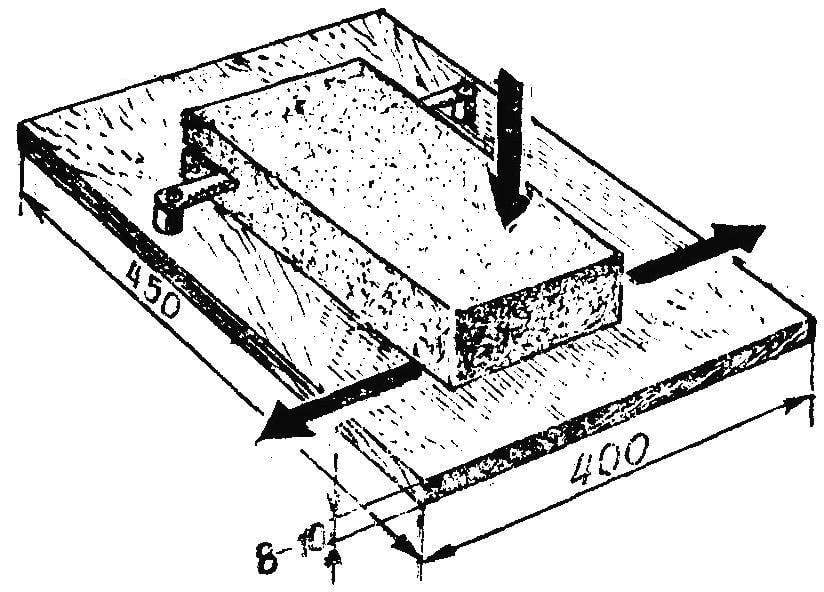

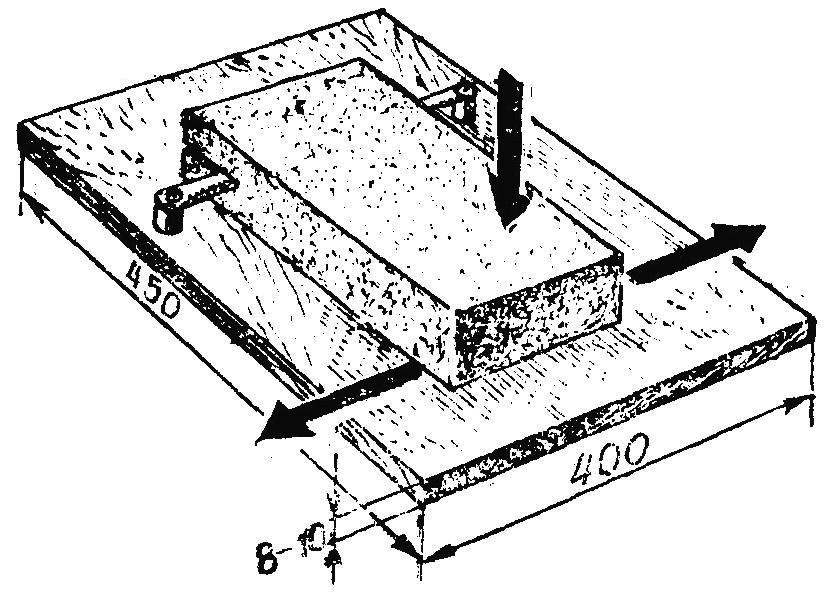

Very often the modeller and the young designer may need to saw a block of foam into a thin plate. The easiest way to do the proposed adaptations. The sheet of plywood with a thickness of 8-10 mm drilled two holes Ø5—6 mm at a distance equal to center-to-center size of the saw blade, and screws M4 attach the canvas. Under his pre-placed washers on the thickness of the future plate.

Very often the modeller and the young designer may need to saw a block of foam into a thin plate. The easiest way to do the proposed adaptations. The sheet of plywood with a thickness of 8-10 mm drilled two holes Ø5—6 mm at a distance equal to center-to-center size of the saw blade, and screws M4 attach the canvas. Under his pre-placed washers on the thickness of the future plate.

Pressing the block of foam to the plywood and the saw blade to the canvas, make the longitudinal motion. For work it is better to use a new, unused blade. If necessary, the plate can be further treated coarse-grained emery paper.