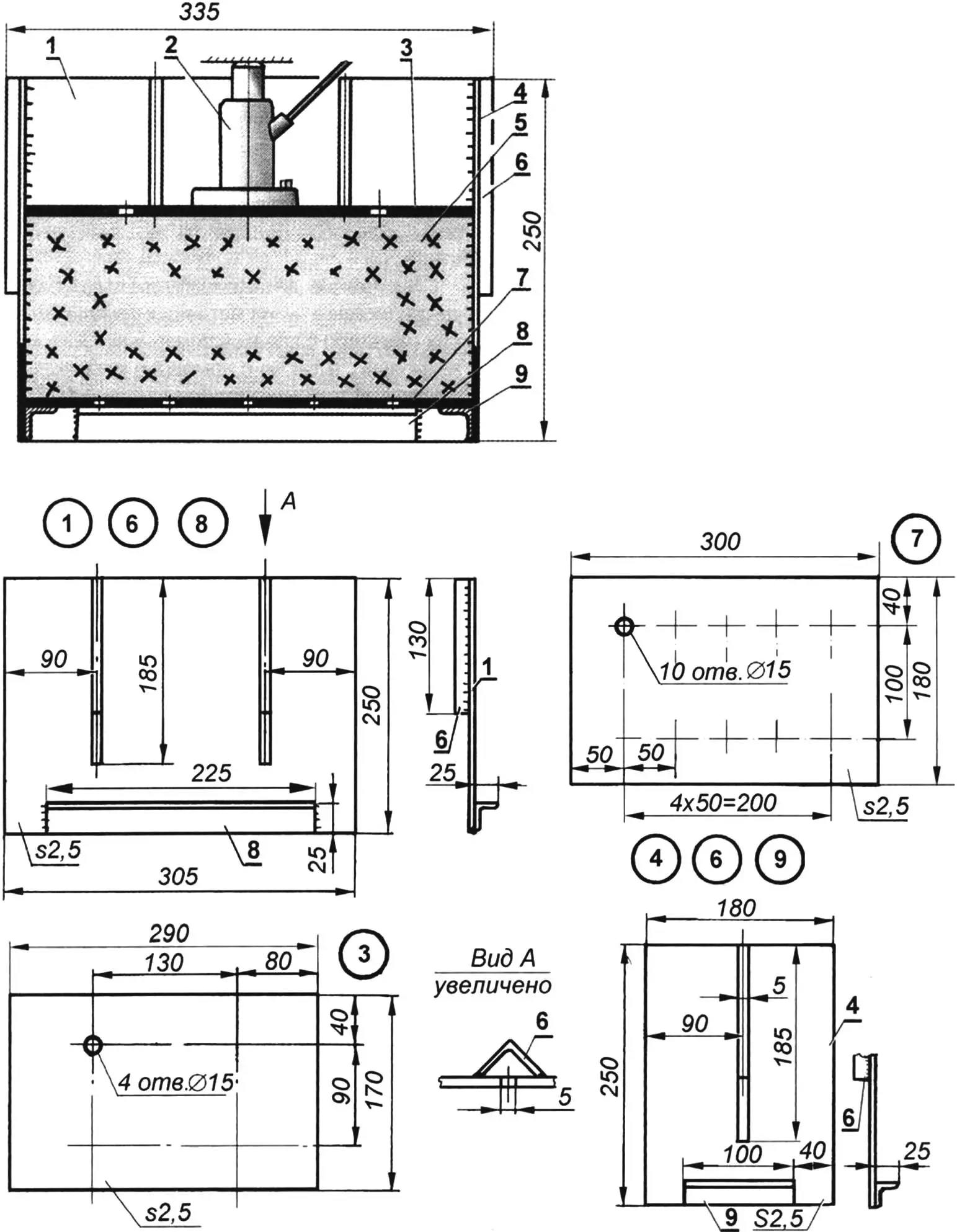

To obtain paper “firewood” you need to build a simple press, one version of which is shown in the drawing. Of course, the dimensions of the structure can be adjusted depending on the size of your heating appliance.

1 — large wall (steel sheet s2.5; 2 pcs.); 2 — jack; 3 — lid (steel sheet s2.5); 4 — small wall (steel sheet s2.5; 2 pcs.); 5 — paper pulp; 6 — wall reinforcement (angle 10×10; L130; 6 pcs.); 7 — bottom (steel sheet s2.5; 2 pcs.); 8,9 — bottom brackets (angle 25×25; 2 pcs. each)

The press body consists of two large and two small walls, a lid and a bottom. Holes in the latter are drilled to drain moisture. For the same purpose, slots are made in the walls (round holes would hinder removal of briquettes from the press). So that strength and rigidity of the walls are not compromised, the slot areas are reinforced on the outside with 10×10 mm angles. To mount the bottom, 25×25 mm angle brackets are welded to the lower part of the walls; the walls are welded into a rectangular box.

The force element of the press is an automotive jack. When making briquettes, the paper pulp (newspapers, cardboard, etc.) is shredded and soaked for 10–12 hours. Then the press box is fitted with support angle brackets, the bottom is placed on them, then the wet paper pulp, and on top the lid, on which the automotive jack is set. Under its action, water is squeezed out of the paper pulp through the holes in the bottom and lid and through the slots in the walls. After the force is released, the box is turned over and the paper briquette is pushed out. Drying time is 5–7 days, after which the briquettes are ready to use.

«Modelist-Konstruktor» No. 2’2006, S. MOLOTKOV