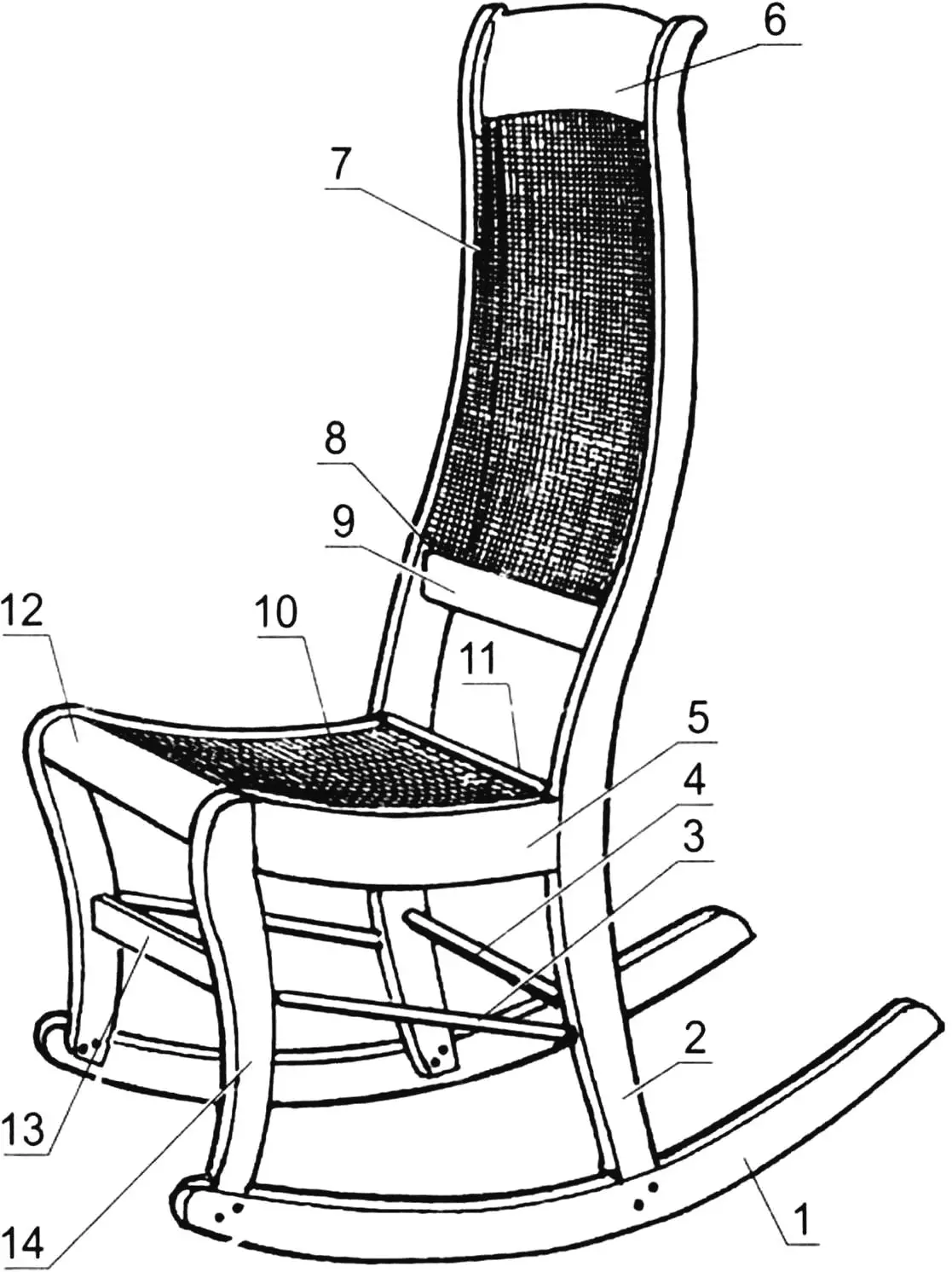

Modern rocking chairs – something’s wrong with them! Made in a lightweight version, they practically lack moment of inertia. The proposed design does not have this drawback. It is assembled from sufficiently massive wooden parts, which contributes to an increased number of swings from a single push. At the same time, the chair does not look overly heavy, all its parts have a beautiful curved shape, dictated not only by the aesthetic requirements of the retro style, but also by ergonomics that ensure maximum comfort.

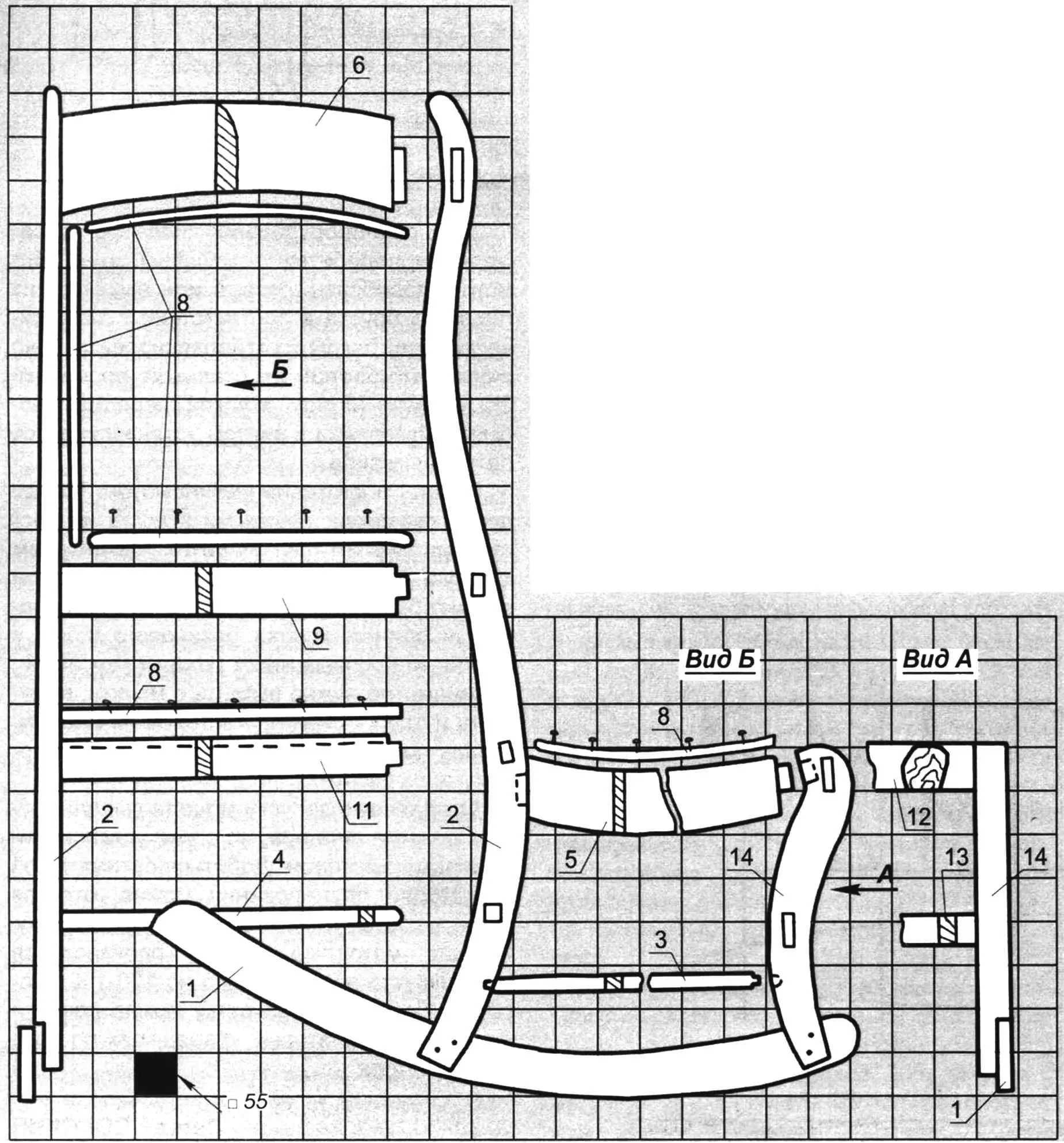

For the manufacture of load-bearing elements, thick boards (up to 40 mm) and bars are used. The backrest posts simultaneously serve as rear legs, since they are made as a single part of the backrest and seat. It is not difficult to obtain the figured shape of the posts: the part configuration is transferred onto the board surface using a scale grid, which is then cut out with an electric jigsaw or hand saw. On the resulting blank, according to the markings, mortises are made for tenon joints with the backrest crossbars and the lower part of the post, as well as with the seat parts. Then holes are drilled for furniture bolts, with which the post is attached to the floor arcs. The latter can be made from thinner boards, as they are subjected only to vertical loads. In the arc blanks, holes for connecting bolts are also drilled according to the markings.

The chair actually has two legs – the front ones. Their configuration practically repeats the lower part of the posts, but as if in a mirror reflection. This shape provides the necessary support and guarantees strength when rocking. In the upper and middle parts of the legs, mortises are prepared for tenon joints with the mating seat parts and the side cross stretcher, and in the lower part – holes for bolts to connect with the floor arcs.

1 – floor arc (board s15 mm, 2 pcs.); 2 – posts (board s40 mm, 2 pcs.); 3 – side stretcher (slat 20×20 mm, 2 pcs.); 4 – lower crossbar of posts (slat 30×30 mm, 2 pcs.); 5 – side seat rail (board s40 mm, 2 pcs.); 6 – top of backrest (board s35 mm); 7 – mesh-woven 550×495 mm); 8 – mesh mounting slats (slat 20×20 mm); 9 – backrest crossbar (board s20 mm); 10 – seat mesh (495×440 mm); 11 – rear seat rail (board s40 mm); 12 – front seat rail (bar 60×60 mm); 13 – stretcher (strip 30×20 mm); 14 – front leg (board s40 mm, 2 pcs.)

The main rails connect the front legs to the posts. They have a slight curve that provides the seat with a comfortable shape. Flat tenons are prepared at the ends of the rails for connection with the legs and posts. Below are the side stretchers – these are bars or round rods connecting the legs to the posts.

The crossbars include all other parts connecting the posts and legs. The posts have two of them. The upper, wide one, and the middle one – narrower, have a slight curve. The concavity of the middle part of the crossbars can be obtained by planing these sections with a small plane and processing with a draper file. The third crossbar of the posts is part of the seat frame. It has no curve and ends on both sides with a flat connecting tenon. The lowest crossbar of the posts is intended for fastening that part of them that serves as the rear legs. This can be a bar of small cross-section or a round rod, connected to the posts with a simple tenon.

For the front legs, the upper crossbar is an element of the seat frame. This is a bar, the front edge of which is smoothed with a plane to obtain a rounded front face. At the ends – flat tenons for connection with the legs.

Approximately the middle of the legs is connected by a flat stretcher also with tenoned ends – for the mortises on the legs.

Before assembly, the parts are carefully sanded with “sandpaper”. As already noted, almost all parts of the chair are connected to each other with a simple flat tenon (using glue). The strength of the joints will depend on the thoroughness of execution of both the tenons themselves and the mortises for them.

Finally, a strong mesh made of natural or synthetic materials is nailed to the backrest and seat areas.

Yulia CHERNYSHOVA, designer