First of all, the convenience and the possibility of rational allocation of the apartment: the furniture as if “embedded” in the place. Moreover, it is made of the available materials and standardized blanks, characterized by low complexity of the preparatory operations.

It is quite possible to consider technological and Assembly: the joints are mostly made on the screws, which is easy to do, and therefore available even to people without special skills.

The same applies to the decoration of furniture. The front surface is covered with one layer of furniture Polish on previously polished surface. In all other places the wood is left just planed that justified from an environmental side.

Did not require any special tooling. It was enough of DIY tools: handsaw, planer, hand drills, screwdrivers, rasp, gon, tape, rulers, etc. Available and used components — the usual screws and a commercially available hardware— “card” and “piano” hinges, magnetic latches, handles, hooks.

Fig. 6. Node E.

Fig. 7. The Node F.

Fig. 7. Node G.

Also important is the ability to upgrade: if necessary, the design can be easily disassembled and transformirovalsya, not to mention the fact that a set implies further development on the principle of “build-up” due to additional pieces of furniture.

MATERIALS

As the raw materials used Board section 170×20 and 100×20 mm, bars 50×50, 30×30 and 20×20 mm, timber (boards with quarter) 50×20 and 100×20 mm — all softwood (preferably pine); and plywood thickness of 4 and 10-12 mm birch or pine. The initial billet obtained by simple sawing across. Only in cases when it was not possible to procure the required timber cross sections, I used the sawing along with the subsequent planing of edges. All surfaces of pieces of lumber planed, and the front surface, as already mentioned, buffed with sandpaper.

ASSEMBLY CONNECTION

All designs are made on the basis of a unified Assembly of four connection types.

Option “A”. Is a compound of boards or slats “Plast-Plast”, overlapping, perpendicular (Fig. 1) or parallel (Fig. 2) the location of the edges of the abutting parts. Screws if this screwed in from the inside of the structure, which provides additional operational benefits and design. Although if you have a special furniture screws (with decorative cover) the reverse option.

use of boards and battens “butt-faces” in the corner (Fig. 3). Flush to the base end of element 1 for more detail pristykovyvayas 2 through the auxiliary element 3 — all of them are fastened with screws 4 and 5.

Option “C”. Suitable for joining boards or slats “Plast-edge” in the area, or t (Fig. 4). To the base element 1 by the end of the mounted detail 2 screws 3. The number of screws is determined by the length (or width) of attached items; the distance between the screws 100 to 120 millimeters.

Option “D”. Enables the connection of the boards or slats “Plast-end” in the corner “in the castle” (Fig. 5). In the rack 1 is embedded in the shelf 2. In this case the side edges of the rack are cut to a depth equal to the thickness of the Board and Plast stands at the crossroads — for 6-8 millimeters.

When the pull-tight “lock” works well without fastening elements. If necessary, the connection can be strengthened with screws, screwed in from the edges of shelves or plastic racks.

ASSEMBLIES

All of the designs used standardized sub-assemblies.

Node “E” (Fig. 6). Is strips 1, which are attached to supporting bars 2 with screws 3. With the additional through holes in the bars of the node can be attached with screws to the other elements of the design.

The node “F” (Fig. 7). It’s a shield, a cohesive boards 1 (in quarter) with 2 straps and 3 screws (at least two screws on each end of the Board). The location of the boards is vertical.

Figure 9. Wardrobe-shelving:

1 — front 2 — bar frame; 3 — shelf; 4 — strip spacer; 5 — bar

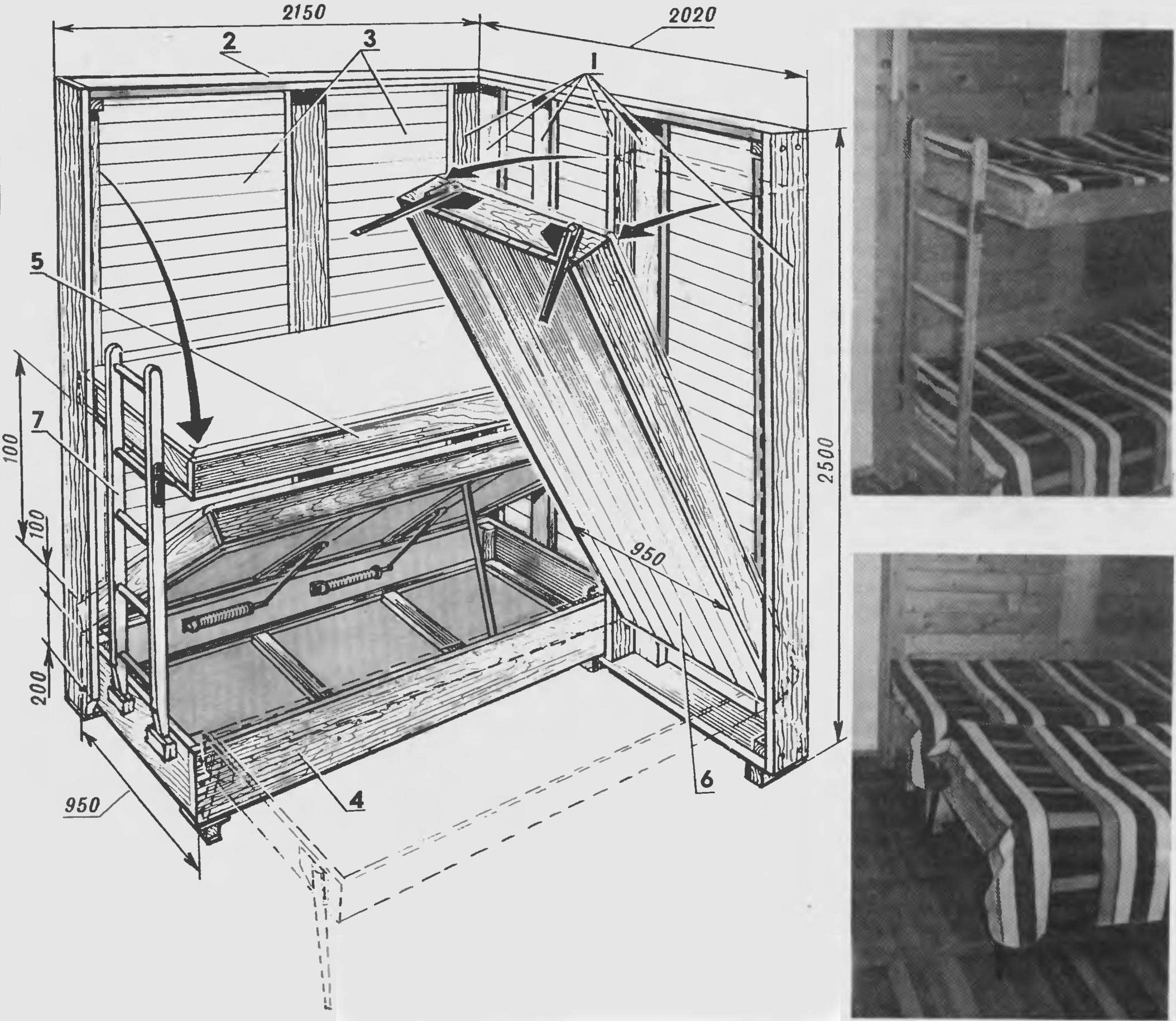

Fig. 10. Sleeping unit:

1— stand; 2 — tie horizontal; 3 — wall – shields; 4 — bed, couch; 5 — bed top, hinged; 6 bed lowering; 7 — ladder.

Fig.11. Closed case:

1,3 — stand; 2 — ligament stands; 4 — panel side; 5,6 — door Cabinet; 7 — doors attics; 8 — the front wall of the mezzanine.

Node “G” (Fig. 8). Option shield with a horizontal set of boards in the quarter, rallied flush with the vertical rack connection usage And stand 1 dovetailed with the 2 boards due to overlapping butt straps 3 attached by screws 4 (and on each Board have two screws on each end).

Below are specific designs that use the described parts and components.

BOOKCASE-DISPLAY RACK

The Foundation of the structure (figure 9) is a closed frame with two uprights 1 and horizontal panels 2, connected for option “B”. Embedded in rack seven shelves 3 at the option of ports “D”. Facing the wall side of the frame is sheathed on nails plywood thickness of 4 mm. To increase the bearing capacity of the shelves between them the auxiliary spacer strap 4, and under the lower bar — 5 bar.

SLEEPING FOLDING MONOBLOCK

It consists of two vertical panel frame (Fig. 11) formed by uprights 1 and horizontal ties 2 (similar to a bookcase) wooden shields 3, United by node type “E”. Drawn to each other by the angle they form a rigid structure that does not require attachment to the walls of the room.

Along one of the shield walls is located a bunk bed: bottom 4 is made as a locker daybed, top-5 — folding. The second shield wall along the hinges mounted in a vertical position is another, descending 6 bed All beds are wooden boxes designed for polutorospalnye mattress; the daybed under the cover is a box for bedding. The couch is mounted directly on horizontal ties both shield walls and only one free corner is provided with a support leg Falling to the bed leans on metal feet, two-lever, and folding bed on the couch on the stairs and additional emphasis on one of the pillars of shield wall (in the figure not visible). Since the folding bed in the daytime could be raised a ladder to her it is better to provide removable.

The cover of a couch-locker to facilitate lifting of the better to provide spring-loaded levers, and to hold in raised position — the simplest stop-locking mechanism in the form of a wooden or metal rod.

The legs of the movable bed easier to make the swivel, with emphasis in the rim of their plate-bracket.

The lower side of the folding and dipping of beds for ornamental purposes are covered with boards: in the raised position, they blend in with the wooden walls of the sleeping unit.

The same technology made me a set of furniture for kitchen (cabinets, tables, bedside tables), wardrobe-Desk, wardrobe-entrance hall, bedside table under the drawing Board and TV. As you can see, the possibilities and the variety is diverse enough.

WARDROBE WITH ENTRESOL

Construction (Fig. 10) made on the basis of a surround frame formed of box-sidewalls of the wide of the uprights 1 and inlaid panels of 4 boards between them, the horizontal bundles of strips 2 and a superimposed narrow racks 3.

The connection of the horizontal cords with the stand — by option “A”. Double door Cabinet 5 and mezzanine 6 and 7 represent a shield made as the nodes “F” and the wall of the mezzanine 8 — how to node “E”. The other Cabinet walls and mezzanines inside of the plywood; shelves are plywood with a thickness of 10 mm. All the leaf hinged to the corresponding frame elements with hinges.

Internal decision of the Cabinet depends directly on the functional purpose of its sections. For example, if side compartments for dvustvorchatye doors are designed for storing clothes have installed metal or wood a horizontal rod to accommodate the hangers, and at the doors mounted on the small bosses of the rail under the ties, scarves, belts. Middle section — for bedding, equipped with an appropriate number of shelves. And the amount of mothballs it is better not to break — then they will be more roomy.

Recommend to read ATLAS PROFILES Profile "CRD-2". Developed in 60-ies of the Western European model airplanes especially for rezinomotornaya models. This profile is also recommended for glider models of a class "A-1". ... TWO-HANDED — AS A HACKSAW As proposed in the journal version of the work alone on the two-handed saw (with a rubber strap or tape) is not very suitable for winter, Thai rubber in the cold loses its elasticity....  Getting to self-designing furniture, I set a goal to achieve maximum adaptability to design was designed, manufactured, and operated with the lowest cost. I designed a set of furniture for a Studio apartment meets this requirement, I think, according to the following criteria.

Getting to self-designing furniture, I set a goal to achieve maximum adaptability to design was designed, manufactured, and operated with the lowest cost. I designed a set of furniture for a Studio apartment meets this requirement, I think, according to the following criteria.