So the designers of furniture invented various “Autonomous” gusset.

The most common angle screed.

Standard furniture corner tie is a fixing unit, which is familiar to the house master who had to produce Cabinet panel furniture or to collect the same factory. The site consists of a corner (pressed steel or cast aluminum), two threaded bushings (steel, aluminum or plastic) and a couple of steel screws M6.

Shelves in corners drilled and countersunk holes with a diameter of 6.4 mm under the M6 screws, and one hole is cut through the groove. This groove facilitates the Assembly of products.

The figure shows the aluminum die cast area, but if necessary it can be manufactured from a steel strip 3 mm thick or aluminium of area 30×30 mm.

Threaded bushings of any material have an inner thread M6. And outside they are decorated in different ways: on the steel bushing is threaded M12 on the aluminum — screw-thread (like screws) on the plastic ring of triangular grooves (herringbone).

Corner furniture screed:

1 — area (steel, sheet s3 or dural area 30×30); 2— screw M6 (2 pieces); 3 — horizontal bar; 4 — threaded bushings (steel, aluminum, plastic); 5 — side panel

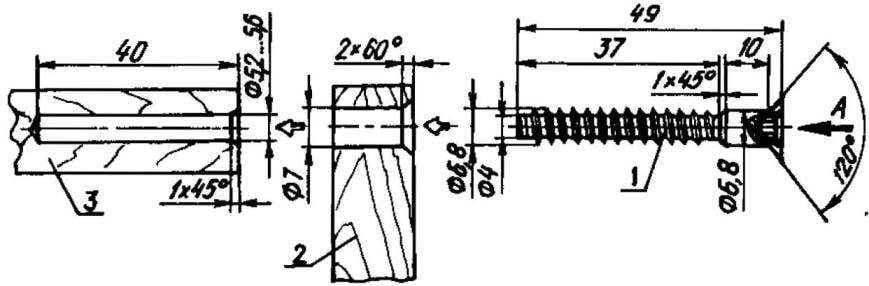

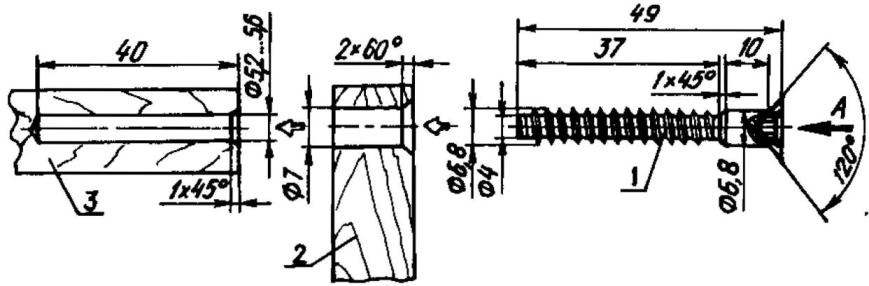

Homemade drill bit for screw coupler:

1 —blade (high speed or tool steel, strip s2); 2 — the shank (steel, rod d6); 3 — bolt M3

Sleeve in different ways embedded in the body of the shield or panel. Steel sleeve screwed a hex wrench for the side threaded holes made by the Jack. Aluminum — standard screwdriver to which the upper end of the sleeve is slotted the slot. Plastic just driven into the holes of the socket. The walls of the holes or the outer surface of the bushing is pre-lubricated with glue (PVA or universal).

Dense docking parts of furniture when assembled with corner ties depends on the correct layout and fabrication of blind holes (cavities) under the threaded sleeve.

As in any business, there are some small secrets. Given these, the work can be done not only faster but, more importantly, quality.

Marking is best done on a specially made template to the conductor. But if the amount of work is small, then this can be done using the area of the screed. For this, the abutting parts are to be set strictly at a right angle to each other (via the assistant or on the desktop, moved close to the wall, after checking the perpendicularity between them). Selecting the area to place a pencil or a Cairn to identify the centers of housings threaded bushings in the shelf area with a groove coinciding with the center of the round hole; flange without groove, it is necessary to distance from the center of the circle (and, hence, the plane of the mating parts) 2 mm, nearly the circumference of the circle.

After nicardipine spaced points in features drilled nest under the threaded sleeve with a diameter of 10 mm and a depth of 12 mm. perform this operation on the machine no problem usually does not cause.

If with a hand drill (mechanical or electric), then installing on the mechanism of the limiter, again it is better to make a guide hole drill with a diameter of 4-5 mm, and then drilled them to the required diameter and depth. (It is useful to recall that the axis of the hole must be strictly perpendicular to the plane of the part.) Given the depth of the socket will provide special emphasis that are sold in a kit with a drill. If such emphasis is not, then you can make wooden restrictive sleeve, putting it on a drill. Without these devices dramatically decreases the performance, as you have to work with great caution and continually measure the depth of the nest, so as not to drill through.

And the last one. Before install the threaded bushing in place, should be a little razzenkovku hole. This will provide perpendicular entry of the sleeve into the socket, facilitate the screwing of the metal bushing and will eliminate the swelling of the panel material around the hole.

Not so long ago in the furniture connection. First, import — called “confirmat”, and then and domestic. And those and others are one piece — special screw. The shape of these helical ties resemble large screws without lead-in conical part with a smooth helical surface.

Instead of a slot in the head of this tie is made socket Allen key.

Not only Amateur designers and professionals that manufacture furniture to order, quickly appreciated the technological advantages of helical ties to quickly assemble a variety of items of furniture. Visible at all times remain only a beautiful chrome surface screw heads, and then only on the side surfaces. But when you close the plastic covers for the color of the material.

The most critical pre-surgery marking and making holes for the screw coupling of the mating parts. The drill diameter for the nest under the threaded part of confermata in the longitudinal parts of the product (relative to the axis of the screw couplers) are chosen based wood parts (panels): 5.6 mm — for solid, 5.2 mm — for soft. If the items (panels) made of chipboard, then drill to sharpen them like solid wood, if of fiberboard, soft.

In a longitudinal panel socket drilled in the middle of the thickness, its axis must be strictly parallel to the surfaces of the part. When a large amount of work for this operation is also possible to make a template.

In the lateral parts drill a through hole with a diameter of 7 mm. and Its centre set on the distance from the edge part, equal to half the longitudinal thickness of the part. But in practice it is better to add another 1-2 mm. the eye of the derogation in the assembled furniture will be invisible, but the margin of safety would give a significant.

Restrictive bushing for drilling sockets for threaded bushings:

1 — drill d10; 2 — restrictive sleeve (the wood is soft rocks); 3 — an electric drill Chuck

Furniture screw coupler:

1 — coupling; 2 — transverse bar; 3 — longitudinal panel

If the part is solid wood or chipboard, the hole in it on the front side senkut, so that the screw head was flush. For soft wood you can do without a countersink and the head should be embedded when screwing the tie.

The total depth dimension of the slot and the thickness of the transversal parts must be at least 10 mm greater than the entire length of the turnbuckle.

When drilling holes for screw couplers lot of time and effort spent on tool change. Therefore it is better to make a universal drill-countersink bit. They can drill holes in the transverse and longitudinal panels and countersink them alternately or simultaneously, docked and fixing details (with the assistant or, again, at the wall) at right angles.

When you are designing furniture products dock loaded parts (e.g., shelves and bottoms) tableware and bookcases to perform better on the furniture corners, as the hole for the screw coupling significantly weakens the connection. At the same time, little shelves loaded with a variety of open niches of furniture, shelving units, shelving better to mount screw-on ties, because the parts they do not decorate

A. POLIBIN

Recommend to read RESCUE TUBE In the "M-K" № 8 for 1988 has published an article about the restoration of the working head Wellenreiter. Offer an easier way to "restoration" with one or two tubes of lemonade or... FRONT AXLE GOVERN ITSELF The car's handling and tyre wear, as we know, primarily depends on the state of the front suspension of corners of a longitudinal inclination of axes of rotation, and angles of camber...

Modern furniture – cabinets, tables, shelving made from chipboard or fibreboard, plywood, wooden boards, etc. however, many traditional corner joints (tenon-eye, vpoldereva on the dowels, keyways and others) are not only very time consuming, but sometimes their use is simply impossible. In addition, all these compounds the monolith that it is often very impractical for transport and even moving furniture.

Modern furniture – cabinets, tables, shelving made from chipboard or fibreboard, plywood, wooden boards, etc. however, many traditional corner joints (tenon-eye, vpoldereva on the dowels, keyways and others) are not only very time consuming, but sometimes their use is simply impossible. In addition, all these compounds the monolith that it is often very impractical for transport and even moving furniture.