Perhaps one of the most ancient and at the same time, and still most common methods of connecting parts of machinery, parts, tools — mount rivets. Is riveting, as a rule, the percussion method.

Perhaps one of the most ancient and at the same time, and still most common methods of connecting parts of machinery, parts, tools — mount rivets. Is riveting, as a rule, the percussion method.

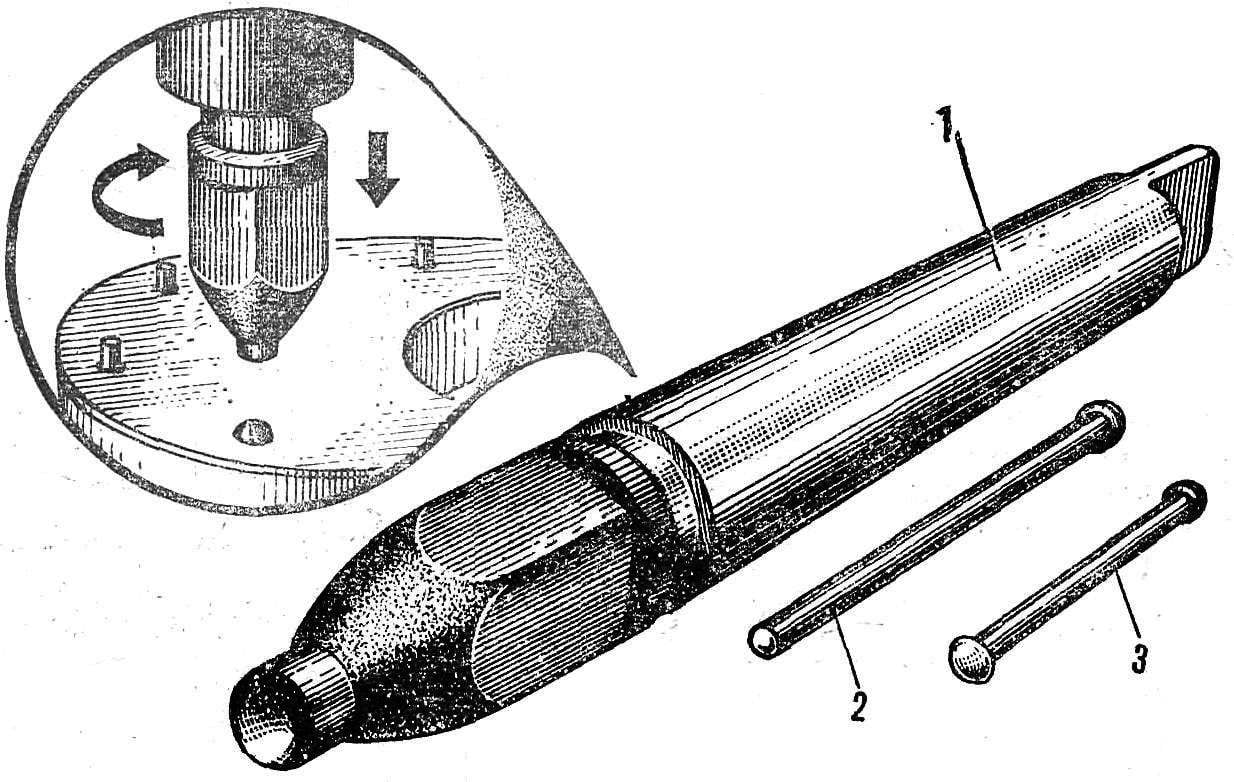

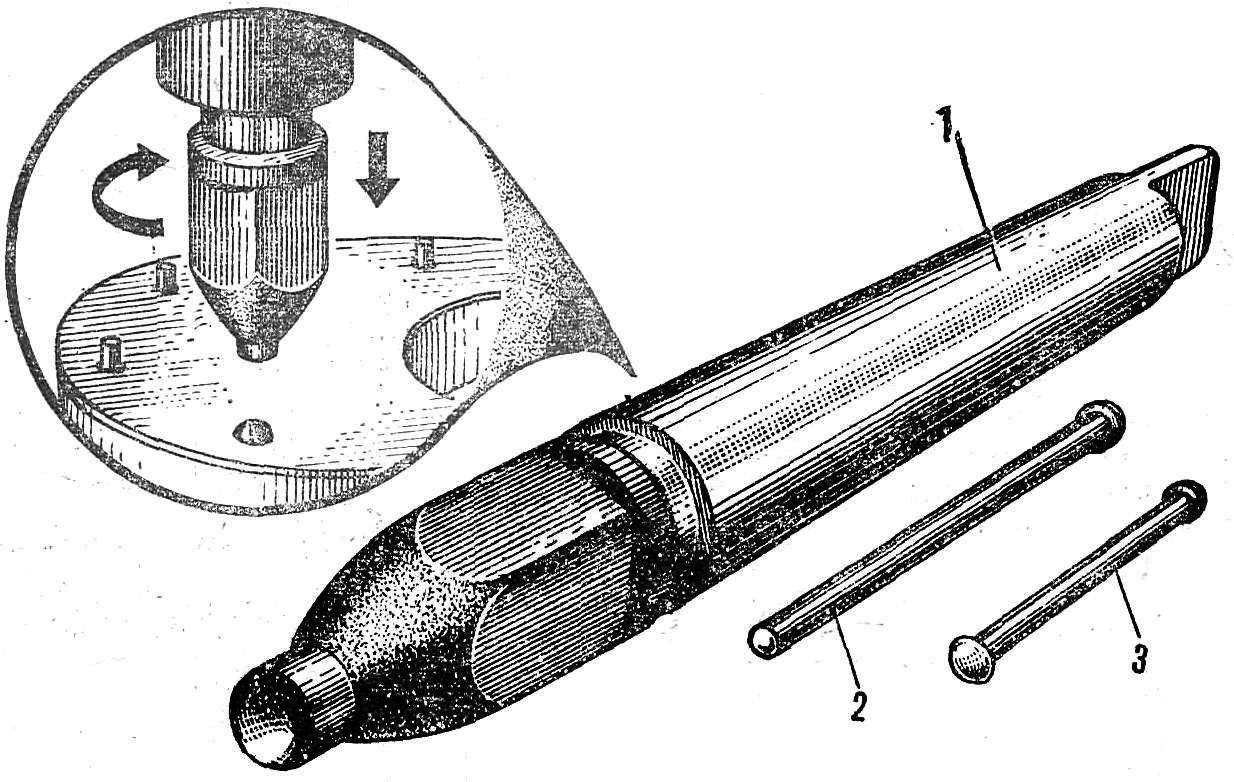

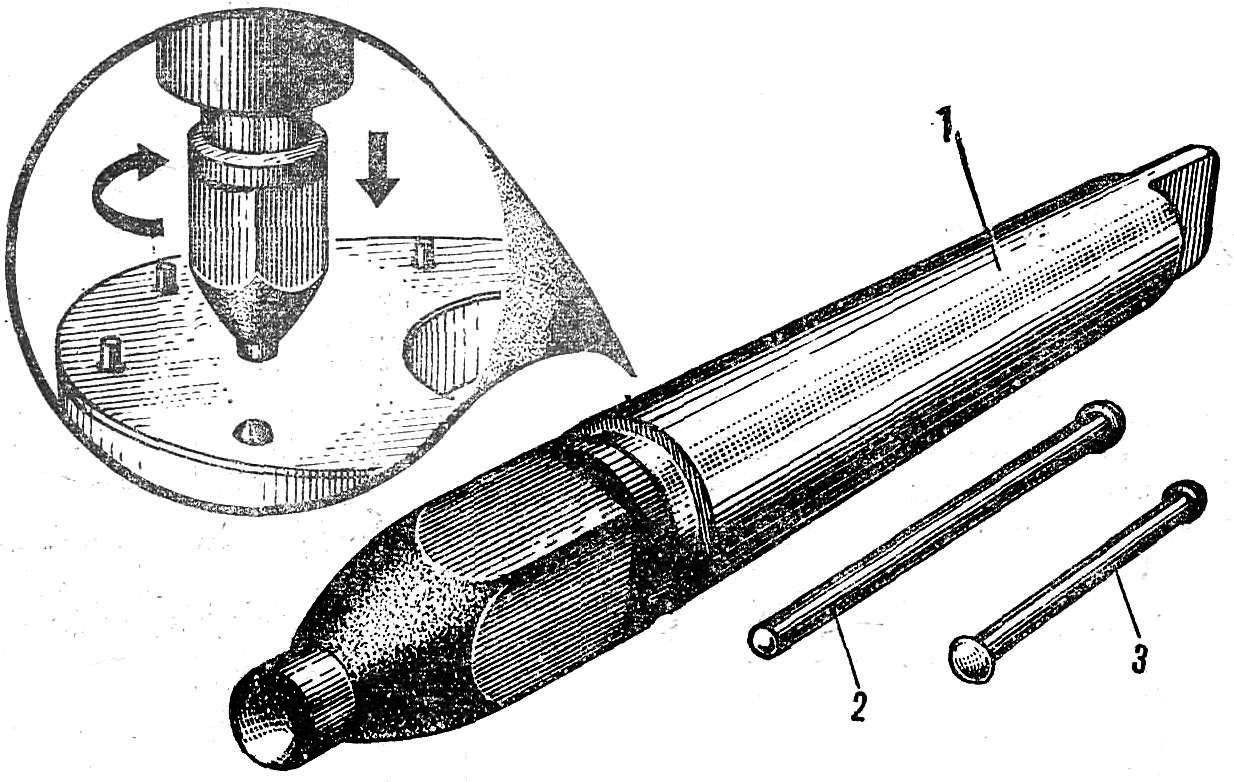

At the Moscow plant of automatic lines decided to use more modern technology. In recent years, increasingly introduced friction welding, when the rapid rotation of both surfaces of metal in contact are heated to reflow and cooling down, firmly grasp each other. In this way, the factory innovators and proposed a flared rivet head. This was done using drilling machine in which the cartridge is inserted into the forming tool. At high speeds it is pressed by the working head to the rivet, and forms upravlyaet it.

The Rotary “spin”:

1 — head, 2 — axis hinges, 3 — rivet.

New method tested on the site, where do padlock and rivets were processed manually. Productivity has doubled, greatly improved the quality. Not smaller effect was achieved and the processing axis of door hinges and other parts such as the head of the bolt. By rotating flaring their steel fabricating on a lathe, which gave the opportunity to raise the productivity of these operations 5 times.