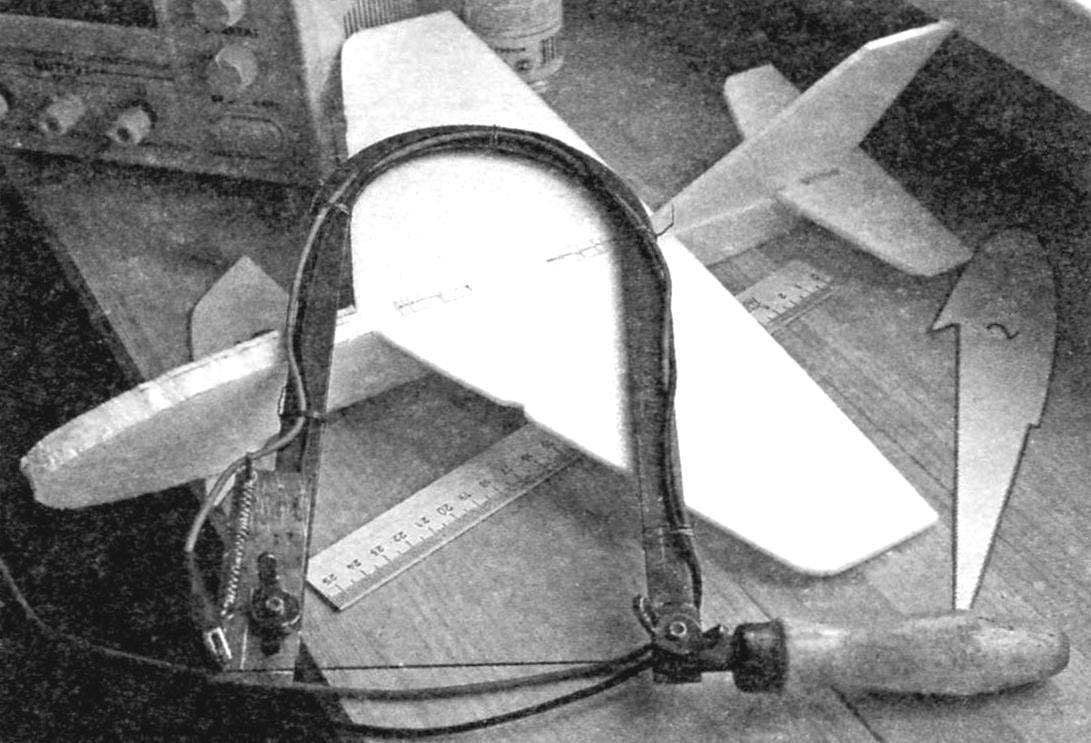

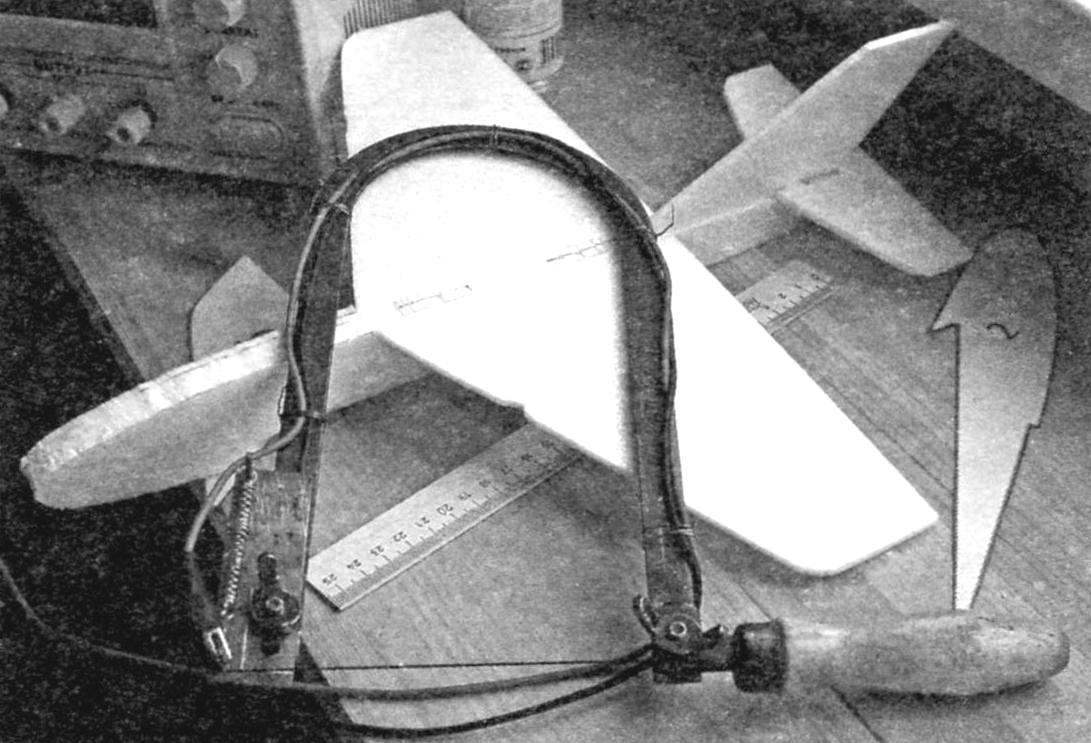

For a long time home of the wizard, use foam, which for all its wonderful qualities has a major drawback. when working, clogging the working area is extremely trudnoudalimyh crumbs. The debris formed even when cutting with a sharp knife, and the use of power tools in General can not speak. The best tool for cutting foam sheets is recognized as the heated nichrome filament, stretched between driven into a wooden Board with two nails. To get the same curved surface or shape cutting, you can use a handheld jigsaw, is equipped with a site for installation and connection of the nichrome filament.

For a long time home of the wizard, use foam, which for all its wonderful qualities has a major drawback. when working, clogging the working area is extremely trudnoudalimyh crumbs. The debris formed even when cutting with a sharp knife, and the use of power tools in General can not speak. The best tool for cutting foam sheets is recognized as the heated nichrome filament, stretched between driven into a wooden Board with two nails. To get the same curved surface or shape cutting, you can use a handheld jigsaw, is equipped with a site for installation and connection of the nichrome filament.

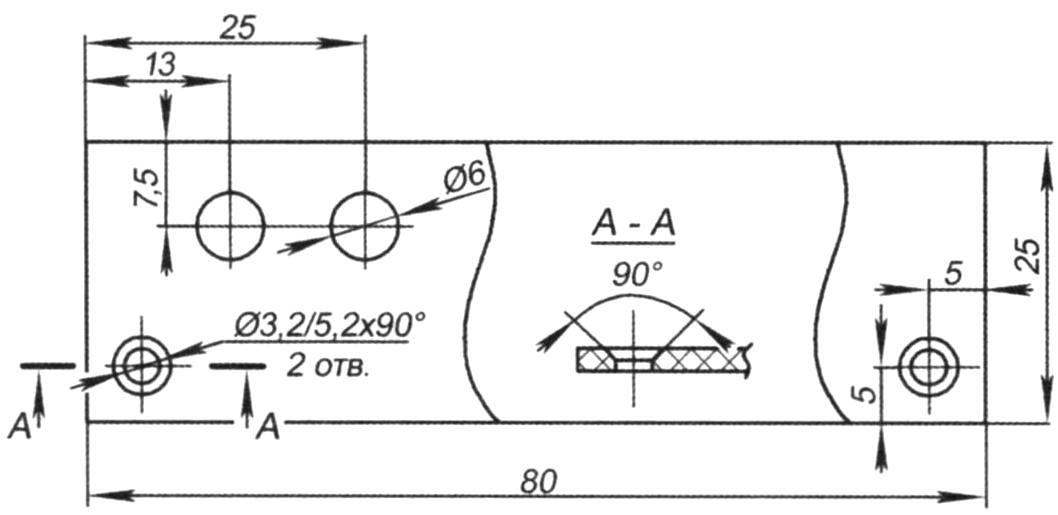

The unit fits into the jigsaw is the front clip attached and the regular nut-lamb jigsaw. In this case, however, you cannot use the hole located 13 mm from the edge node the thread at work touches a lamb and burns, therefore, use a hole 25 mm from the end and put up with some unusual position of the filament. If instead of lamb to take the M6 nut with a smaller outer diameter, this inconvenience is come almost to nothing.

As the basis of the node tension taken two plates from foil fiberglass 2 mm thick. in fact, the foil is only needed on the bottom side of the disc – here it provides the electric contact node of the tensioning frame of the jigsaw. The remaining surfaces of the foil can be removed. In the top plate are drilled and sensource holes for screws M3 countersunk that they utaplivanii in the plate.

Then, with the set screws, the plates are lubricated with epoxy glue and left in a Vice or under pressure until the adhesive has cured.

Since the nichrome wire used in this thermolabile, very thin, then use the usual method of tensioning jig saw due to the compression of the rays of the arc is not possible. For the thread tension, use the spring from the automatic handle. The springs can be carefully straightened rings from 1.5-2 coils on both ends. The first ring is put on the M3 screw, the second is mounted nichrome filament. To apply for a wire tension, a wire podpisatsja to a layer of foil on the lower surface of the plate, and the second wire is set to an alligator clip – it will cling to the front screw M3. Thus, the electrical circuit will follow from the front screw, which passes through a nichrome wire, through the wire, clamp the jig near the handle, on the frame of the jigsaw before contact with the foil knot of tension. Wire to connect to the power source is a flexible, cross-section 1.5 – 2.5 mm2, length 1.5 m. It is attached to the frame of wire segments or collars, so as not to interfere with the work.

After Assembly of the node of the tension and checking the contact between the frame and the plate you can begin installing the nichrome filament. Unlike regular files, thread is best to install it before work and take off after it, as it tears easily.

The preparation for the work developed in the process of testing the following. First, remove the top hold-down node, a jigsaw and a set knot tension. Measured the thread (I used nichrome wire grade 15Н10Х 0.1 mm in diameter) and cut with a margin of 25 – 30 mm. From the node is removed tension spring, the filament tip is inserted into the ring, and the rotation of the spring fingers twisted the end of the wire in 5 – 8 turns. Further weakened the lamb beside the handle of the jigsaw and the second end of the thread clamped so that when the threads over the front screw, the second spring did not reach the rear screws to 5 – 7 mm. with the shearling, pull the thread. Then the front screw crocodile jumped the power wires. Scroll saw ready to work.

Electricity provides thermolastic adjustable laboratory power supply. When referred to in article sizes and material nichrome filament it so happened that when the supply voltage of 10 V the current in the circuit equal to about 0.4 A. Thread not hot, not glowing but perfectly cut foam.

I must say a little about the techniques of working with such a tool. The foam has no heated filament, no resistance, so even random motion can lead to marriage. When you maintain the wire on the cut line of the thread is literally “writing a cardiogram” – hand shake as a result of the heartbeat, breathing, tension in muscles, change of posture and retention of the tool are immediately reflected on the cut parts. Therefore, the line marking details should be protected: on the straights you can use a ruler on the curves – patterns or templates. Rulers and French curves made of plastic can bring – they, too, will melt when you touch their threads, but you can use the templates out of cardboard, wooden rulers, etc. Maybe a good result will give the use of thin metal rulers, if they will not significantly cool the hot thread in the contact zone. Furthermore, it is necessary to keep metal ruler did not concern extraneous metal parts.

It is also worth to mention about the safety measures when working with heating cutting tools. First of all, because this tool has exposed conductive parts, it should apply safe voltage not exceeding 12 V. the application of the step-down autotransformers it is not allowed, because they do not have galvanic isolation from the network of 220 V. For protection from fires should be carefully monitored tool to prevent the touch of the heated filament wires, foreign objects. Good to have on hand in powder or carbon dioxide fire extinguisher (e.g. a car) or other means of extinguishing the fire, while bearing in mind that extinguishing water appliances does not fit perfectly. And finally, work should be done in a well ventilated area, because the foam, when heated, emit noxious and suffocating gas. Be healthy!

N. BEACONS, Ufa, Bashkortostan