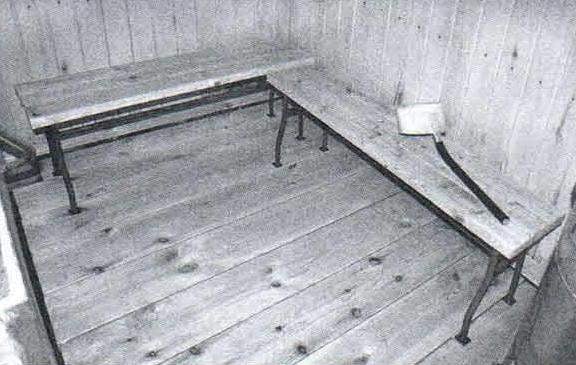

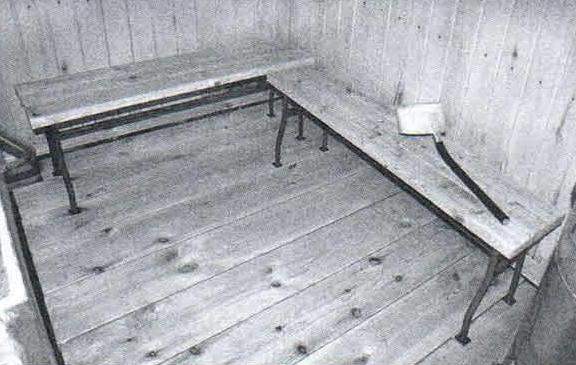

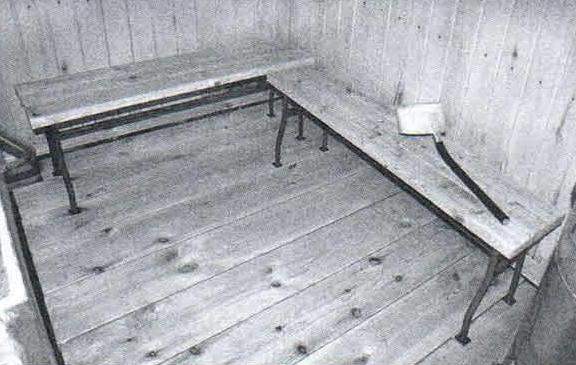

Rotted benches in the dressing room… they were Made according to the ancient traditions of larch boards, comfortable, firmly put together and seemingly eternal. But the legs on the bottom and top and seat stitching has rotted. Besides, it turned out that their was a massive screen for the heat from the stove. In the end, the paneling behind the stands, do not dry, plesnila and spoil it. To address these shortcomings, I decided to make a new shop with metal legs and durable, and will not rot. The design will be “transparent” to heat flow from the stove to the walls behind the stands. Still, the metal has a property easy to heat up, accumulating heat, which will allow you to quickly dry the intersection of the legs with the seats and floors.

Rotted benches in the dressing room… they were Made according to the ancient traditions of larch boards, comfortable, firmly put together and seemingly eternal. But the legs on the bottom and top and seat stitching has rotted. Besides, it turned out that their was a massive screen for the heat from the stove. In the end, the paneling behind the stands, do not dry, plesnila and spoil it. To address these shortcomings, I decided to make a new shop with metal legs and durable, and will not rot. The design will be “transparent” to heat flow from the stove to the walls behind the stands. Still, the metal has a property easy to heat up, accumulating heat, which will allow you to quickly dry the intersection of the legs with the seats and floors.

Material for the frame of the new benches was water galvanized pipes of an external diameter of 22 mm, and the material for the seat – a pine Board 100×40 mm. as additional elements used angle area 25×25 mm and sheet stainless steel thickness of 2 mm.

Work carried out in this order:

– sawed off three blanks with a length of 1200 mm from the Board-section 100×40 mm, planed surface, removed the chamfer, blunting edges, carefully sanded (“berry”own);

– impregnated boards antiseptic composition of water and copper sulphate and left to dry in the sun;

– cut four blanks for the legs out of the pipe with a diameter of 22 mm long by 420 mm with two blanks for cross bars at 180 mm and one proleg length 1055 mm;

– strip the ends from burrs, laid side by side, and outlined with chalk the fold line;

– using a simple vise and bending gave each leg a curved form, using the first as a template for all others;

Rotted benches in the dressing room… they were Made according to the ancient traditions of larch boards, comfortable, firmly put together and seemingly eternal. But the legs on the bottom and top and seat stitching has rotted. Besides, it turned out that their was a massive screen for the heat from the stove. In the end, the paneling behind the stands, do not dry, plesnila and spoil it. To address these shortcomings, I decided to make a new shop with metal legs and durable, and will not rot. The design will be “transparent” to heat flow from the stove to the walls behind the stands. Still, the metal has a property easy to heat up, accumulating heat, which will allow you to quickly dry the intersection of the legs with the seats and floors.

Rotted benches in the dressing room… they were Made according to the ancient traditions of larch boards, comfortable, firmly put together and seemingly eternal. But the legs on the bottom and top and seat stitching has rotted. Besides, it turned out that their was a massive screen for the heat from the stove. In the end, the paneling behind the stands, do not dry, plesnila and spoil it. To address these shortcomings, I decided to make a new shop with metal legs and durable, and will not rot. The design will be “transparent” to heat flow from the stove to the walls behind the stands. Still, the metal has a property easy to heat up, accumulating heat, which will allow you to quickly dry the intersection of the legs with the seats and floors.