So, you will need three shield 1700X850X15 mm: one will become the back the back of the sofa, the second seat and the third will be used to manufacture the sidewalls and bottom of the front wall. For this shield you must cut in half and from each half cut off on the band 250X850 mm: these strips make up the front wall of the base, and the remaining part size mm 600Х850 will serve as sidewalls. The angles of the back and the side of the spila.

For clamping workpieces in the corners and in the middle of the bars use 40X40X250 mm, single bar length 820 mm will go to the cross support of the seat.

A preform base, B — base assy.

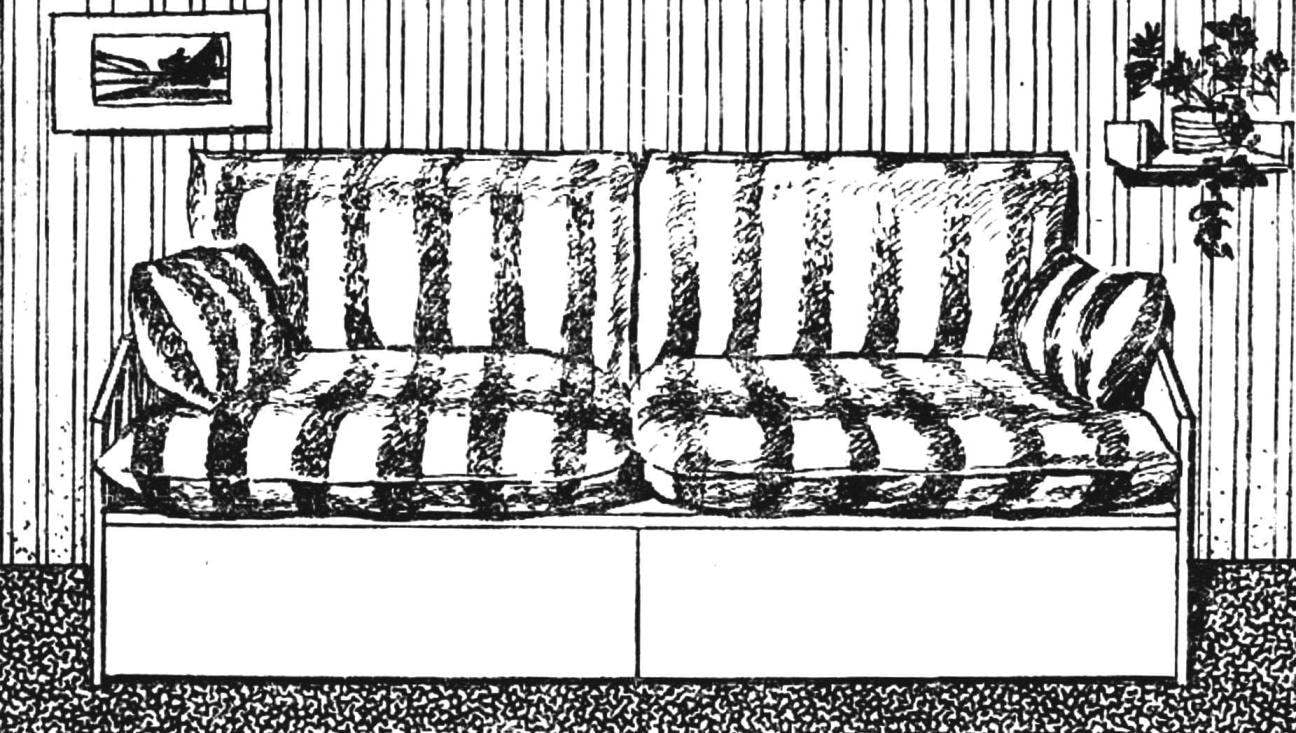

Fig. 1. The scheme of the sofa:

1 — the front wall of the base, 2, 5 — bars Assembly, 3 — cross reference bar, 4 — side, 6 — back, 7 — corner, 8 — seat.

The build order is clear from the figure. To connect all parts it is better to glue with screws or M5 bolts with round heads, in either case you must first do the drill the appropriate holes. For fastening the upper part of the sidewalls with the back possible to use metal (duralumin) area.

The final appearance of the sofa will give a soft pillow: large four — seat backrests and two small sidewalls. It is better to sew from mattress fabric, teak, choosing its colour Gud color wooden pieces. The dimensions of the pillow are adjusted to the dimensions of the sofa, but after stuffing them with foam, they are somewhat played for wooden edge.

DOUBLE BED

When the room is a good layout, the so-called square, store-bought furniture will easily fit in its area; harder to beat the “equalizer” — elongated, elongated room with inconveniently placed Windows. The most “intractable” place — angle.

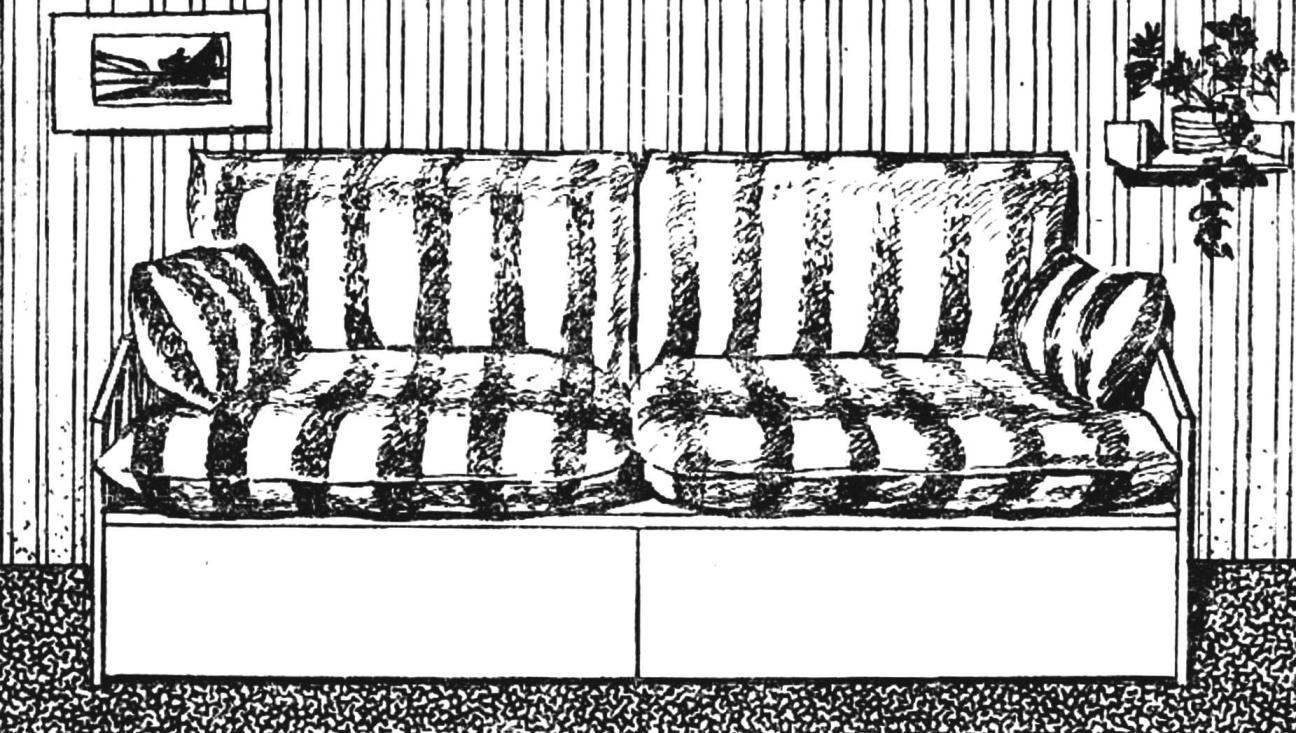

One of the variants of its solution and may be that’s the double-sofa, made of two identical modules-boxes. Ndwiga to corner one of them and put in the second, we don’t just make the two sofas together, and formed a kind corner Suite: table, chair and sofa. It turns out cozy and practical. And when you consider that within each hide bedding, then at night, a corner can turn into the bedroom. Depending on these features should be made corresponding adjustments in the driven dimensions of the module. What’s he going!

It is based on a frame made of two longitudinal boards in the sizes 1500Х400Х15 mm and two mm transverse 670x400X15 connected with metal corners. The bottom is sewn to the frame with nails or screws the bottom of the plywood 1470X670X3 mm with reinforcement along the edge of the longitudinal rails 1470X30X30 mm Board 670X367X15 mm.

Fig. 2. Corner sofa and its module:

1 — longitudinal Board of the base, 2 — bottom, 3 — cross base boards, 4 — corner, 5 — seat.

The top shield-the seat can be made also from plywood 10 mm thick or particle Board (with the obligatory staining with the two sides enamel paint). If you use thin material, the shield is necessary to strengthen the bottom transverse bars 660X40X30 mm, attaching them with nails “Usagi” small screws or glue.

On the sofa, if necessary, can be made flat foam cushions in cloth covers.

WARDROBE

And here the box has the correct form of a cube, allowing to make of it the most different items of furniture: it can be a bedside table, and a vertical pencil case for domestic detail, and bench — out of several placed together and covered with pillows of “cubes”, AND a BOX for shoes and a bookcase, and a stand for the radio. Depending on the destination solved the front panel and the internal structure of such a module: the doors are hung, are attached to side rails for drawers, vertical partitions for offices.

Fig. 3. Wardrobe of “cubes”:

1 — bar, 2 — module, 3 — in wardrobe.

The Foundation module consists of four covered pack or enamel panels: two side, top and bottom, made of chipboard with a thickness of 20 mm or corresponding plywood; the size of each panel 500X500 mm. the Rear wall can serve as hardboard, thin plywood, sheet plastic; and some of them are made of walls, bottoms of drawers. They are inserted in the prepared box or in the main frame grooves. Load-bearing panels are joined so that the top rested on the vertical, and they, in turn –on the bottom: firmly and securely.

Recommend to read MINI-MOKIK ON LAND AND WATER… Mini makiki always use the boys great success. And for good reason! Small size, cost-effective, modern appearance, excellent performance — what more can you ask for? Maybe that's why many... LITTLE SECRETS OF THE GREAT MASTER In the "Modeller-designer" No. 12'99 edition began publication of a series of materials one of the leading "rocket men" of Russia I. shmatova. Today we continue and offer the...  Even the strongest domestic joiners, boldly undertake to produce on their own shelf, bedside table or Cabinet, do not always have the courage to venture more larger items: couch or sofa, a couch or bed. Meanwhile, modern trends in interior and furniture, giving preference to such basic factors as simplicity of design and functionality, provide attractive opportunities to try their hand in this part of the headset. Here are some examples of readily available solutions that do not require especially high skills and the manufacture of furniture, because the basis of their skeleton — a simple wooden box.

Even the strongest domestic joiners, boldly undertake to produce on their own shelf, bedside table or Cabinet, do not always have the courage to venture more larger items: couch or sofa, a couch or bed. Meanwhile, modern trends in interior and furniture, giving preference to such basic factors as simplicity of design and functionality, provide attractive opportunities to try their hand in this part of the headset. Here are some examples of readily available solutions that do not require especially high skills and the manufacture of furniture, because the basis of their skeleton — a simple wooden box.