Modern rocking chairs offered by the trade, are usually in the Lite version, and therefore almost no moment of inertia during the swing. In contrast, the design proposed by the Hungarian magazine “Earmaster”, going from a fairly massive wooden parts, according to the chair the required weight contributing to the increased supply of swings, repeated by one push.

Modern rocking chairs offered by the trade, are usually in the Lite version, and therefore almost no moment of inertia during the swing. In contrast, the design proposed by the Hungarian magazine “Earmaster”, going from a fairly massive wooden parts, according to the chair the required weight contributing to the increased supply of swings, repeated by one push.

With this purpose for the manufacture of the main load-bearing elements of the chair uses thick boards (40 mm) and bricks. However, the chair does not look heavy due to the fact that all items have a beautiful curved shape that is dictated, however, not only aesthetic, but also ergonomic for comfort rest.

The seat base — racks back and front legs connected with the outdoor wires. Four cross-beams form the frame of the seat. The reference plane of the back and seat mesh panels nailed in tight taut with rods and nails.

Stand back

They play both the role and back legs while they run as a single piece back and seat.

Curly-shaped racks to easy. On the surface of the Board in grid is transferred in the General configuration details, and then cut using the jigsaw or the narrow hand saws.

On the resulting workpiece in accordance with the marking performed housings shipovoe connection with the cross members of the back and bottom of the rack, as well as details of the seat; then drilled holes for the furniture bolts, with which the rack is mounted on the outdoor arches.

After completion of these operations with both racks you can start making other parts of the chair.

Arc

Outdoor arc can be made of thinner boards, because during operation are subjected to a vertical (that is, only on their edges) loads.

To obtain the necessary curvature of the workpieces Doug will help again driven grid, which is easy to transfer onto the prepared surface of the Board. If the width of the available boards for this purpose is insufficient, it is possible to unite the two boards, docked their lateral edges using plug-in round thorns (nails) and glue (carpenter’s, PVA). Sawing is the same tool that is used for the stands.

In the blanks Doug is also on the markings of drilled holes for connecting bolts furniture.

Legs

Actually the legs of a chair two front. I wonder what their configuration is virtually identical to the lower part of the stands, but as if in mirror reflection. This form provides the necessary focus — and thus to guarantee the strength during rolling, and also serves as a unifying outward sign to the bottom of the chair.

The legs are cut similar to the previous parts using transferred to the surface of the grid.

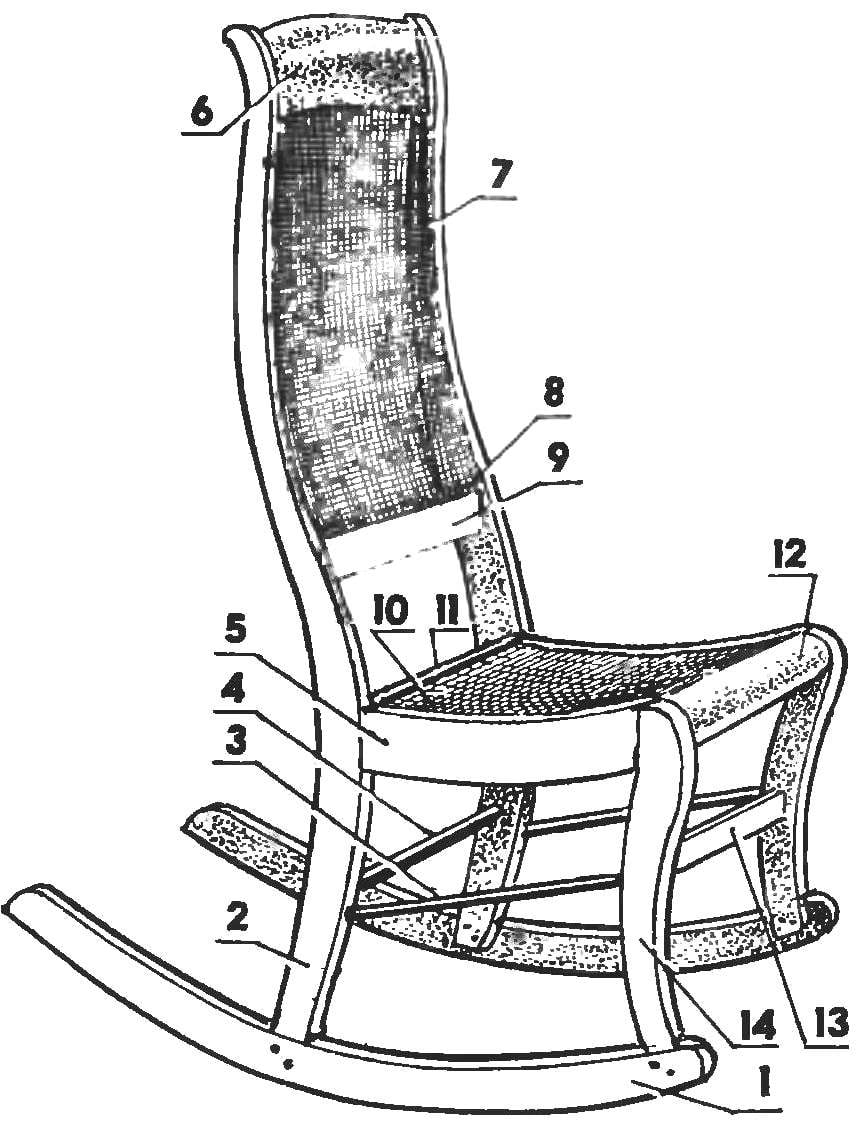

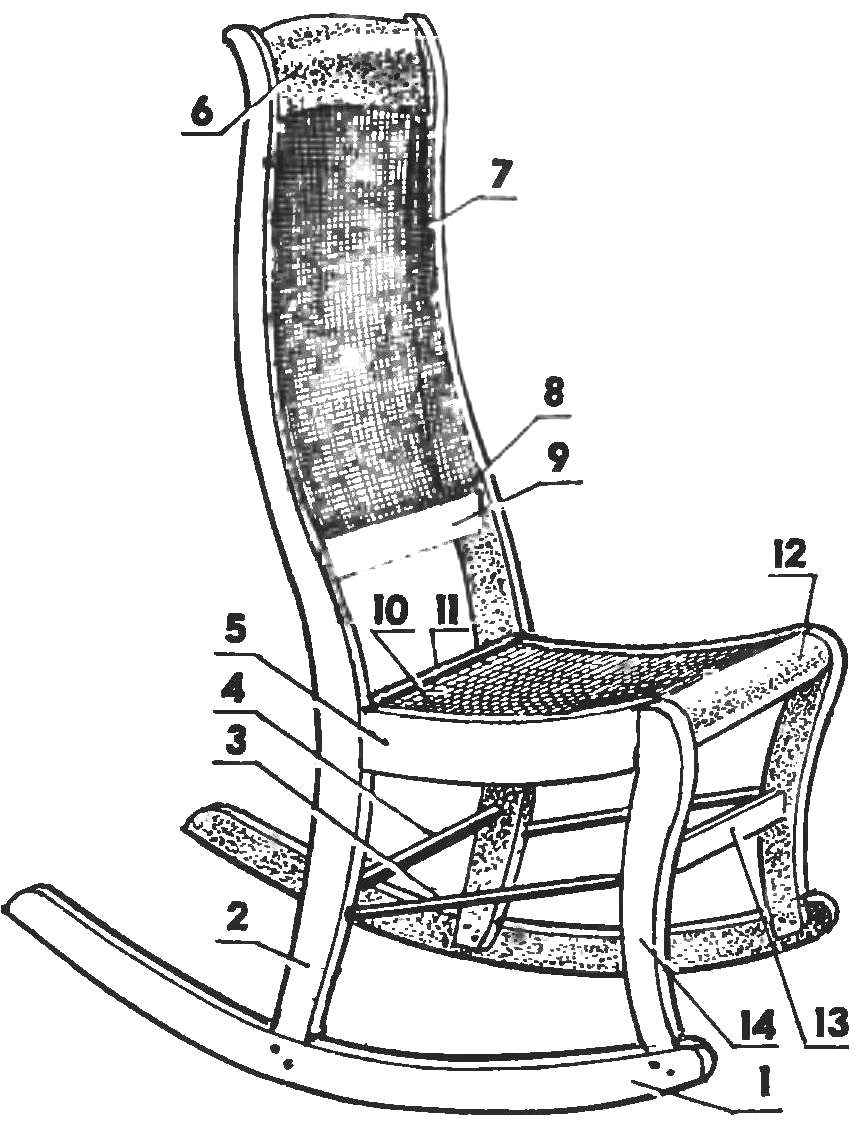

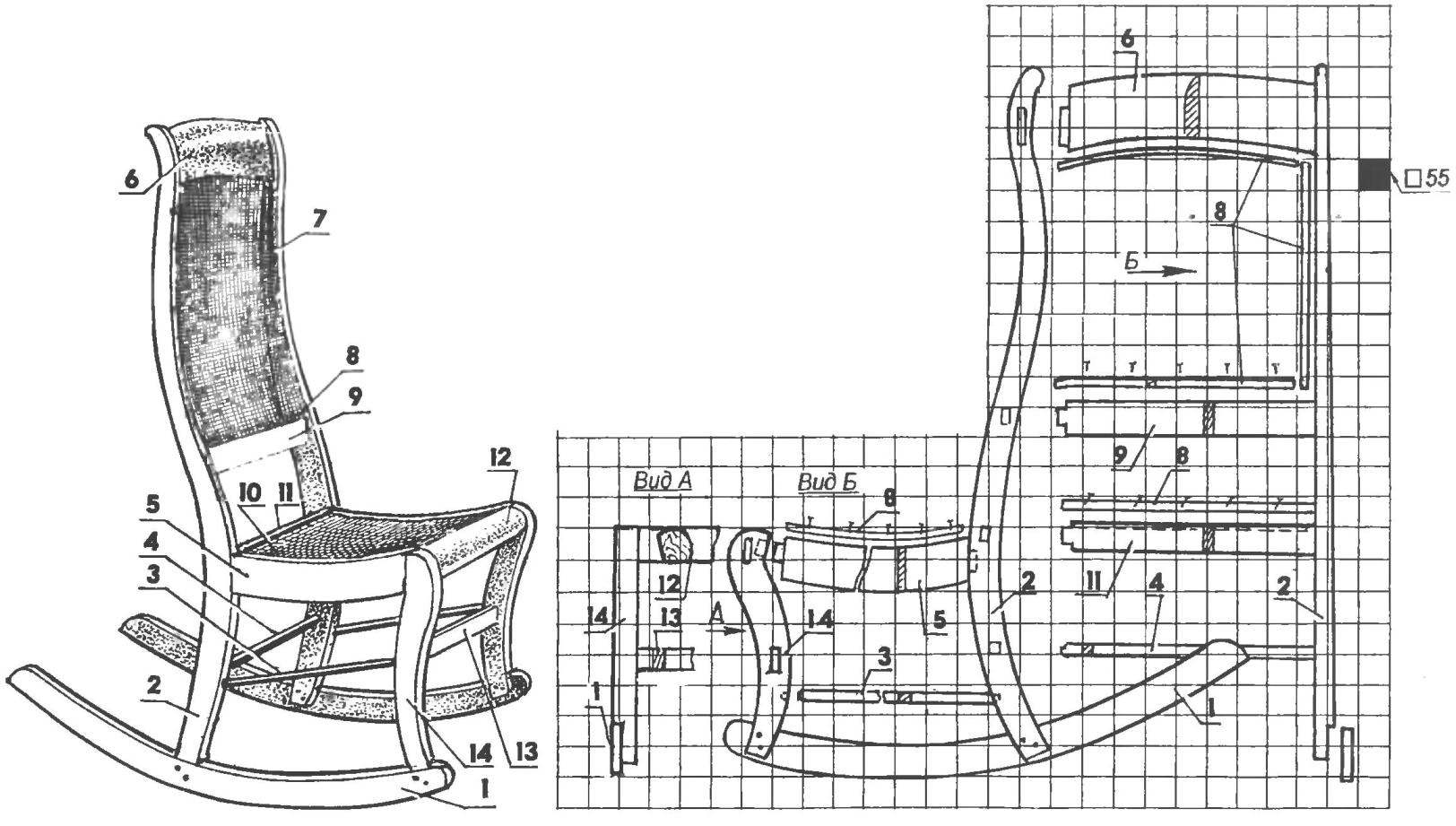

Rocking chair:

1 — outdoor arc (Board s15. 2); 2 — rack (Board s40, 2); 3 — side proleg (20×20 rail, 2 pieces); 4 — lower cross racks (rack 30×30, 2 PCs); 5 side drawer side seat (Board s40, 2); 6 — upper back (Board s35); 7 — mesh (plastic, wicker 550×495); 8 — rail mounting bracket (rail 20×20, place); 9 — cross member of the backrest (Board s20); 10 — mesh seat (plastic, wicker 495×440); 11 — drawer side rear seat (s40 Board); 12 — drawer side front seat (timber 60×60); 13 — proleg (strap 30×20); 14 — front foot (Board s40, 2 PCs.)

In the upper and middle part of the legs the markings are prepared nests for shipovyh connections with mating parts of the seat and the side transverse proleg, and the bottom holes for the furniture bolts for connection with outdoor arcs.

The side-bar

The main one is connecting the front legs to the uprights. They also have a slight bend, suggest the same scale grid. In its markup of the sawing is performed similarly to the described details. Profile rings according to the seat most convenient form.

At the ends of the rings are the flat spikes for connection with the legs and uprights.

Below are PRONASCI side — bars or round rods connecting the legs to the uprights (a simple spike).

Crossmember

This includes all other parts, the connecting rack and legs.

So, stands two of them. Top, wide, medium and narrow, have a slight bend, which gives the back a more convenient form. However, the bending is not associated with such a difficult operation as the bending part. The concavity of the middle part of these cross-beams can be obtained by vystragivaniem these areas of workpieces with small plane and dracopoli file.

The third cross bar racks — part of the seat frame. It is not bent and the ends on both sides of a flat connecting tongue.

Finally, the lower cross struts are designed for fastening that part, which performs the role of the rear legs. It can be a small section of bar or round rod, connected to the uprights by a simple thorn.

The front legs of the upper cross member element of the seat frame. This bar, the front edge of which is smoothed using a plane — to get some fillets on the front face for convenience sitting. At the ends of the flat spikes for connection with the legs.

About the middle of the legs connects flat proleg also with finger tips under the nest on the legs.

Assembly

As already noted, almost all the details of the chair are joined together with simple flat thorn. The strength of such connections will depend on the elaborateness of the spikes on the ends of the parts, and the respective jacks under them.

To ensure the connection strength, the Assembly finger-knots is made with the use of glue or carpenter’s PVA. The excess of it, addressing the parts are removed immediately.

Finish

All the blanks before Assembly are carefully processed, if necessary, planed and polished by sandpapers with decreasing grit abrasive.

After prolonged drying (for better adhesion of the adhesive joints) you can start the final finish of the swing. It is the painting of parts or nitropaints and enamels in several layers, with intermediate drying (and if necessary, additional grinding of the surface a fine-grained emery paper or glass chips).

However, the most advantageous trim (if this is consistent with the environment of the interior) — dark furniture varnish or pre-tinted wood stain and subsequent varnishing in several layers, also with intermediate drying and topolyovka.

In the last turn on the ground back and seat nailed a solid mesh of natural fibers or synthetic materials; fastening — by means of racks and furniture nails with hats hammered with a rather common step, providing the necessary holding power.